Siemens Addresses Testing Troubles in Harsh Environments with New Data Acquisition System

Siemens recently expanded their Simcenter portfolio to include rugged test equipment, including the SCADAS RS

The ruggedized hardware of Siemens's latest SCADAS RS is designed to collect data in dusty or damp environments or spaces with a lot of vibration. This makes the component geared towards mobile environments, such as collecting data from construction equipment, passenger vehicles, railroads, and more.

Video used courtesy of Siemens

In particular, the transportation, mining, agricultural, and construction industries may benefit from this system. Anyone can put a few rubber bumpers on a piece of equipment and call it “ruggedized.” Siemens is promising to do more by getting their systems tested against the Ingress Protection (IP) ratings.

The SCADAS RS

The SCADAS RS can be rated to IP66 (dust-tight, water jet tight) or IP67 (temporary water immersion). This is crucial for most all construction equipment.

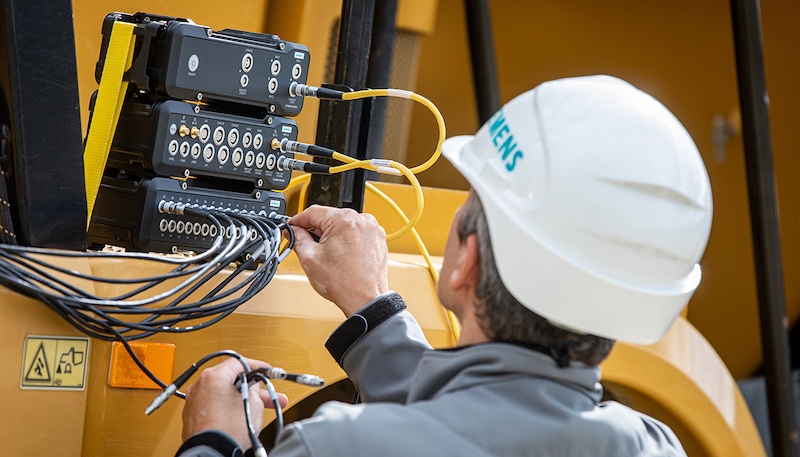

The Siemens SCADAS RS collecting data on this piece of construction equipment. Image courtesy of Siemens

Suppose there was a need to collect data from a front-end loader, such as the one pictured above during a large road-paving project. While the front end loader is scraping along in one direction, a water truck used to reduce dust during construction sprays the surface, traveling in the other direction. The SCADAS RS aims to minimize the concern. The device gets sprayed and, in turn, is not damaged.

Equipped for Vibration in Industrial Environments

The SCADAS RS can also be applied to vibrating environments, rated up to 100 g of shock and 10 grms of vibration. This makes them applicable for mobile environments and industrial environments prone to vibration, such as rock crushing operations, vibratory sorting, sawmills, and any other place that handles raw materials.

When all raw materials are not created equally, they tend to generate multiple unpredictable vibration signatures. This can be hard to dampen.

Suppose the data acquisition system is not equipped for this random vibration. In that case, it will quickly vibrate itself apart, either by loosening components or connectors or by loosening the seals that prevent dust and moisture from entering the case. With the SCADAS RS, this is not an issue due to its vibration-resistant design.

More Accurate Testing Capabilities

Aside from the rugged design, the interfacing and data are designed to be extremely portable. Devices can be monitored and accessed from laptops, tablets, or smartphones with a graphical user interface (GUI).

Hidden in this image is a SCADAS RS module, covered in dirt and still functioning. Image courtesy of Siemens

This means data files up to 1000 channels, synchronized to 1 microsecond, are available for browsing and analysis from virtually anywhere. The data is available on site or back at the office, without manually transferring a USB stick or SD card or having to email large files. This may be especially useful for troubleshooting problems, where an engineer or technician can view the data and make changes to the equipment. This can be done while another engineer, technician, or specialist can view the same data simultaneously.

The Siemens SCADAS RS module aims to make rolling stock and mobile testing reliable and trouble-free. This system may also benefit stationary and hostile environments that make for difficult testing environments.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin