Banner Engineering Expands Modbus Capabilities With a Hybrid I/O Hub

Banner Engineering has released a multipurpose hub that works with its existing line of Snap Signal devices, combining discrete inputs and outputs along with analog inputs and analog port mirroring to pulse-frequency modulation outputs.

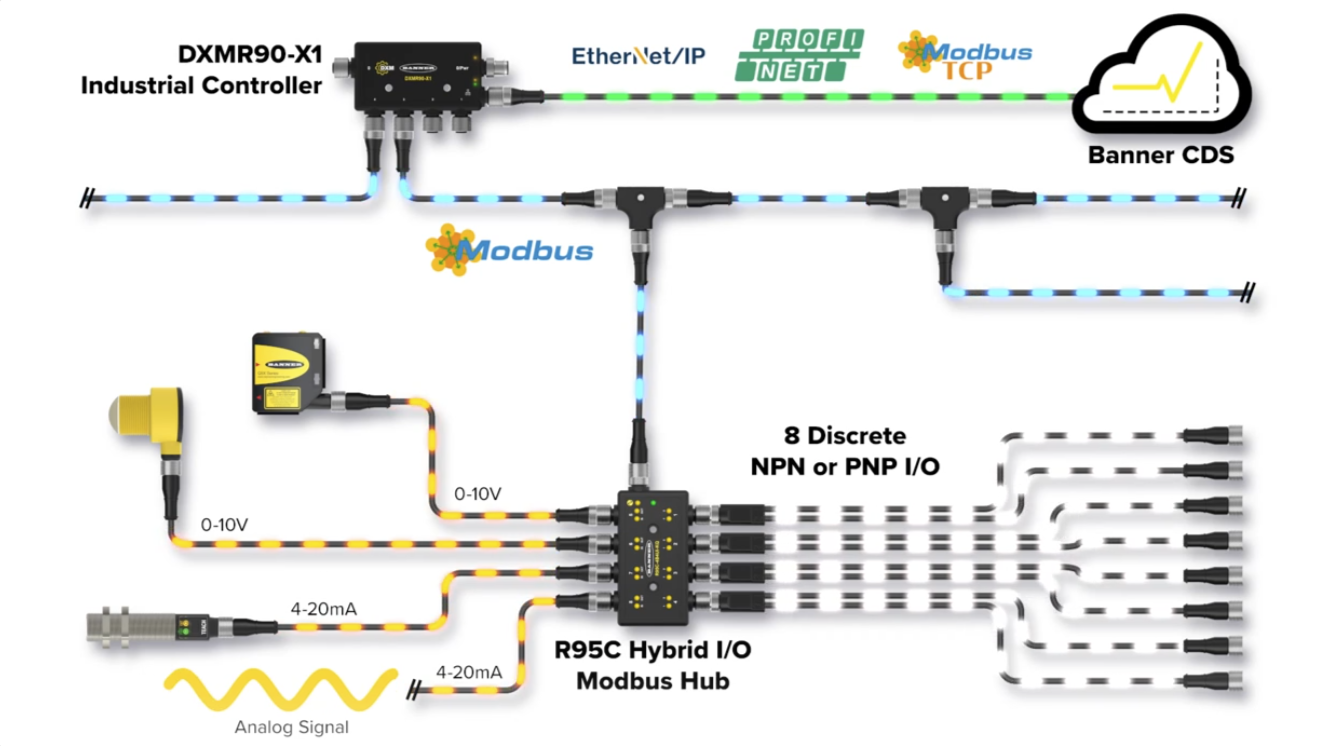

Known worldwide for its automation sensors, switches, and safety components, Banner Engineering is once again releasing components that promise to decrease wiring and installation time. The company has expanded its Modbus remote I/O capabilities with the new R95C, a multipurpose I/O hub capable of monitoring discrete NPN or PNP inputs and outputs along with analog inputs.

Banner Engineering’s new R95C Hybrid I/O Modbus Hub. Image used courtesy of Banner Engineering

R95C Hybrid I/O Modbus Hub

Built on the popular Modbus topology, the new R95C hub combines eight discrete NPN or PNP inputs and outputs on four physical ports along with four analog inputs that can be configured for voltage or current signals. The eight ports all connect on two sides of the hub with one main communication connector at the top of the device.

The R95C can be stacked and connected, forming a network of remote I/O, and when connected to a DXMR90 controller, the Modbus signal can be converted to Ethernet/IP, Profinet, or Modbus TCP. Bright LEDs on the device's face show each port's input-output status, and a connection status LED shows the status of the Modbus connection.

All of the connection ports use the industry-standard M12 connectors with the I/O ports being four-pin and the communication port using a five-pin connector. The device is powered by 18 to 30 VDC, and each discrete output is capable of passing through up to 200 mA per channel. The R95C's housing has mounting holes and is IP67/IP68 rated, making it an excellent field-mountable remote I/O hub.

The R95C Hybrid I/O Modbus Hub’s multipurpose ports enable greater design efficiency. Image used courtesy of Banner Engineering

Port Mirroring

All four of the analog input ports are capable of mirroring to any one of the discrete output ports for pulse-frequency modulation (PFM) signals. Analog signals require special scaling and programming to ensure the signal is being read correctly. With the R95C in port mirroring mode, the analog signal is converted to a digital representation of the analog signal, sometimes referred to as PFM.

A PFM signal uses a fixed pulse width and modulates the frequency of the pulses. As the analog signal grows, the number of pulses per second will increase; similarly, as the signal falls, the frequency of the pulses will reduce. This feature is useful when combined with Banner's lighting products, creating a visual representation of the analog input signal.

With the new R95C hub, users can update old equipment with modern technology. Image used courtesy of Adobe Stock

Data Collection of Brownfield Equipment

Data collection and analysis costs have greatly reduced over the years, partly because of cost-effective computers and software. Manufacturing engineers are now requesting data collection on equipment installed and running for many years, also known as brownfield equipment. With devices like the R95C, integrators and maintenance staff can easily mount sensors, both discrete and analog, where needed to collect required data. Connecting the Modbus network to a converter allows virtually any control system or analysis software access to monitor the I/O state. Using an I/O configuration like this brings older equipment up to date with modern technology.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin