Autonics ARIO: Packing I/O Capability Into a Small Form Factor

Scalability, network compatibility, and hot-swappable connections make data acquisition and process control straightforward with the new modular expansion I/O units from Autonics.

Autonics’ new ARIO series input/output (I/O) modules are designed for automation and data acquisition systems that are expected to be expanded or altered quickly. They feature hot-swapability and can handle up to 64 modules, meaning many data points can be collected for archival or process control decision-making purposes.

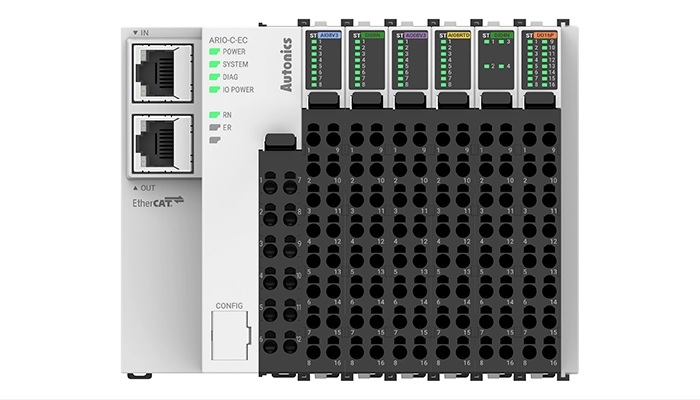

ARIO Series I/O Modules

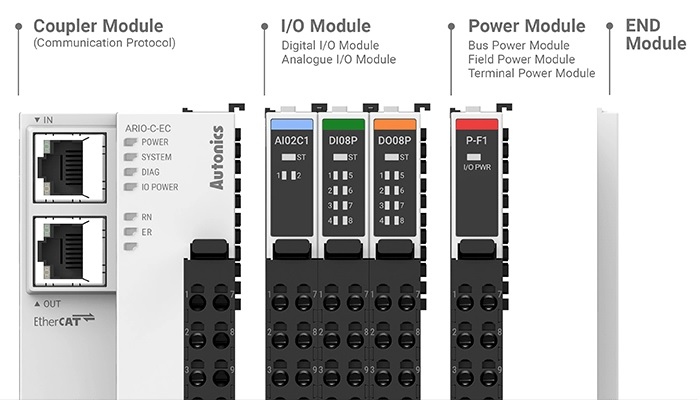

The ARIO Series system can be customized using four main sets of modules. Each system will have a coupler module, which makes communication to other controllers and computers possible. There are multiple I/O modules available, and this system is scalable such that multiple I/O modules can be connected together through the same coupler. The ARIO series will support up to 64 such modules combined through the same coupler module. There is a power module for situations where external power is required. Finally, there is an end module, which serves as a protective cap on the far end of the system.

The new ARIO series of remote I/O field modules. Image used courtesy of Autonics

Scalability

Scalability is one of the key features of this system. With the ability to connect up to 64 I/O modules through one coupler module, this system is highly customizable. It can be designed initially for a small, pilot-scale process but can rapidly be expanded into a full production line with many more data collection points.

There are several common I/O modules available as part of the ARIO series. Analog voltage or current, digital, RTD, thermocouple and others can be used as part of this system. The thin form factor (12 mm thickness) allows for plenty of data collection in a small footprint.

Read more | Comparing Analog Voltage and Current

Hot-Swappable

Another key feature is the ability to hot-swap modules. This makes troubleshooting and altering processes much more simple. Because the system does not need to be powered down to make changes, modules can be quickly replaced should one fail or if a new set of data needs to be collected.

Consider a set of digital inputs from one set of sensors. It is possible to have up to 16 digital inputs on one I/O module. This module has 16 wires that connect to sensors along one part of a process line. However, for a quick experiment, perhaps 16 more sensors are wired to another part. Rather than having to unwire and rewire 16 sensors, a second I/O module can be wired with the secondary set of sensors and swapped quickly into the coupler for quick access to critical measurements. This is particularly useful for maintenance tasks.

The four major components of the ARIO series I/O modules. Image used courtesy of Autonics

Communication Flexibility

In order to integrate with numerous industrial standards, the ARIO couplers provide connections to plenty of common fieldbus networks, including Ethernet/IP, EtherCAT, PROFINET, PROFIBUS, Modbus TCP, Modbus RTU, CC-Link V1/V2, and DeviceNet, making it easy to communicate with virtually any existing system.

Read more | Troubleshooting for PLC Modules and I/O Devices

Potential Markets

Virtually any industry can benefit from a hot-swappable, easily scalable, customizable data acquisition and control system, such as the ARIO Series. Autonics targeted the automotive manufacturing industry for the design of these modules. This particular market is rife with the need to collect many data points for quality assurance and product safety reasons. The ARIO Series modules make this data collection possible.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin