Improving Automated Test Equipment Product Life and Board Density

Join OMRON's upcoming webinar this July to understand more on the latest signal relay and blade pin technologies to enable the advancement of automated test equipment and the next generation of semiconductors.

As semiconductors and consumer electronics become more sophisticated and complex over

time, the need to test these devices does as well. The Automated Test Equipment industry goes

to great lengths to ensure test machines and boards can last in the field over the course of

many years for a variety of devices under test. A major factor for keeping test equipment in the

field over time is designing in components that guarantee specifications over millions of cycles.

Additionally, with the latest trend in semiconductor test demanding more channels at higher

currents to enable the advancement of AI chipsets, board density continues to be a top priority.

Designers are looking for available options to help them downsize their boards for increasing

test capacity and capability. For over a decade OMRON has been a leader in components for

the Automated Test Equipment industry, supplying MOSFET relays and EFC Blade Pins to

improve overall product life and board density.

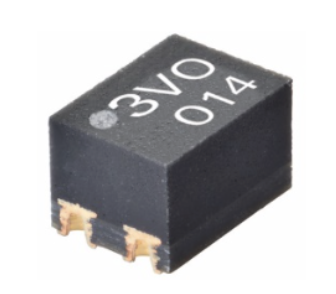

MOSFET Relays

Traditional electromechanical and reed relays utilize physical contacts which can increase

contact resistance when operated over millions of cycles. This leads to relay and test failures

and increases the amount of rework and stoppage of testing. By utilizing MOSFET relays from

OMRON, tests can be conducted with stable ON resistance over the life of the product.

OMRON's MOSFET Relays are LED operated with no physical moving contacts inside, which

allows them to maintain a stable ON resistance for millions of cycles increasing the life of a

product and keeping testing active.

OMRON's MOSFET relays also come in a variety of small, through hole and surface mount

packages down to 2.0 x 1.45 x 1.65mm to drastically save board space. With LED operation,

MOSFET relays provide impressive performance without needing the space typically taken by

internal contacts and coils. OMRON also offers non-leaded terminal package types to further

reduce the relay's total footprint. Selecting a MOSFET relay from OMRON can help provide

more real estate on your board for your next test.

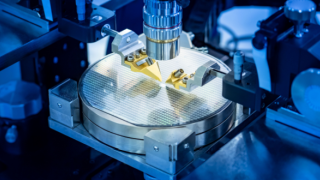

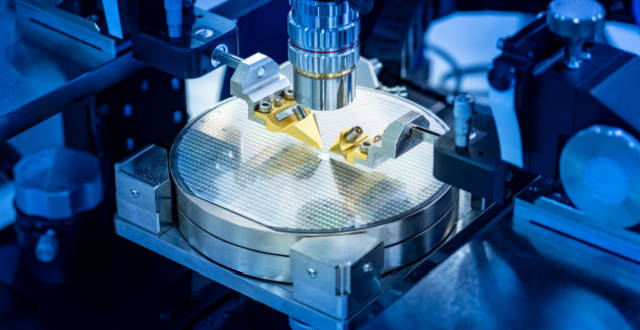

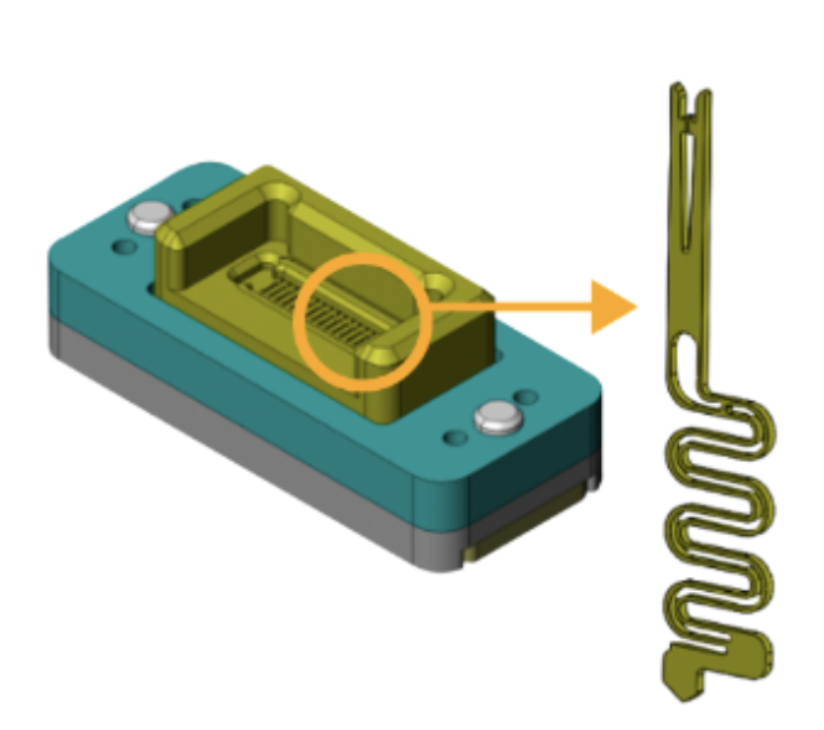

EFC Blade Pins

Test pins commonly used in inspection equipment can provide inconsistent test reliability and

contact resistance which causes an increase in rework and downtime for testing. OMRON Blade

Pins are manufactured by utilizing its proprietary electro formed component (EFC) process

technology. With EFC, OMRON is able to produce custom pin and socket designs to provide

greater durability, reliability, and performance for a range of applications. EFC Blade pins allow

for inspection equipment to remain operational, testing more devices being manufactured, and

reducing downtime.

Webinar Summary:

Join OMRON's upcoming webinar this July to understand more on the latest signal relay and

blade pin technologies to enable the advancement of automated test equipment and the next

generation of semiconductors. We will elaborate on the current needs of the ATE market and go

in depth on the latest solutions that OMRON is releasing to meet them. Discover how these

relays and blade pins can help provide longer product life, save on board space, and improve

test reliability in your next test design. In this webinar you will learn:

- Utilize LED operated MOSFET Relays with stable ON Resistance for millions of cycles

- Incorporate a variety of small MOSFET Relay package sizes to help save board space

and increase density - Keep device inspection equipment running longer with high durability EFC Blade Pins

Webinar Title: Improving Automated Test Equipment Product Life and Board Density

Date: Thursday, July 18th

Time: 11:00am CST / 12:00am EST / 9:00am PST

Presenter: Evan Kuhn, Business Development Manager, OMRON Electronic Components

Evan Kuhn attended Northern Illinois University, where he obtained his Bachelor of Science in Electrical Engineering Technology. Starting as a Product Marketing Intern with Omron, Evan began his career in Inside Sales after school and then became the Territory Manager for the Pacific Northwest. Currently residing in Seattle, he is now Omron’s Business Development Manager for the Automated Test Equipment and AI Integration Industries.

Connect with OMRON Electronic Components on social media:

LinkedIn: https://www.linkedin.com/company/omron-electronic-components-americas

YouTube: https://www.youtube.com/c/OmronElectronicComponentsAmericas

Twitter: https://twitter.com/OmronComponents

Instagram: @omron_dms

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin