ABB Robotics Introduces Partner System To Speed Project Development

ABB recently announced the deployment of the partner ecosystem which offers packaged ABB and B&R automation solutions to help reduce integration and design time.

More companies are taking a leap of faith and jumping into robotic solutions, but this decision doesn’t come lightly. Industrial robots require properly trained personnel to maintain the robot.

Equipment manufacturers often love to throw robots at problems, but it is up to the integrator to get that robot functioning the way the mechanical designer intended, along with integrating all the other systems. This can be a daunting task and typically requires a dedicated resource just for the robot application.

ABB Robotics’ New Partner Ecosystem

Designing a robot solution takes quite a bit of technical knowledge. An improperly designed gripper could cost weeks of re-design and schedule slip. It is for these reasons that ABB is introducing the new ‘Partner Ecosystem’, which claims to take the guesswork out of robotic solutions.

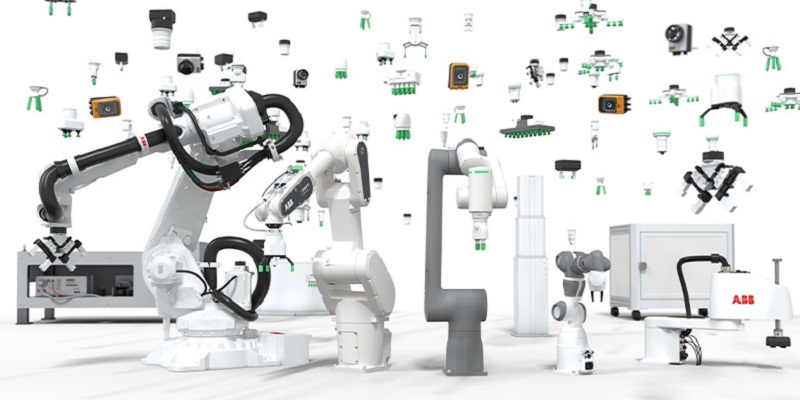

Example robot material handling application. Image used courtesy of ABB

ABB and B&R Partner for Faster Deployment

ABB is a global supplier of industrial robots and cobots, along with an extensive high-voltage product line. ABB also partners with B&R Automation, a company with product lines spanning across industrial PLCs, IPCs, and vision systems. The partnering team has launched a program that assists equipment manufacturers and end users to develop robot systems to solve automation problems.

The partner program doesn’t just help select the correct robot for an application, but also what style of gripper to use, or if a vision-guided solution is required. The program can suggest products from ABB or B&R’s product lines or from any other partnered company. The products suggested are fully integrated into ABB's portfolio, a move that reduces integration and commissioning time by reducing the need to collaborate with many suppliers.

Right now, the program only supports hardware packages such as robots, grippers, tables, and feeders from major manufacturers including SCHUNK, Zimmer, and Schmalz, but soon ABB will also pre-configured software packages, reducing the integration time even further. The hope for this program is to reduce the stress or time required to design, implement, and commission a robotic solution.

Programming a robot is only a small part of the design phase. Image used courtesy of ABB

Applications of a Partner Ecosystem

Robotic systems can be very complex to design and integrate. Programming a robot takes the actual coding skills as well as mechanical skills. Robot programs consist of text that translates into robot movements, program control, input or output, and file management commands. Teaching the robot requires a keen eye and an understanding of cartesian coordinate systems. Designing a robotic system can require complex math and engineering principles. These technical skills are not always available at small independent factories, so many companies shy away from robot solutions.

A wide arrays of robots, end effectors, and applications are all critical parts of a good system. Image courtesy of ABB

Machine integrators and machine builders are sometimes at the mercy of the customer when it comes to designing equipment. The customer’s maintenance department may not have the technical skills required to maintain equipment with robots, or the proposed solution is too complex to integrate in a timely manner.

With the partner ecosystem, ABB can reduce the design time by co-engineering the solution with the equipment builder’s design department and providing packaged hardware solutions that are fully integrated into ABB's software. Once ABB releases packaged software solutions in addition to the hardware, the integration time will be reduced even further, saving costly time to successful deployment.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin