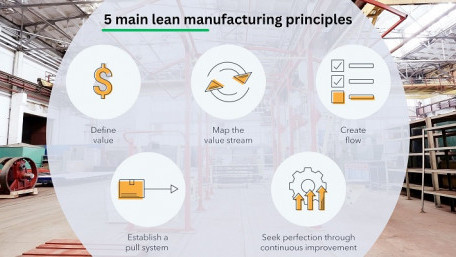

The Lean process uses a method of implementation focusing only on actions providing value to customers. The following…

The Lean process uses a method of implementation focusing only on actions providing value to customers. The following five steps break down the process into discrete modules when introducing efficiency to production.

To know if predictive maintenance is the right strategy, it might help to first recognize if it isn’t. Here are some…

To know if predictive maintenance is the right strategy, it might help to first recognize if it isn’t. Here are some indicators that your organization should improve before implementing predictive maintenance.

Memory for data is among the most pressing challenges to Industry 4.0. Given the evolving nature of Industry 4.0 and…

Memory for data is among the most pressing challenges to Industry 4.0. Given the evolving nature of Industry 4.0 and associated memory solutions, however, some memory-based trends are becoming apparent.

We'll run through the eight basic steps for implementing a predictive maintenance strategy in your business to improve…

We'll run through the eight basic steps for implementing a predictive maintenance strategy in your business to improve critical asset availability, reduced maintenance costs, and enhanced revenues over time.

Struggling to find the best ways to utilize real-time production data? This article reviews six steps to achieve better…

Struggling to find the best ways to utilize real-time production data? This article reviews six steps to achieve better manufacturing results.

Broken industrial machinery can cause unexpected downtime, production loss, and even injury. Let's look at some of the…

Broken industrial machinery can cause unexpected downtime, production loss, and even injury. Let's look at some of the most common issues and how to properly address them.

What are DIN Rail power solutions, and where do you need them in your facility?

What are DIN Rail power solutions, and where do you need them in your facility?