Akribis Systems Launches Rod Motor Positioning Modules With Repeatable, Submicron Accuracy

Akribis Systems utilizes its existing rod motor series in its new, linear axis designed for high speed and precision in the electronics, semiconductor, and battery production industries.

Global supplier of precision motion systems, Akribis Systems, has released a rod motor positioning module series that boasts submicron accuracy. The new system is fit for use in applications that require high precision accuracy, including the semiconductor, solar, and circuit board assembly industries.

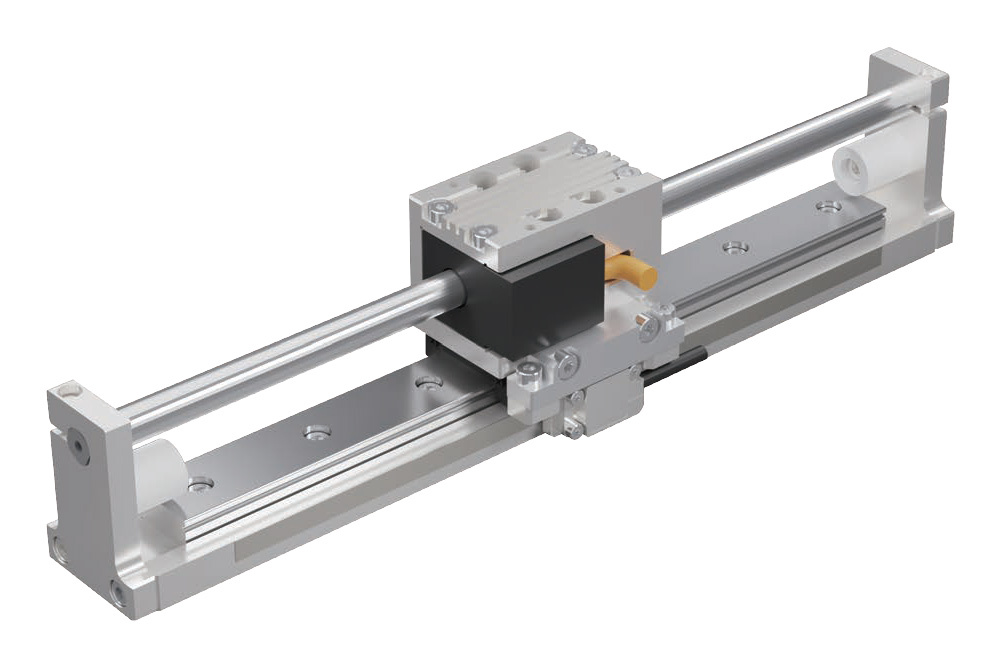

Akribis Systems’ SGR Series rod motor positioning module for fast and precise positioning. Image used courtesy of MyMepax

SGR Series Rod Motor Positioning Module

The new SGR series rod motor positioning module is a linear axis driven by an on-board coreless direct drive rod motor. The system includes linear guide rails, a contactless optical encoder, and an aluminum housing. This system is similar to a linear axis that would be driven with a servo motor and some gearing. Tooling can be mounted to the moving motor, and the encoder will provide accurate positioning when a driver is connected to the motor.

The SGR series is built for accuracy, providing a stable platform for rapid point-to-point motion. Its integrated optical encoder is capable of 0.2 µm resolution, and the direct-drive rod motor offers consistent force. The SGR comes in four sizes: SGR30, SGR40, SGR60, and SGR70. Each has different lengths ranging from 70 to 720 mm and different maximum continuous force capabilities. All four versions have the same ±2 µm repeatability rating.

The SGR series features an integrated Akribis Systems’ RDM-A coreless direct drive rod motor. Image used courtesy of Akribis Systems

Integrated RDM-A Series Rod Motor

The SGR series makes use of Akribis Systems’ RDM-A series rod motor, which is a coreless linear motor. Rod motors, sometimes referred to as linear motors, convert electrical energy to linear motion, typically with the use of gears or a belt system. This style of motor has no gearbox or pulleys but uses the same magnetic principles a motor would use, only the poles are in a linear topology.

The motor for the SGR module is mounted on a linear rail system, and a rod travels through the motor's core. When energized, the entire motor system travels along the rod, moving the attached tooling, and the optical encoder reports the position. Due to the magnetic force, an air gap between the motor coil and the motor ensures a consistent force is applied during the execution of motion. This motor doesn't use gears or belts, resulting in a cog-free motion. The maximum consistent force ranges from 3.1 to 114.8 N and a peak force of 9.3 to 344.5 N, depending on the model chosen.

The SGR series will bring submicron positioning accuracy to semiconductor, battery, and precision assembly applications. Image used courtesy of Adobe Stock

Submicron Positioning Accuracy

Moving tooling from one position to another is a common requirement with automated assembly equipment, and typically, a servo motor would provide your motion. With a linear motor such as the SGR module, you get compact, precise motion without all the bulky equipment and without scaling gearboxes, belts, and pulleys. The SGR series provides a unique way of fast, repeatable positioning useful in many industrial assembly applications.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin