Banner Introduces New Multipoint Sensor for Wide Area Detection

The new K50Z multipoint sensor from Banner Engineering is equipped with the latest technology to detect hard-to-see items over a wide area. The new sensor serves as an alternative to the use of several single-point sensors.

Banner Engineering has a new solution for scanning large areas: the K50Z multipoint sensor, which can detect objects during picking, packing, and machine tending operations. This new laser sensor scans a wide area and can detect traditionally difficult-to-find or irregularly shaped items.

Banner Engineering’s new K50Z multipoint sensor for wide area detection. Image used courtesy of Banner Engineering

What Is an Area Scanner?

Area scanners use a laser and measure the return time of the beam to determine if an object is located within the scanning range. These scanners have multiple uses, with perhaps the most common use to detect objects needed for picking, packing, and machine tending operations. Sub-assemblies, completed products, or raw materials are left in a bin. The area scanner can detect where these objects are and use the output to direct other automation, such as robotic arms, to where to find the objects.

K50Z Multipoint Sensor

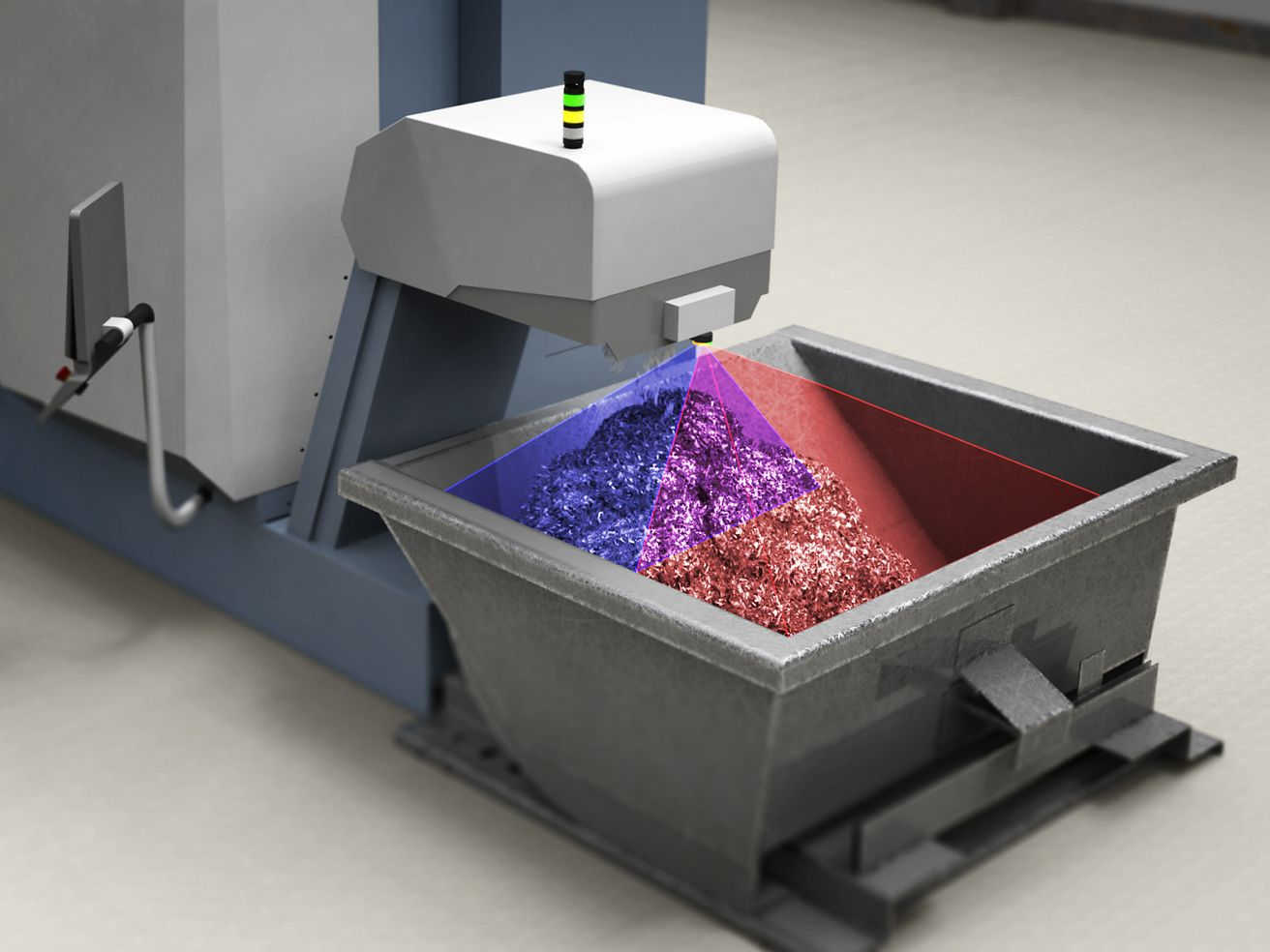

Banner's new K50Z series detectors are class 1 laser sensors used for finding irregularly shaped or inconsistently situated items in bins or containers. These particular sensors have been tested against metal wire bins, which are commonly used for holding large parts but are often fooled by laser sensors due to the large air spaces in them.

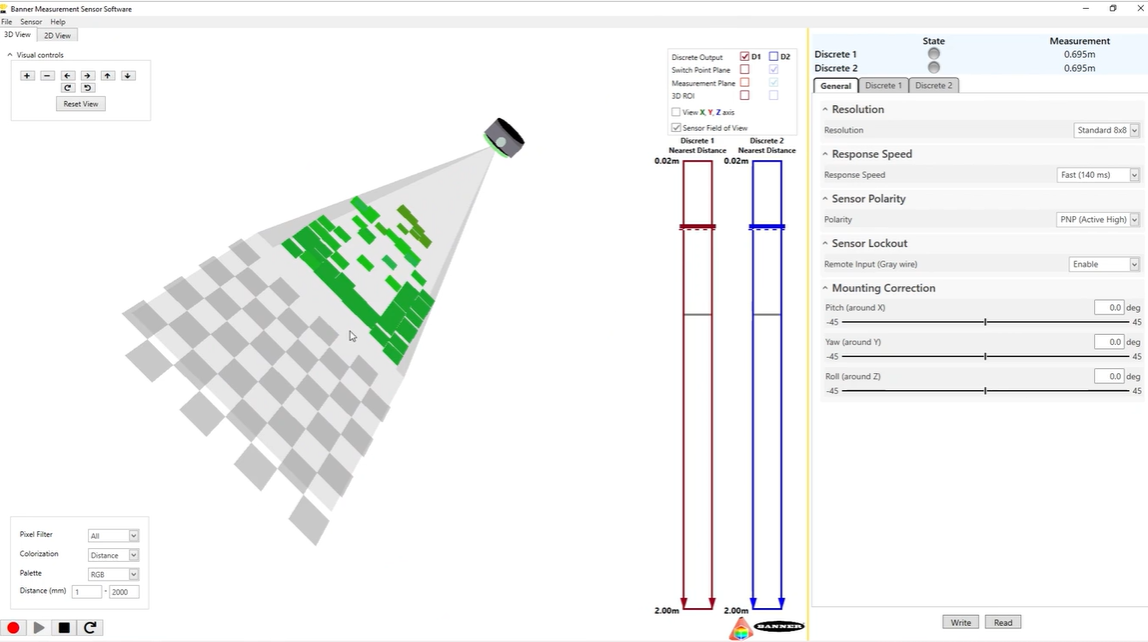

Software configuration of the K50Z series sensor, showing the scanning grid and some of the thresholding parameters. Image used courtesy of Banner Engineering

The K50Z multipoint sensor uses a time-of-flight (ToF) routine across an 8 x 8 pixel array utilizing 64 detection points. It performs this operation with a wide field of vision (45 degrees x 45 degrees). This array can see objects as close as 20 mm and as far away as 2 m. If large objects are being detected, the sensor can trade resolution for speed, switching to a 4 x 4 (16 detection points) mode.

One neat feature of the K50Z sensor is its ability to scan two separate regions and output them to two separate ports. For example, consider feeding two sets of polymer beads into a blending process for an injection molder. The sensor could be configured to scan each hopper separately and look for problems in feeds. Furthermore, these feeds can be thresholded independently, meaning beads with different feed rates or sizes can alarm under various criteria, with all data coming from the same sensor.

The K50Z sensor can monitor fill levels across large areas to prevent overfill in singular regions in a bin. Image used courtesy of Banner Engineering

Wide Area Measurement and Detection

Due to the wide beam area and multiple detection points, Banner's new sensor is suitable for picking and packing operations, even with traditionally challenging objects, such as mesh carts and pallets that have holes, which can be fooled by lesser sensors as the beam passes through the gaps. The ability to detect close objects, or objects up to two meters away, even if the object is irregularly shaped, makes the K50Z a versatile sensor for the shipping and machine tending end of automation lines.

This sensor may also be used in powder or object-feeding bins, where it can detect irregularities in the surface of the feed material. Powders will "bridge" or "rathole" based on static charge, unoptimized chute or hopper angles, or a variety of other conditions. With the K50Z series sensor, these problems can be detected early.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin