Agility Robotics Develops Cloud Automation Platform for Robot Fleet Management

Addressing labor shortages in logistics and manufacturing, Agility Robotics has released Agility Arc, a cloud-based automation platform that enables the deployment and management of bipedal robot fleets.

Agility Robotics demonstrated its newest automation tool, Agility Arc, at MODEX 2024 (March 11-14), the premier supply chain and logistics exposition. Agility Arc is a platform that enables users to manage fleets of robots, leveraging the cloud for shared knowledge, such as navigation, site mapping, and other critical information.

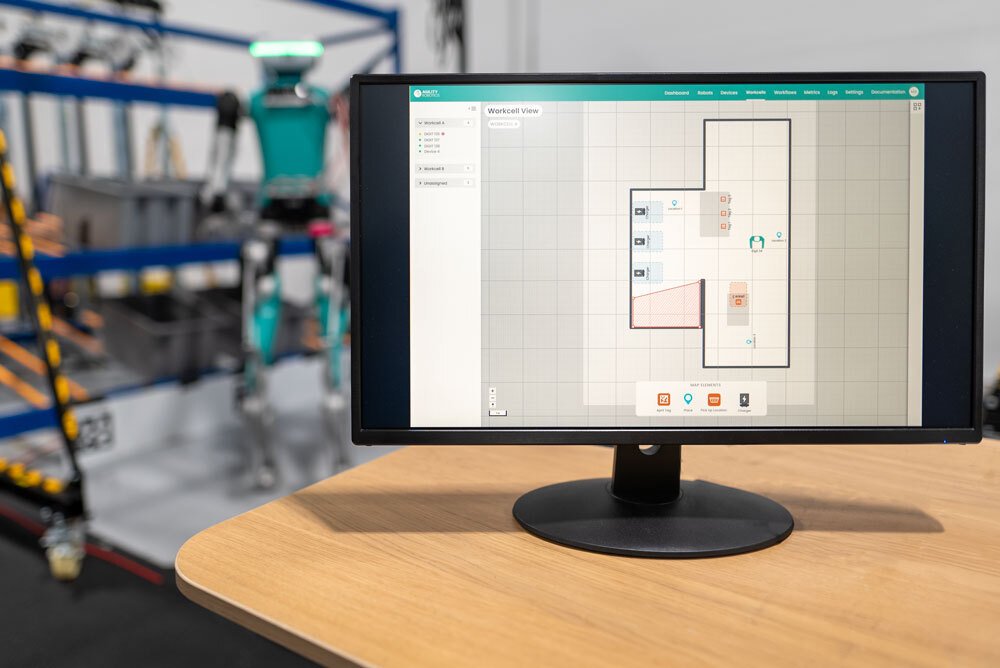

Agility Arc is a cloud automation platform that simplifies the deployment and management of Digit robot fleets. Image used courtesy of Agility Robotics

Agility Arc

Agility Arc is designed to work with Agility Robotics’ Digit robots. It is also designed to integrate quickly with popular warehouse management systems (WMS), warehouse execution systems (WES), and manufacturing execution systems (MES), making it a robust system for deployment in existing facilities that are already automated to some degree. It can also be used in new manufacturing plants and implemented from the very start of production.

The development of Agility Arc included extensive studies of warehouse and logistics automation systems to identify pain points, bottlenecks, and other problems where workflow and material flow could be optimized. By doing so, Agility Robotics has created Agility Arc as a software-as-a-service package that can be used to plan routes, track product workflows, and reduce the mean time before incidents (MTBI), drastically increasing the efficiency of manufacturing, packaging, and shipping operations.

Besides optimizing production, Agility Arc is accessible anywhere, allowing remote operation—yet it is also secure enough to prevent unauthorized access to data or controls. Furthermore, the user interface is streamlined to reduce the slope of the learning curve required for implementation and use by plant personnel.

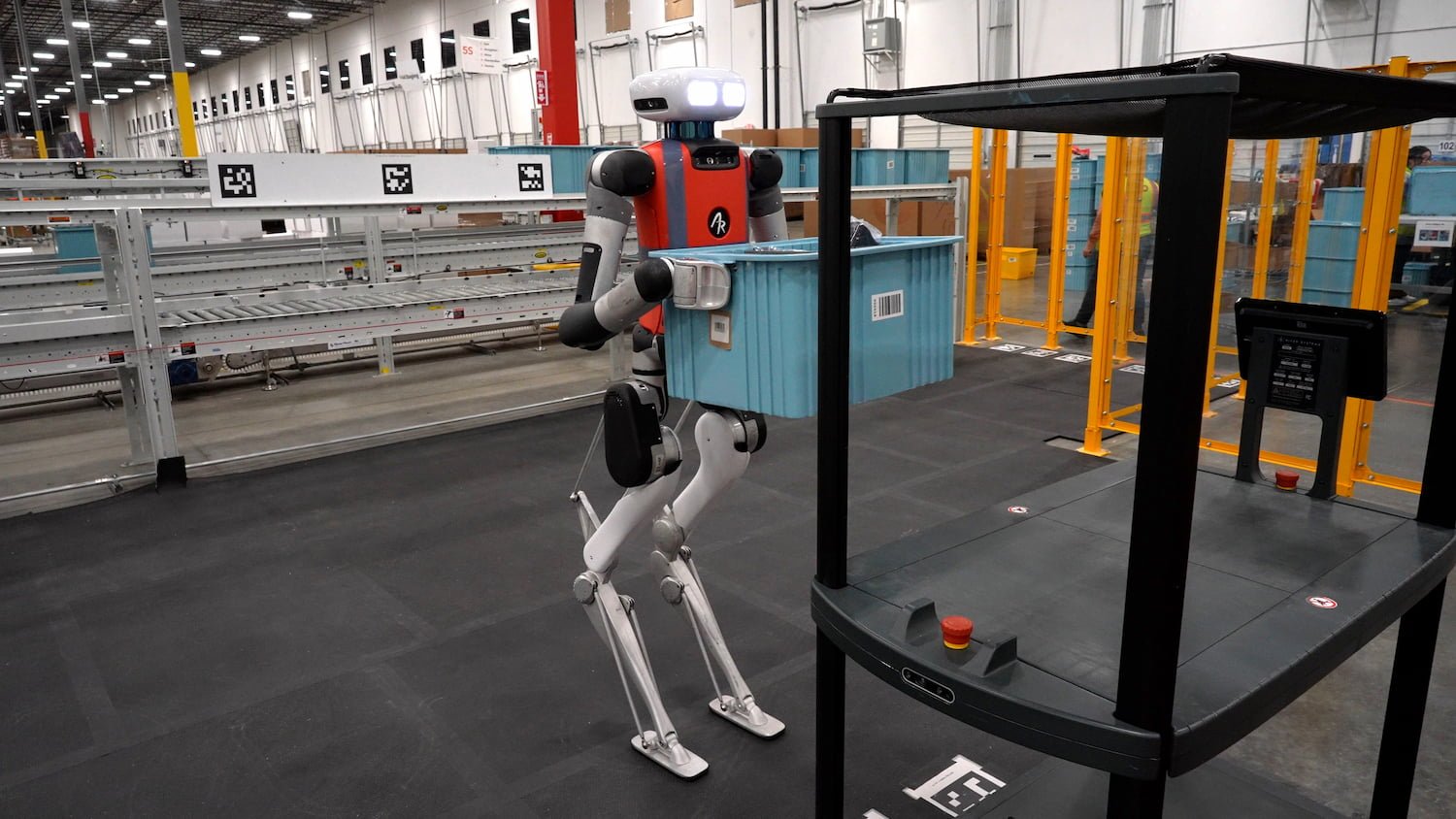

Digit is Agility Robotics’ bipedal robot designed to bring automation to human-centric spaces. Image used courtesy of Agility Robotics

Digit the Bipedal Robot

Digit is Agility Robotics’ bipedal robot used to transport and handle raw materials and goods. Like its human counterparts, it is designed to walk upright and navigate through logistics and manufacturing environments.

Designed in the image of humans, Digit can perform human tasks, except it can withstand higher and lower temperatures, make consistent movements, and not get tired, hungry, or bored. It is not designed, however, as a replacement for humans; rather, it is more like a dependable companion that can hold objects (up to 35 lbs) and perform tasks that are either potentially dangerous or repetitive for humans.

While one bipedal robot can help boost production, a fleet of them can make a very large impact. However, managing multiple robots at a time can be challenging. This is where Agility Arc can help. It integrates data from all of the robots, improving time and energy efficiency and optimizing the allocation of shared resources. Furthermore, this can be done from the comfort of a secure laptop in an office versus on the manufacturing plant floor, using the data that has been stored and processed on the cloud.

With Agility Arc, companies can automate operations on a larger scale, navigating ongoing labor shortages. Image used courtesy of Agility Robotics

A Robot Management Platform

Agility Arc will likely see use in shipping, receiving, and handling of goods and raw materials. Because it is designed to work with Digit, it will be used in areas of shared spaces with humans. With the ability to keep real-time maps and integrate with so many existing automation systems, Agility Robotics expects its new platform to be a popular “next step” for extending automation capabilities in manufacturing.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin