ABB and Amazon Web Services (AWS) Partner to Streamline Mining Operations

How could this potentially help engineers streamline OT data?

ABB has entered a new partnership with Amazon Web Services (AWS) and heavy-duty electric vehicle (EV) drivetrain developer MEDATech to accelerate the adoption of new and sustainable technologies in mining. The companies are specifically creating solutions to integrate all-electric operations in a digital fashion to aid meet industry goals on net-zero emissions.

ABB and AWS confirmed they will collect and analyze the vehicle data during truck testing, to hopefully implement the system in a real mining environment.

ABB and AWS

As part of the new partnership, the ABB Ability Operations Management System (OMS) has been integrated within MEDATech’s cloud data collection system, using the AWS cloud infrastructure.

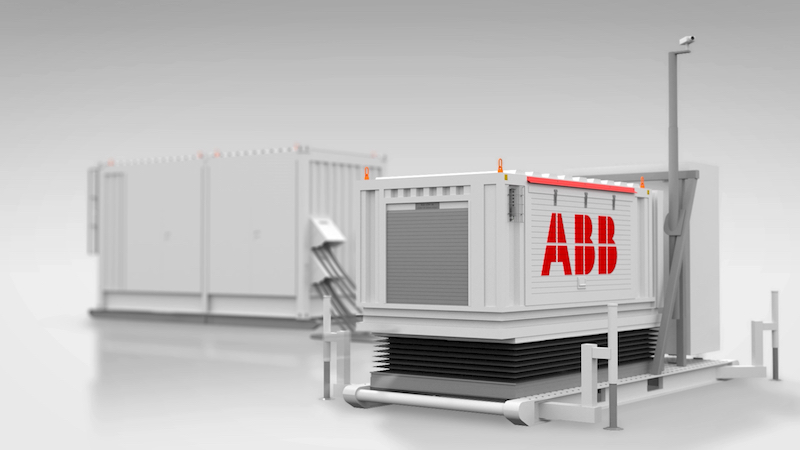

The ABB Ability eMine FastCharge machine in action. Image used courtesy of ABB

In terms of hardware, the system deployed in the pilot phase utilizes ABB’s eMine FastCharge, a fully automated charging system. The ABB Ability eMine family includes several electrification technologies designed to enable the deployment of all-electric mine infrastructure from mine to port.

eMine solutions can be deployed to electrify mining equipment, including hoisting, grinding, hauling, as well as material handling, and the entire process area.

During the new trials, telemetry data, such as battery state and speed of charge, was transmitted from MEDATech’s 100 percent electric haul truck, which was paired with ABB’s eMine FastCharge. Data integrity and security were performed during operations using AWS’s IoT services.

“Together, ABB, MEDATech, and AWS have demonstrated a fully integrated solution for mining operators to combine data from electric vehicles and operations to maximize their efficiency and contribute to their sustainability goals,” said Flemming Kongsberg, Director of Global ISV Alliances at AWS.

The ABB Ability eMine FastCharge. Image used courtesy of ABB

The data thus obtained was then utilized to perform real-time production optimization for test purposes during the MINExpo event held last September in Las Vegas.

“Through this collaboration, we are excited to help deliver this solution to our customers worldwide, providing flexibility, scalability, and security in the cloud,” Kongsberg added.

Improving Operational Efficiencies

The digital integration of electrical equipment for industrial operations is growingly relevant for operational efficiencies, particularly regarding optimized scheduling and planning.

According to ABB, battery EVs (BEVs) and their charging infrastructure present both a challenge and an opportunity as the industry increasingly allocates resources towards decarbonization and reduces resources and energy consumption. The collaborative and interoperable approach adopted by ABB, AWS, and MEDATech should now tap into these opportunities by removing management and investment responsibilities commonly associated with on-premises infrastructure from the customer.

“We can work together to achieve practical results that support mining operators to meet industry and sustainability commitments,” said Max Luedtke, ABB’s Global Head of Mining, Process Industries.

Moving forward, and having proven the feasibility of this pilot project with the MEDATech battery electric vehicle, ABB said they will now focus on driving digital interoperability further.

The electric mining haul truck Western Star 4900XD. Image used courtesy of Western Star

“It is essential to access and analyze electrical equipment data via an open, standardized platform safely and reliably,” Luedtke added.

This goal will be achieved by adapting the new system to further mining assets, both mobile and stationary, as well as addressing their dependencies to optimize the overall process efficiency. What do you think about this new partnership and its effects on the automation industry? Let us know in the comments below.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin