Yokowo Aims to Improve Data Transmission Speed with Latest Fiber Optic Transceiver

Thermal imaging can help solve predictive maintenance problems. Yokowo recently launched an optical transceiver to help this industrial automation process.

Yokowo manufactures automotive communication devices, electronic connectors, including optical connectors, and advanced medical equipment. Yokowo started its journey in the 1950s, specializing in automotive antennas then moving into sporting equipment by the end of the decade. By the 1980s, Yokowo moved into producing spring-loaded contact probes, which are widely used in the production testing industry.

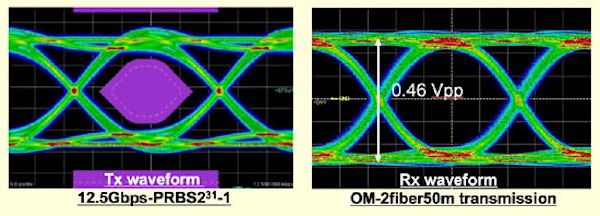

Thermal waveforms from the industrial vision systems. Image used courtesy of Yokowo

In the mid-1980s, Yokowo started producing personal communication antennas and microwave technology. Over the past three decades, Yokowo has grown and managed to position itself as a leader in communication antennas and electronic connectors. Yokowo recently released a fiber optic transceiver and connector that will play an important role in connecting high-speed industrial vision systems.

Fiber Optic Transceiver and Connectors

Data transfer outside the component is becoming a very competitive field. Transferring data within a component is easy because the manufacturer can control the size and material used to transfer that data. Once the user wants to transmit data to another device, the manufacturer is at the mercy of the available connectors on the market for the speed and quality of the signal.

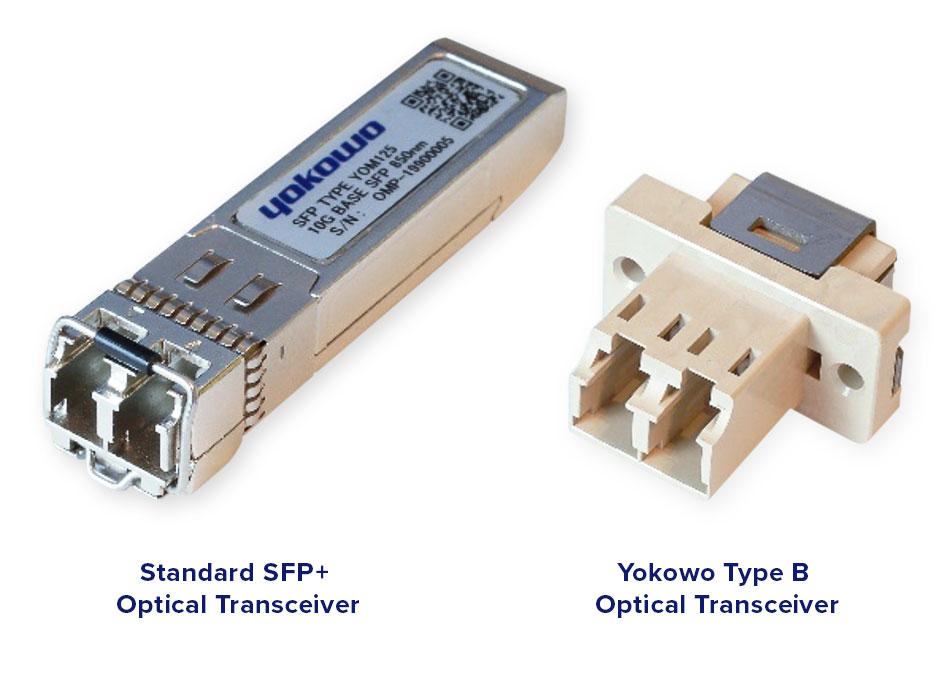

Yokowo optical transceiver. Image used courtesy of Yokowo

Yokowo is working to improve the speed of transmission and reduce the size of the overall connector. By using fiber optics, Yokowo has found a way to provide speeds up to 50 Gbps (12.5 Gbps if using power transmission), and at 1/10 the size of a typical fiber optic transceiver. This means faster data transfers in smaller packages.

When designing machine automation, space is always a concern. Putting vision systems in tight spaces allows for complex vision inspections, reducing multiple stations with expensive tooling or robotics. Transferring data quicker means high-quality images faster. Faster inspections mean more throughput through the machine, which means more product at the end of the line.

Other Industrial Offerings From Yokowo

Yokowo also offers a line of testing tools for electrical equipment and components. While the automotive world has not been a stranger to electrical components for some time now, they are venturing into new territory with electric vehicles. Battery-operated vehicles need a whole new kind of testing. The batteries need to be tested for proper voltage and charge parameters, and It’s important when testing components in automation that the testing equipment doesn’t damage the tested component. The battery housing needs to be tested for electrical discharge capacitance.

Yokowo produces connectors that can be used in automation, like the KN series for HDMI, USB standard, USB micro, and USB type C. The KN series is designed for automation and claims not to damage the product.

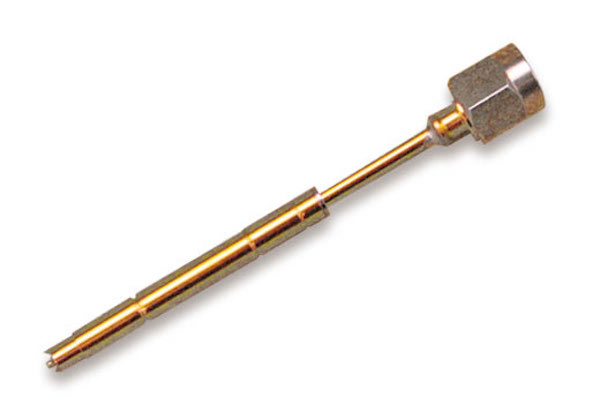

A coaxial probe. Image used courtesy of Yokowo

When testing components in an automated setting, it’s important to have a solid connection without locking the connector or using a human to remove the connector. Utilizing spring-loaded contact pins has been used for many years. Yokowo has produced a line of contact pins that make a solid connection to very small connectors on circuit boards or any other electrical device.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin