From SSRs and I/O, to the groov EPIC system, you’ll find Opto 22 products reliable and easy to use. Lower your costs with open standards, less programming, free product support and free pre-sales engineering help. Call us for your next automation project.

Opto 22: Building the future of automation

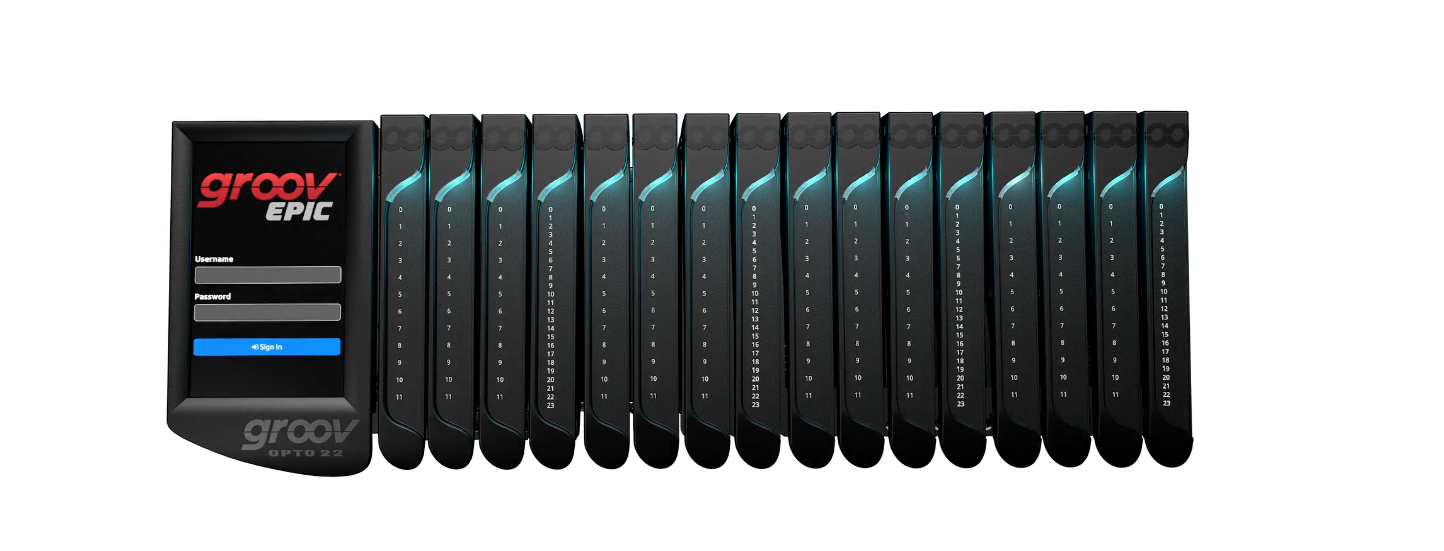

Meet the future: groov EPIC®. For both automation and industrial internet of things (IIoT) applications, Opto 22's new groov EPIC Edge Programmable Industrial Controller gives you all the tools you need in one compact unit.

Edge. Collect, process, view, and exchange data where it’s produced—at the edge of your network. Securely share data among databases, cloud services, PLC systems, and other equipment. Visualize data on the EPIC’s integral touchscreen, on an external HDMI monitor, or from any device with a web browser.

Programmable. Leverage the programming tools you already know; mix tools as needed for your project. Programming options include IEC 61131-3, field-proven flowcharting, C/C++, Java, Python, Node-RED, and more.

Industrial. Place groov EPIC just about anywhere. With its UL Hazardous Locations approval, ATEX compliance, solid-state drives, wide -20 to 70 °C operating temperature range, and stainless-steel construction, EPIC can handle industrial challenges at the edge.

Controller. Rely on real-time control and I/O from people who understand your job. Simplify wiring, commissioning, and troubleshooting with features like EPIC’s integrated high-resolution color touchscreen, wireways for 28-14 AWG, diagnostic LEDs, and hot-swappable I/O.

Built from the ground up to connect automation systems to enterprise IT and cloud systems, groov EPIC lets you:

Reliable hardware, easy-to-use software, and free support from people who speak your protocol and understand your code: that’s the Opto 22 difference.