ABB Releases Noninvasive Temperature Sensor With SIL2 Certification

ABB has launched a NINVA SIL2-certified noninvasive temperature sensor for safer and more precise measurements in the chemical and oil and gas industries.

ABB now offers a SIL2-certified, CapEx-saving temperature sensor for noninvasive temperature measurement in industrial environments. This latest sensor is built upon ABB’s existing NINVA TSP341-N sensor to provide a more cost-effective, safety-enhancing experience for engineers working with applications in the chemical and oil and gas industries.

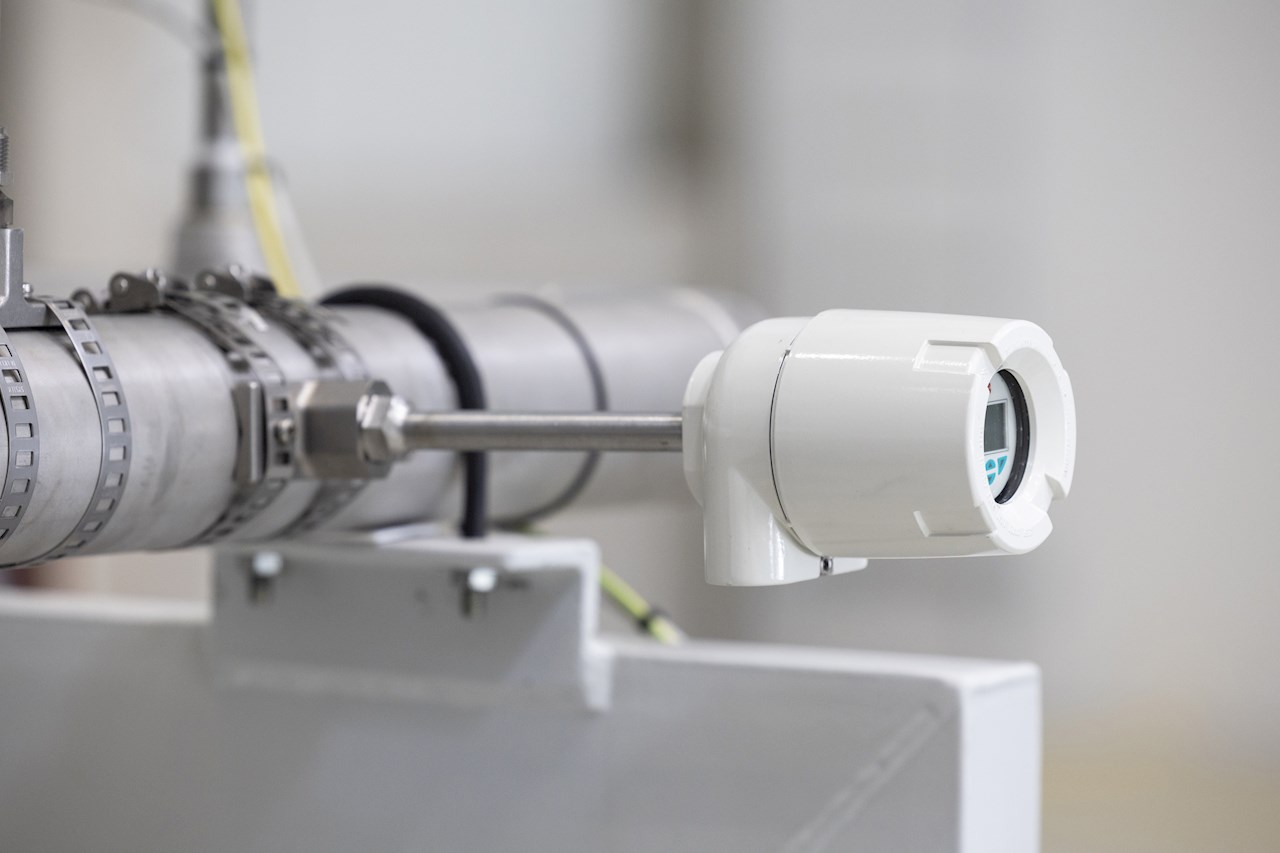

ABB now offers its NINVA TSP341-N sensor with a SIL2 certification. Image used courtesy of ABB

Why Are Temperature Sensors Important?

Precise temperature control is critical for safeguarding the environment because it reduces emissions by guaranteeing complete combustion (while mitigating the release of harmful gasses) and preventing spillage through early identification of irregular conditions. Temperature sensors offer real-time data transmission to engineers, allowing them to make informed decisions, automate process changes, and initiate safety processes to prevent mishaps.

Temperature stability is essential for products in the chemical sector since variations might affect the composition and quality of the product. Temperature sensors guarantee that items satisfy specifications and adhere to regulatory norms, averting legal difficulties. They also optimize energy usage, lowering expenses while increasing efficiency. To prevent energy waste from overheating or underheating, temperature sensors keep equipment at the appropriate working temperature in an oil and gas facility.

Appropriate working temperatures are also critical for maintaining worker safety, as any extreme temperature variations could lead to dangerous situations such as explosions, fires, and unwanted equipment malfunctions. Any of these scenarios are hazardous to workers and cause unwanted downtime. Temperature sensors are vital for detecting temperature variations and alerting engineers when immediate intervention is needed.

ABB’s SIL2-certified NINVA TSP341-N sensor is noninvasive and remote mount configurable. Image used courtesy of ABB

Noninvasive Temperature Measurement

Conventionally, thermowells have been employed to protect temperature sensors (used in industrial applications) against damage from corrosion, immoderate pressure, and material velocity. A drawback to thermowells is the reduced response time incurred from the added layer between the substance and the sensor. Although tapered or stepped thermowells can counteract this, including this equipment adds to the cost of the complete temperature measurement system.

Compared to a thermowell, the updated version of ABB’s NINVA TSP341-N sensor is SIL2-certified and measures temperature in a noninvasive manner, taking readings from the piping surface to extrapolate the process temperature. To meet the requirements for SIL2 level certification, self-testing should be available for hardware components, along with shorter sensor maintenance intervals, stringent development standards, and properly documented software.

The NINVA TSP341-N sensor uses a double-sensor architecture, utilizing a reference and contact sensor to help collect error-free temperature measurements. Image used courtesy of ABB

The SIL2-Certified NINVA TSP341-N

The enhanced NINVA TSP341-N sensor uses a double sensor architecture (comprised of a contact and reference sensor) alongside a thermal model to correct any errors typically encountered with surface sensors. Since a sensor does not need to penetrate through pipework to access the process, time and money are saved on initial sensor installation. According to ABB, customers can benefit from 75% CapEx savings and low cost of ownership in the long term.

Customers can take steam and energy measurements with high-temperature options up to 550 °C. The novel remote mounting option provides higher vibration resistance, and extractable insets provide more streamlined maintenance and calibration. The NINVA TSP341-N sensor can accommodate all pipe diameters (40 mm to 2500 mm using adjustable clamp collars and under 40 mm with a specially-made design).

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin