Learn best practices for storing both pre-processed and raw high-frequency vibration sensor data to maximize efficiency…

Learn best practices for storing both pre-processed and raw high-frequency vibration sensor data to maximize efficiency and accuracy for applications like predictive maintenance.

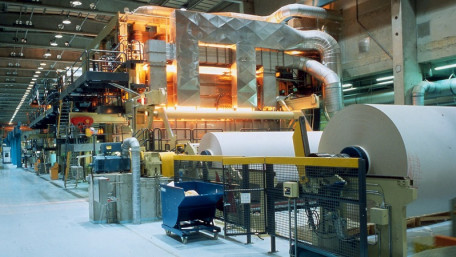

Innovative pulp and paper operators are turning advanced process control, automated testing, and quality control system…

Innovative pulp and paper operators are turning advanced process control, automated testing, and quality control system data into actionable business insights that improve operational efficiency all along the value chain.

Shifting from manual code backup processes to more modern, automated solutions can provide more benefits to…

Shifting from manual code backup processes to more modern, automated solutions can provide more benefits to manufacturers, far above simply the time saved compared to manual techniques.

Connected technology is the backbone of data transfer – data that can be used to predict failures and optimize…

Connected technology is the backbone of data transfer – data that can be used to predict failures and optimize workflows to enhance industrial operations.

This article reviews the challenges and opportunities when incorporating generative AI and Large Language Models in…

This article reviews the challenges and opportunities when incorporating generative AI and Large Language Models in industrial applications. It also examines how a Norwegian fishing and biotech company improved operational productivity and efficiency using generative AI.

Data has become the currency that enables operational excellence. Sensors are the key links, acting as the eyes and ears…

Data has become the currency that enables operational excellence. Sensors are the key links, acting as the eyes and ears of modern manufacturing units by providing real-time data on machine performance.

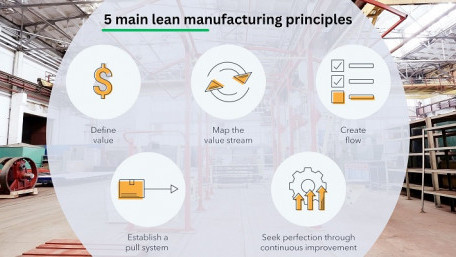

The Lean process uses a method of implementation focusing only on actions providing value to customers. The following…

The Lean process uses a method of implementation focusing only on actions providing value to customers. The following five steps break down the process into discrete modules when introducing efficiency to production.

To know if predictive maintenance is the right strategy, it might help to first recognize if it isn’t. Here are some…

To know if predictive maintenance is the right strategy, it might help to first recognize if it isn’t. Here are some indicators that your organization should improve before implementing predictive maintenance.

Memory for data is among the most pressing challenges to Industry 4.0. Given the evolving nature of Industry 4.0 and…

Memory for data is among the most pressing challenges to Industry 4.0. Given the evolving nature of Industry 4.0 and associated memory solutions, however, some memory-based trends are becoming apparent.

We'll run through the eight basic steps for implementing a predictive maintenance strategy in your business to improve…

We'll run through the eight basic steps for implementing a predictive maintenance strategy in your business to improve critical asset availability, reduced maintenance costs, and enhanced revenues over time.

Struggling to find the best ways to utilize real-time production data? This article reviews six steps to achieve better…

Struggling to find the best ways to utilize real-time production data? This article reviews six steps to achieve better manufacturing results.