Sensor Data: Upgrading From Simple Inputs to Operational Analytics

To unlock the true value of sensor data in factory automation, it's essential to understand the differences in data utilization between the machine, network, and enterprise levels.

In recent years, the factory automation industry has witnessed remarkable advancements in sensor technology. From improved imaging technologies to more sensitive and highly integrated modules, modern sensors now offer unprecedented levels of insights into every corner of the manufacturing process.

Despite the proliferation of these sophisticated devices, there's still a palpable gap in harnessing the full potential of the data they generate.

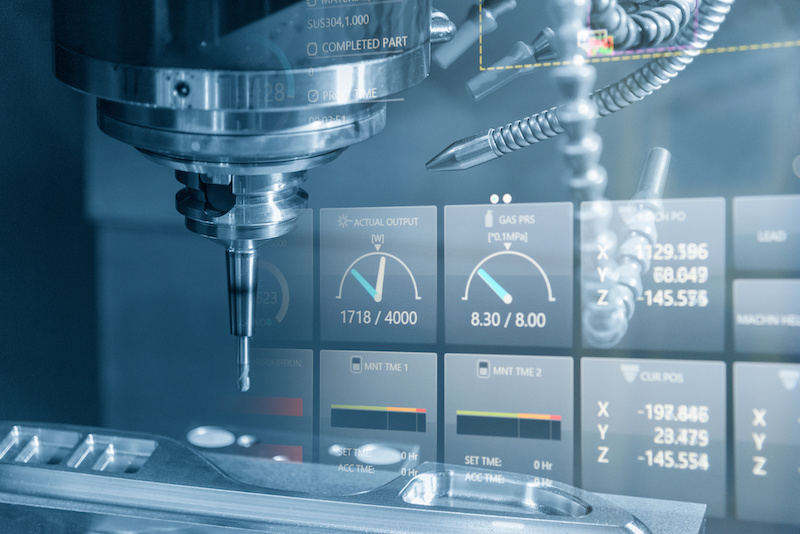

Figure 1. Modern factories are rife with data, but this data isn’t always fully utilized. Image used courtesy of Adobe Stock

This data underutilization starkly contrasts with the capabilities inherent in these technologies, suggesting that while we're adept at collecting data, we're not as proficient in analyzing it for actionable insights.

To unlock the true value of sensor data in factory automation, it's essential to understand data utilization on the machine, network, and enterprise levels. In this article, we’ll take a look at each of the three levels of data utilization, and how SICK helps customers navigate the complexities of data in modern factories.

Machine Level Data Utilization (Basic Sensing Products)

The first level of data utilization is the machine level: the process of collecting, analyzing, and acting upon data generated by machinery.

In the context of industrial automation and process control, basic sensing products such as 2D/3D cameras and encoders are integral. These devices convert physical phenomena into digital signals that machines can interpret, enabling precise control over day-to-day operations. In a manufacturing line, 2D/3D cameras can capture detailed images of objects, allowing for quality control, object detection, and the guidance of robotic arms. Encoders, on the other hand, provide accurate position and speed feedback for motors and other moving components, facilitating precise motion control.

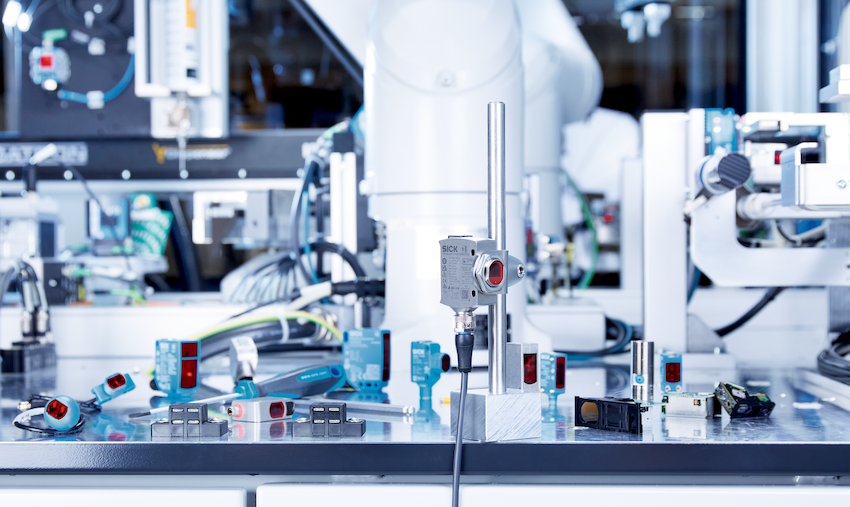

Figure 2. Sensors can provide a plethora of data concerning machinery operation. Image used courtesy of Adobe Stock

An encoder, for example, may signal a motor to stop if it detects that a conveyor belt has reached its intended position, or a camera might identify a defective product on a production line, triggering its removal. These tasks, essential for operational efficiency and product quality, rely on the direct, straightforward use of data from basic sensing products.

However, this traditional approach to utilizing machine-level data—focusing solely on immediate operational tasks—overlooks the rich potential of these inputs for data analytics. By concentrating only on real-time control and immediate responses, industries miss out on the opportunity to extract valuable insights that could lead to process optimization, predictive maintenance, and enhanced decision-making.

Analyzing trends from encoder data over time could reveal patterns indicating the early stages of wear and tear in machinery, allowing for preventive maintenance before a costly failure occurs. Similarly, historical data from cameras can be used to improve object recognition algorithms, leading to better product quality and reduced waste.

Integrating machine-level data with advanced analytics and artificial intelligence could transform operational tasks from reactive to proactive, paving the way for smarter, more autonomous systems.

Connectivity/Network Level Data Utilization

The next level for data utilization is the connectivity/network level, the process of collecting, transmitting, analyzing, and leveraging data generated from devices connected across a network. The idea is to use the data flowing through these networks to improve efficiency, make informed decisions, and enable automated or semi-automated operational tasks.

At the core of this integration lies network connectivity hardware, particularly Sensor Integration Gateway (SIG) and Sensor Integration Machine (SIM) devices.

SIGs are advanced interfacing devices designed to streamline the integration of IO-Link and other sensors into broader control and data processing systems, such as programmable logic controllers (PLCs) and enterprise-level systems. By serving as an IO-Link master, SIGs facilitate the direct communication and management of multiple sensor devices, allowing for the aggregation, evaluation, and transmission of sensor data across various fieldbus protocols.

SIM devices, on the other hand, are engineered to collect data from a wide array of sensors. They can then process, interpret, and integrate this data into a coherent format for use by software applications and cloud-based platforms. With built-in computing capabilities and support for various communication protocols, these devices act as data aggregators, processors, and communicators, sending processed information to other systems.

Figure 3. Modern factories are highly interconnected, making network-level data utilization extremely valuable. Image used courtesy of Adobe Stock

A key hurdle in creating a fully integrated system is the heterogeneity of sensor data and communication protocols, where different devices operate on distinct standards. Additionally, the sheer volume of data generated by sensors poses significant challenges in terms of data processing, analysis, and storage, requiring substantial computational resources and sophisticated data management strategies.

Solutions like SIG and SIM devices solve these issues by bridging the gap between diverse technological ecosystems and streamlining the data flow from the sensor level to higher-order data processing and analysis systems. By providing a means of aggregating disparate data formats and communication protocols, these devices ensure that data from various sources can be integrated and interpreted within a unified framework. Additionally, the advanced computing capabilities of SIM devices, coupled with the versatile communication options offered by SIGs, enable real-time processing and analysis of sensor data on the factory floor.

Enterprise/Analytics Level Data Utilization

The final level of data utilization is the enterprise/analytics level, the strategic application of data analysis and interpretation across an entire organization to inform decision-making, optimize operations, and drive business growth.

One of the prime examples of machine data utilization is predictive maintenance. Sensors embedded in machinery can monitor parameters such as temperature, vibration, and acoustics, providing a real-time health report of the equipment. This data, when processed through analytics software, can predict potential failures before they occur, allowing for timely maintenance interventions, reducing downtime, and extending the lifespan of the equipment.

However, transitioning to a data-driven approach at the enterprise level is complicated by the integration of disparate systems and sensors into a cohesive analytics platform and data heterogeneity, with data coming in various formats and from different sources, challenging aggregation and analysis. Additionally, the technical skillset required to manage and interpret complex data analytics is often in short supply, demanding investment in training and development.

Overcoming these barriers requires a strategic approach, including top-down support for cultural change, investment in scalable and secure technological solutions, and a focus on upskilling the workforce to thrive in a data-driven environment. With these elements in place, enterprises can unlock the full potential of their data, leading to operational excellence and sustained competitive advantage.

SICK Products Unlock Valued Data

To unlock the true value of sensor data in factory automation, a deep understanding of each level of data utilization and actual practice in real-world application is necessary. SICK has a comprehensive lineup of products that aid in leveraging each of the three levels of data utilization.

Figure 4. SICK’s W10 photoelectric proximity sensor is simple to install and use, and adaptable to a variety of applications. Image used courtesy of SICK

- Machine Level: SICK’s W10 is a groundbreaking touchscreen photoelectric proximity sensor that uses intelligent onboard algorithms to fulfill the roles of hundreds of different sensors traditionally used in industrial automation. SICK also provides an assortment of 2D/3D cameras, like the Lector85x code reader, and encoders, like the AFS/AFM60, for greater machine-level visibility.

- Connectivity/Network Level: SICK offers SIG and SIM devices like the SIG200 and SIM4x00, both of which are designed to pair with machine-level sensors. These devices help make sure that sensor data is accessible and reliable across an entire network.

- Enterprise/Analytics Level: SICK ties all three levels together with advanced analytics solutions that allow factory operators to acquire, visualize, and monitor their systems to improve efficiency. These include Field Analytics, a highly scalable I4.0 manufacturing data intelligence software, and Logistics Diagnostic Analytics, which provides comprehensive, real-time performance and health monitoring of automated identification systems

As factories become more intelligent and data becomes more abundant, a holistic approach to sensor data analytics will be a key enabler of the factory of the future. With a slew of comprehensive product offerings for the factory, SICK is committed to ensuring that this future is within reach.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin