Where No-Code PLCs Fit in Automation (And Where They Don’t)

Learn new ways to monitor and control I/O endpoints through lightweight, no-code PLCs that make logic accessible and uncomplicated.

White Paper Overview

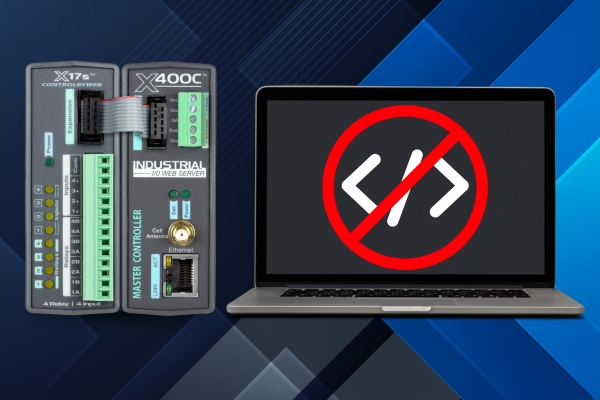

Traditional programmable logic controllers (PLCs) are essential in factory automation, handling complex logical instructions. They’re also favored by engineers who default to familiar and reliable controllers. But technology is evolving rapidly, and new ways of monitoring and control are emerging. Enter no-code PLCs—a simpler alternative. These small PLCs are faster and easier to implement while being more cost-effective. They require no coding and can handle network settings, data logging, and conditional logic. While larger PLCs remain crucial for complex applications, no-code PLCs excel in classic IIoT scenarios, such as remote monitoring and simple processes.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin