Balluff Creates New Flat Magnetic Targets for Angle Measurement Systems

Balluff’s latest absolute encoder features a low-profile design and highly accurate measurement to facilitate its use in compact motor angle measurement systems.

Balluff has recently announced the release of its latest encoder technology. The new system opens up unique possibilities for the automation industry, which extensively uses encoders to keep track of machine positions and rotational speed. Balluff’s latest Flat Magnetic Targets can help provide users with an accurate absolute encoder system that fits into a very low profile for increased application possibilities.

Why Motor Encoders are Important

Motor encoders are used to measure a motor's shaft's position, speed, and direction. They provide precise feedback to control systems, enabling accurate movement and positioning in various applications. Motor encoders are essential in robotics, automation, CNC machines, and other systems where precise control and monitoring of motor performance are critical. They help ensure accurate operation and enhance overall system efficiency.

There are two types of encoders common to the automation industry: incremental and absolute encoders. Absolute and incremental encoders are both used to measure position, but they differ in how they provide this information. Incremental encoders measure position based on changes from a reference point, providing information about movement and direction rather than the exact position. They require a reference or "home" position to determine the absolute position after restoring power.

The latest encoders from Balluff are absolute encoders. Absolute encoders provide a unique position value for each shaft angle that always gives the exact position, even after power loss. This ensures that the system knows the precise position immediately upon startup. Absolute encoders provide valuable feedback and a high accuracy for applications that require it.

The Latest Absolute Encoders from Balluff

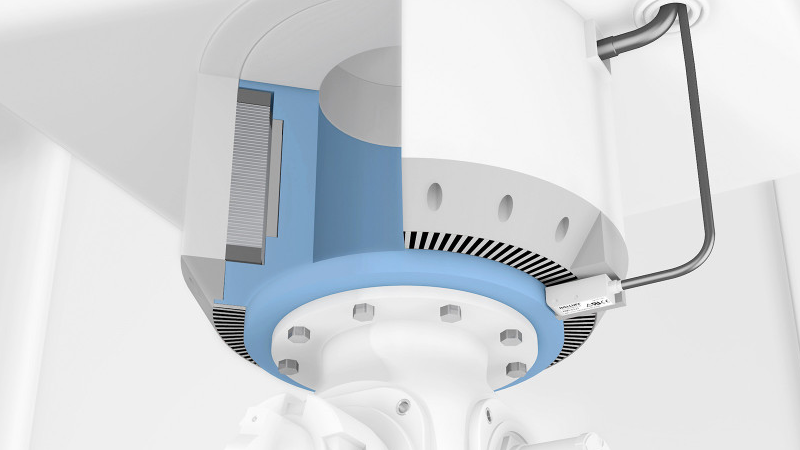

Balluff's Compact BML magnetic encoder systems are designed for precise positioning and speed detection in most automation environments. They encompass ultra-thin magnetic disks that provide highly precise magnetization data.

They can operate without requiring a reference point, ensuring the drive’s exact position is always known. The system maintains accuracy even with large diameters, and the compact size allows for easy integration into tight spaces in electric drives and drive axes. For high-volume applications, the absolute encoding disks can be paired with common off-axis encoder ICs or Balluff's own compatible sensor modules.

The latest encoder system from Balluff features a compact design to fit into small spaces. Image courtesy of Balluff

The flat magnetic encoders have some exciting features, including

- low overall height for easy integration

- different sizes for unique motor diameters

- precise absolute measurement

- a robust design.

Smaller Motors Need Smaller Encoding Systems

Torque motors are increasingly being designed in smaller sizes to meet the demands of applications requiring high power density. Their compact, low-profile design allows for nearly invisible integration into various systems. However, this compactness presents challenges for measuring systems that need to be embedded within the motor to provide accurate feedback from the coil to the controller.

Balluff’s rotary magnetic encoder systems with flat magnetic disk targets offer an ideal solution. These disks can be installed into tight spaces, fit any motor size, and withstand harsh conditions. They precisely measure rotary movements for accurate motor control and position regulation, ensuring consistent tool positioning in machining centers. They are also resistant to dirt and vibration and require no maintenance over extended periods.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin