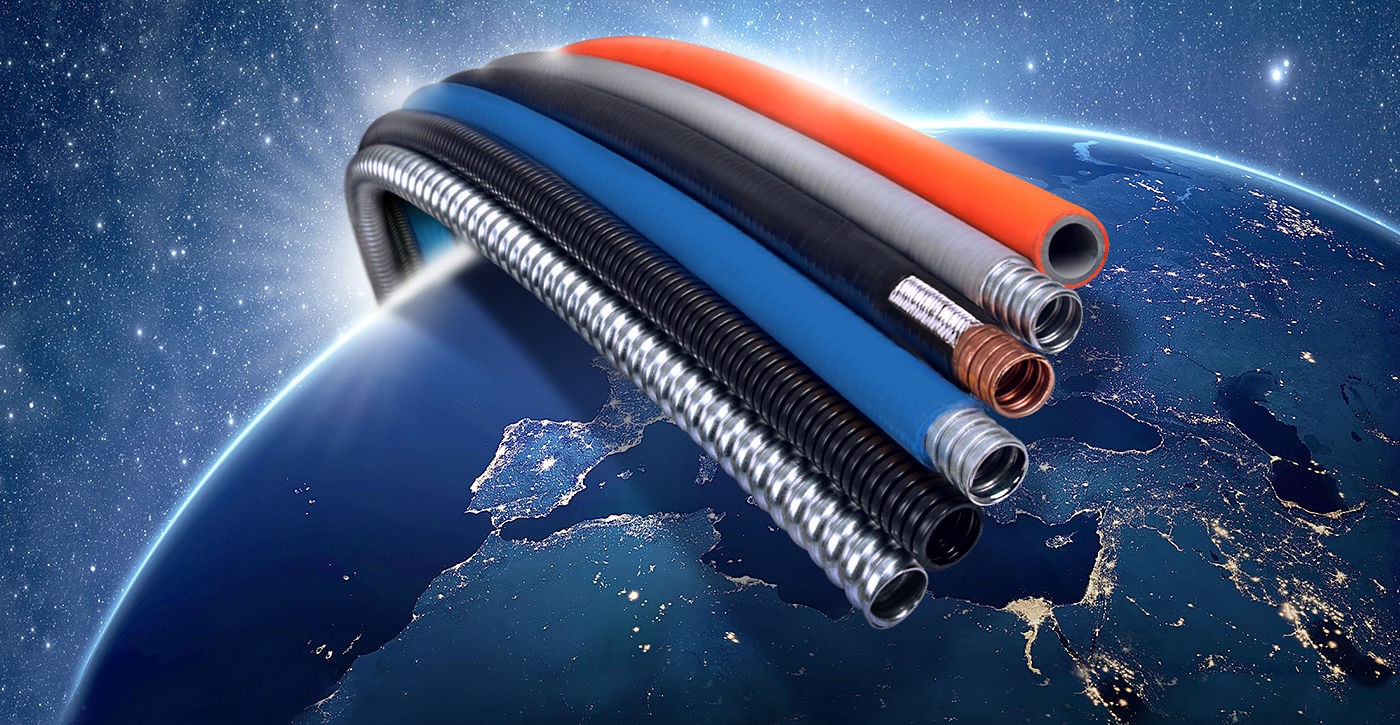

Founded in 1955, Electri-Flex Company has perfected the design and manufacture of its line of flexible electrical conduits, making it a true innovator in the liquidtight conduit industry. The Liquatite® line includes nearly 50 varieties of flexible electrical conduit for contractors, OEMs, industrial maintenance and repair (MRO), government, utility and export users. Liquatite offers the world’s widest range of conduit, including jacketed and non-jacketed metallic flexible electrical conduit, non-metallic PVC conduit, shielded conduit, stainless steel, and non-metallic Corrlok® nylon corrugated conduit system.

Liquatite, by Electri-Flex Company, offers the world’s widest range of flexible electrical conduits, in the following product categories: Jacketed Metallic, Nonmetallic, Unjacketed Metallic, EMI/RFI Shield-Flex, Stainless Steel, and Corrlok Nylon Conduit System. These conduits provide a variety of solutions with the following product specialties:

· High/low temperature

· Halogen-free/Zero-Halogen/low smoke

· EMI/RFI shielding

· Tight spot bending

· Continuous flexing

· UL/CSA

· Smoketight/liquidtight

· Flame retardant and self-extinguishing

· Oil resistance

· UV resistance

· Corrosion-Resistant Stainless

· Lightweight

· Specialty

· Direct burial

Superior Construction and Quality

Our years of applications experience have taught us how to distinguish a superior liquidtight flexible electrical conduit from a less desirable one. As a result, we have developed design methods for our conduit that help prevent common problems. Our unique construction includes:

· More convolutions per foot than other conduit—meaning more steel per foot for greater crush strength.

· Advanced Quality Control—ensuring precise I.D./O.D. tolerances for a superior liquidtight connection.

· Patented Flexi-bond for non-sleeving, non-wrinkling jacket—improving performance and appearance and prevents unraveling.

· Squarelocked and Interlocked inner metallic strip—provides added mechanical strength.

Our vertically integrated manufacturing system gives us complete quality control over every step of the conduit production process, from raw materials processing through assembly. Testing is performed by a team of Quality Assurance experts at each production stage. Every foot of conduit is tested for proper dimensional characteristics utilizing the latest measuring devices.