ABB Introduces New Motor Solutions at EASA Convention

ABB showcased its latest innovative motor solutions at the EASA Convention in Saint Louis, Missouri on June 26-28. The motors are designed to operate in harsh industrial environments, with different options available to fit customers' changing needs.

ABB attended the EASA Convention in Saint Louis, Missouri on June 26-28, where they explained the importance of choosing the correct motor, connected customers with industry experts, and showed off their lineup of motor solutions.

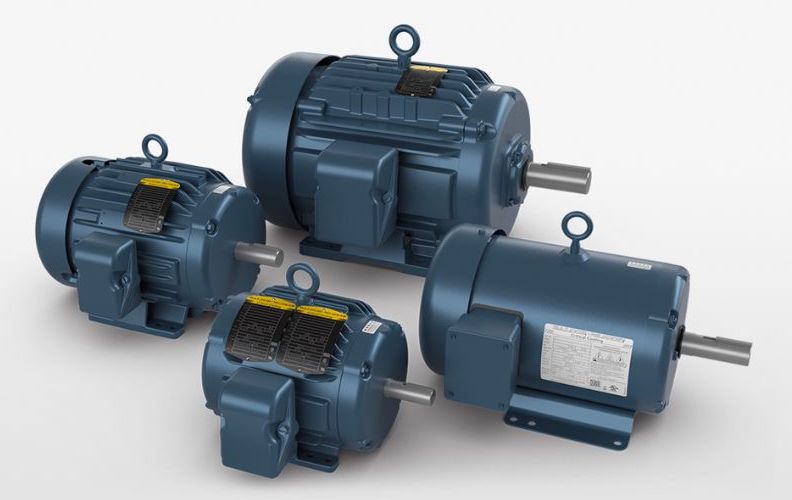

ABB’s 661XL motors are part of the Baldor-Reliance® motor lineup capable of handling harsh environments and easily fitted with VFDs. Image used courtesy of ABB

Baldor-Reliance® and ABB Motors

ABB’s Baldor-Reliance® motors are designed for use in harsh environments. They are built with ingress protection to keep bearings and motor components safe from external contaminants such as dust. At least 90% of all the Baldor-Reliance® motors meet the Buy American Act, and therefore can be expected to meet most customers' power needs.

The motors are specifically designed to handle harsh environments including:

-

petrochemical plants

-

mines

-

foundries

-

pulp and paper plants

-

waste management facilities

-

rock crushers

-

chemical plants.

The motors can be fitted with variable frequency drives (VFDs) in order to fit customers specific needs. VFDs help with wear reduction and help to reduce power consumption for certain applications. VFDs are also useful in reducing equipment failure due to excessive power or motor speed, further increasing motor lifespan.

ABB’s Critical Cooling motors, part of ABB’s Baldor-Reliance® motor lineup, come with a lifetime bearing guarantee. Image used courtesy of ABB

The Baldor-Reliance® motors are capable of being used in versatile applications with the use of new technology. They are capable of variable torque, constant torque, and constant power with the use of an interactive display. As part of their Baldor-Reliance® motor showcase, ABB featured an interactive display with their latest Critical Cooling motors.

Also presented was ABB's new ECP5000 motors for heavy duty applications at the convention. The motor is designed for applications that require more horsepower and features a power dense construction. The motors are designed and built in the United States, with an eye specifically toward fitting into the North American market.

ABB motors are designed with expectations of several defining safety principles. For example, the motors are designed with increased safety in mind with their rugged lifting provisions and oversized conduit boxes. The connection points are also safer as a result of clamp-type grounding lugs and permanently labeled color leads for power connection. The motors even fit into division 2 standards for hazardous locations.

The ABB Ability™ Smart Sensor provides touch-free condition monitoring and is compatible with ABB motors to ensure optimal performance and minimal downtime. Image used courtesy of ABB

Digital Solutions and Features

ABB motors are compatible with ABB Ability™ Smart Sensor. The sensor is capable of providing customers with touch-free condition monitoring. In addition, the ABB Ability™ Smart Sensor provides rapid response, lifecycle management, operational efficiency, and performance improvement. All of these work together to produce a system that ABB hopes will optimize performance, minimize downtime, and extend the life of equipment. All severe duty motors use cast iron components for durability to ensure that the motor is durable enough for tough conditions.

Beyond the construction of the motor itself comes superior performance, according to ABB. This entails motor vibration limits, lower operating temperatures, and the ability to handle voltage spikes. The heavy duty motors hope to provide customers with performance improvements, extended equipment life, and downtime minimization.

Leading Global Technology

ABB is a leading technology company that looks to provide a sustainable future. They have over 105,000 employees in over 100 countries. ABB continues to look for more efficiency and performance by connecting software to its electrification, robotics, automation, and motion.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin