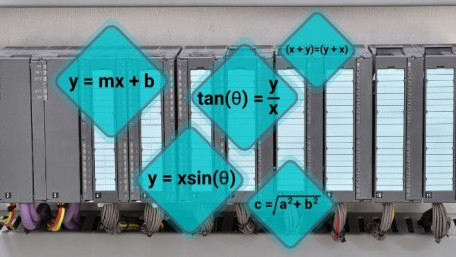

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean, well-organized, and easy-to-use code that…

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean, well-organized, and easy-to-use code that allows you and other users to troubleshoot your programs.

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and…

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and Automation Direct Productivity Suite.

Programmable Logic Control (PLC) systems are the core of most industrial control systems that drive modern manufacturing.…

Programmable Logic Control (PLC) systems are the core of most industrial control systems that drive modern manufacturing. In our Control.com video tutorials, we will share information, experience, and tips for working with PLCs—from the hardware, to the wiring, to the programming logic of inputs, outputs, and communication processes.

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement…

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational insights about machine performance statistics.

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common…

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common instruction is the one-shot, capable of harnessing the incredible processing speeds in a CPU.

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and…

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and unavailable, and the lack of an upgrade plan can turn a simple failure into a catastrophe.

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the…

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the world of control systems. Learn how the hardware platforms have evolved into the familiar modern configurations.

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as…

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as retentive timers and define the inputs and outputs required to properly use them.

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission.…

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission. But when we say ‘easy’, how easy can it really be to commission robotic tools?

Power supplies tend to get a reputation as one of the most important power considerations of a DC control circuit - but…

Power supplies tend to get a reputation as one of the most important power considerations of a DC control circuit - but we can’t ignore other key players: power filters, converters, and backup power modules.

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal?…

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal? Some systems use simple open/close valves, but others require far more precision.

Allen Bradley’s Data Highway Plus (DH+) networking ability is still found commonly in interfaces with legacy equipment.…

Allen Bradley’s Data Highway Plus (DH+) networking ability is still found commonly in interfaces with legacy equipment. Understanding this network structure can bridge the gap between old and new systems.

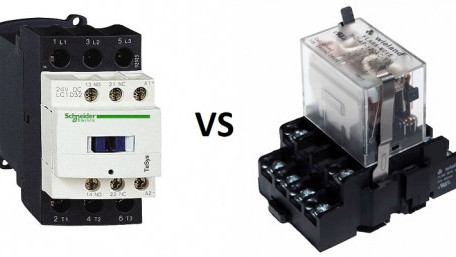

Although the are similarities in operating theory, relays and contactors are used in industrial circuits for different…

Although the are similarities in operating theory, relays and contactors are used in industrial circuits for different specific applications, and should not be used interchangeably.

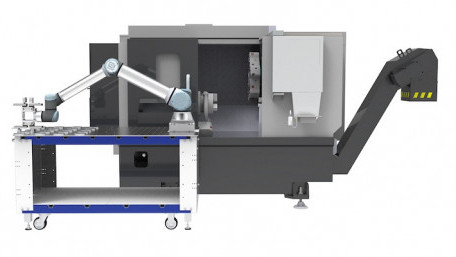

Our own Control Automation engineering staff had the opportunity to visit VersaBuilt, a CNC robotic integration shop…

Our own Control Automation engineering staff had the opportunity to visit VersaBuilt, a CNC robotic integration shop offering an application system from the Universal Robots UR+ series.

Two common methods exist for driving induction motors with VFDs - linear scalar control, which is often labeled as V/f,…

Two common methods exist for driving induction motors with VFDs - linear scalar control, which is often labeled as V/f, and vector, or field-oriented control, which can be a bit more complex to understand.

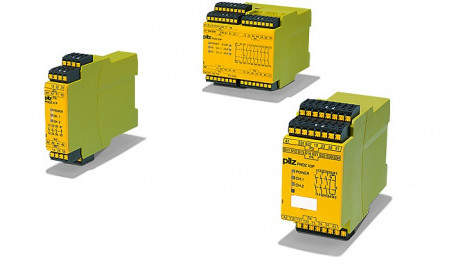

Redundancy and safety are often seen together in industrial safety systems. Safety relays monitor emergency devices to…

Redundancy and safety are often seen together in industrial safety systems. Safety relays monitor emergency devices to switch contacts based on status - but what makes them different from normal relays?

Advanced features such as programmable limits, diagnostics, and remote configuration are available with IO-Link devices.…

Advanced features such as programmable limits, diagnostics, and remote configuration are available with IO-Link devices. Learn how to connect an example IO-Link block into an actual PLC project.

Linear position sensors are used in electrical and fluid-actuated motion devices. They allow extremely precise position,…

Linear position sensors are used in electrical and fluid-actuated motion devices. They allow extremely precise position, velocity, and acceleration control, and provide feedback to ensure product quality and tolerance compliance.

With the increasing appearance of “web-based” HMIs, we investigate these devices, learn how they differ from the…

With the increasing appearance of “web-based” HMIs, we investigate these devices, learn how they differ from the graphical HMIs, and see implications for our modern control system architecture.

AC motors are common throughout industry - easily controlled by VFDs and without the maintenance that comes with DC…

AC motors are common throughout industry - easily controlled by VFDs and without the maintenance that comes with DC brushes. So then, why are DC motors still used in certain applications?