Aerotech Expands Automation1 Motion Control Platform With Version 2.8

Aerotech has released a new version of its popular motion control platform, Automation1, which includes new features for data acquisition, HMI visualization, and CNC machine features.

For more than fifty years, Aerotech has produced advanced motion control platforms for the automation industry. Recently, Aerotech added to its existing platform Automation1, which is a software and hardware suite for precision motion control. The new release includes enhanced motion control-focused features and allows for custom visualizations specifically designed for CNC machines.

Automation1

Aerotech’s Automation1 platform consists of motion controllers and software tools that control virtually any motor within Aerotech’s portfolio or third-party equipment. The software tools allow designers and technicians to configure, program, and store data for the associated system. The motion controllers provide sub-micron precision of automated motion control. The new release, version 2.8, comes with updates for recently released hardware, software tools, and customizable features.

Aerotech’s Automation1 version 2.8 now supports the 4-axis XA4 series controller. Image used courtesy of Aerotech

New Updates for Automation1 Version 2.8

The XA4 motion controller from Aerotech allows the control of up to four axes within one controller. This configuration saves panel space and reduces wiring time. It also enables programmers to blend motions between all four axes, creating smooth motion profiles for gantry systems or custom robotics. The new Automation 1 software release supports the 4-axis controller and EB1 and EB2 I/O expansion boards, giving designers the capability of inputs and outputs right at the motion controller.

Recording data has become a staple with automation equipment today. The data collected from motion controllers can be used for efficiency studies or to predict when equipment might need to be serviced. The parameters for these systems can be extensive and often only stored in local memory on the controller. Version 2.8 of the Automation1 platform allows designers to store multiple parameter sets so that operators can switch between parameters faster than manually entering new parameter sets. The onboard database also stores help files for the associated hardware. This allows operators and technicians quick access to manuals and wiring schematics from a single source.

Data visualization is often used to determine accurate and efficient tool paths or to track tool wear. Automation1 has improved the data visualization module with the ability to display 3D data signals. Viewing data at this level allows for a deeper understanding of tool paths and motion profiles.

Automation1 version 2.8 now enables users to customize CNC interfaces. Image used courtesy of Adobe Stock

Enhanced CNC Machine Features

CNC machines use precision motion control to move cutting tools around in physical space. For this reason, Aerotech has added tools to the Automation1 software specifically for CNC machine builders. New tools have been added for tool compensation and workpiece offsets, INI file support for offline saving of offsets and parameters, and 3D visualization. These features allow for a more precise motion profile and add flexibility to the machine interface.

The interface of a CNC machine is how technicians and operators work with the equipment: a solid and intuitive interface results in fewer mistakes and less downtime. Automation1’s new release allows for custom configuration of the software interface and provides new functions such as feedhold, retrace, and manual feed override. Custom screens, controls, and data visualizations can be made using the .NET library, allowing programmers to develop an optimized-looking HMI for CNC machines.

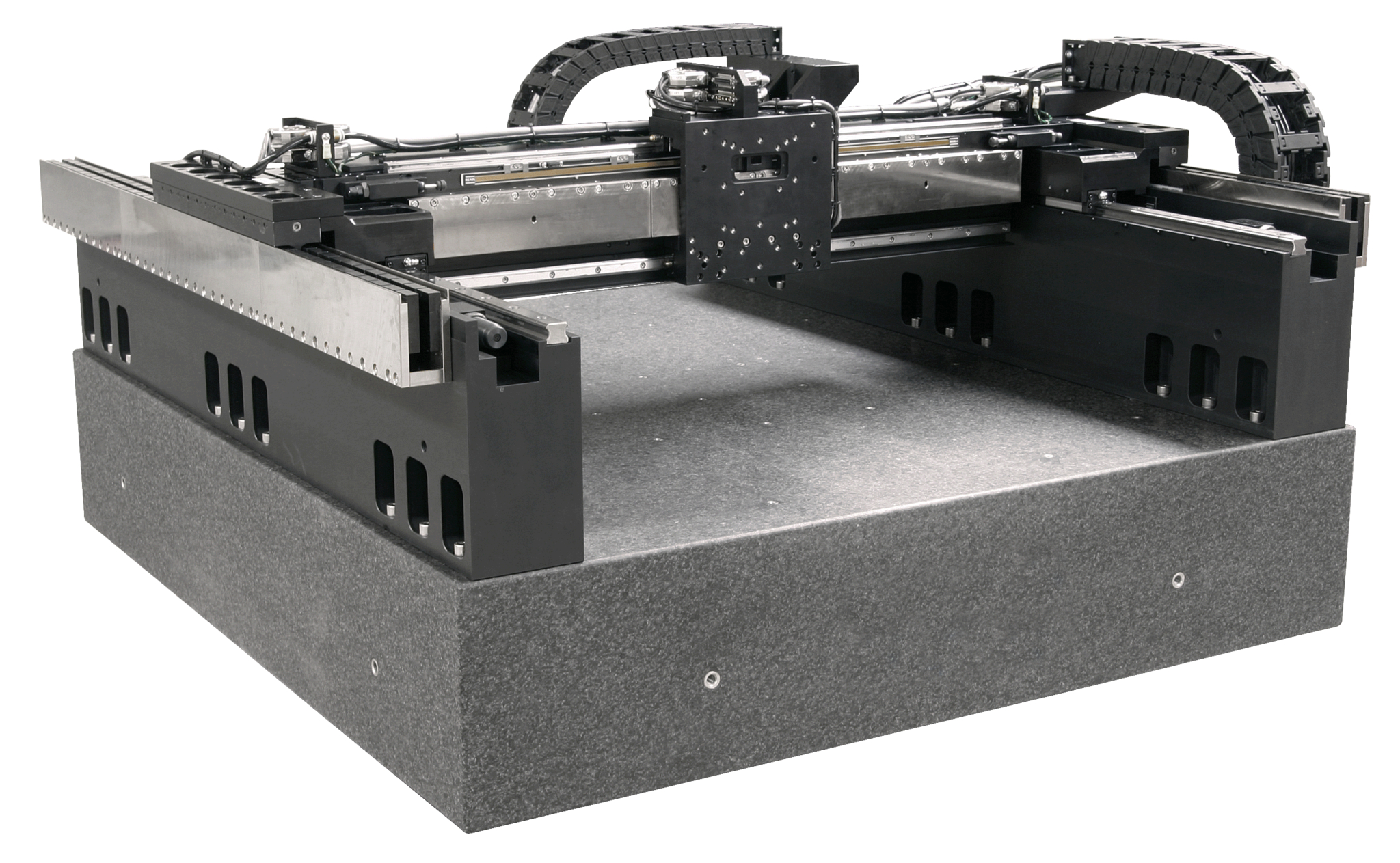

Aerotech servo gantry system used for inspection. Image used courtesy of Aerotech

Motion Control in Automation

Whether controlling a cutting tool or moving a product with a gantry system, motion profiles will determine if your equipment is running efficiently or wasting precious time. Collecting and analyzing data from your motion controller gives designers and technicians the power to develop efficient motion profiles. Automation1’s new release offers users the ability to create efficient and accurate motion profiles and the tools to showcase these profiles to their customers.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin