Boeing and Bae Systems, Exail and NATO Reach Strategic Military Agreements

This article surveys the latest control technology in aerial military systems and dives into the latest technologies surrounding underwater mine countermeasure operations.

Boeing has partnered with Bae Systems, Inc., leveraging the latter’s 40-plus years of flight control technology expertise to revamp Boeing’s fly-by-wire (FBW) flight control computers (FCC) for two of its fighter aircraft. In other news, Exail Robotics announced receiving a 60 million euro order from NATO to supply K-Ster C underwater mine disposal vehicles to Belgian and Royal Netherlands navies.

In August, the F/A-18 Super Hornet, one of the first ever built, was unveiled at The National Museum of Transportation in St. Louis, Missouri. Image used courtesy of Boeing [video]

Electronic vs Mechanical Controls

Boeing intends to upgrade its original FCC system for Boeing’s F/A-18E/F Super Hornet and F-15EX Eagle II fighter aircraft. Boeing also wants to add another processor to the F/A-18E/F FCC. The FBW technology is partly automated and runs computer-mediated flight control for aircraft.

Flight control computers adjust actuators on flight control surfaces based on the interpretation of electronic signals that reflect physical/manual inputs on flight control by pilots. Therefore, fly-by-wire technology takes manual flight controls and swaps them with an electronic interface.

Whereas mechanical controls integrate several components that make systems heavy and hard to maintain, electronic FBW systems reduce the number of system components, reducing complexity and weight. The positive benefits here include reduced maintenance as well as enhanced fuel efficiency.

Quad Redundancy for Enhanced Safety

The FBW flight control systems (FCS) are quad-redundant, which means that they incorporate four separate paths for processing control commands. This redundancy enhances safety and system reliability in case one or more control processing paths are compromised during flight.

Because the FBW system can evaluate outputs over all four paths to identify anomalies or mistakes and isolate them to ensure only the proper control signals are sent to the aircraft's actuators, quad redundancy also helps in fault detection.

NATO Order for Highly Adept K-Ster Mine Killers

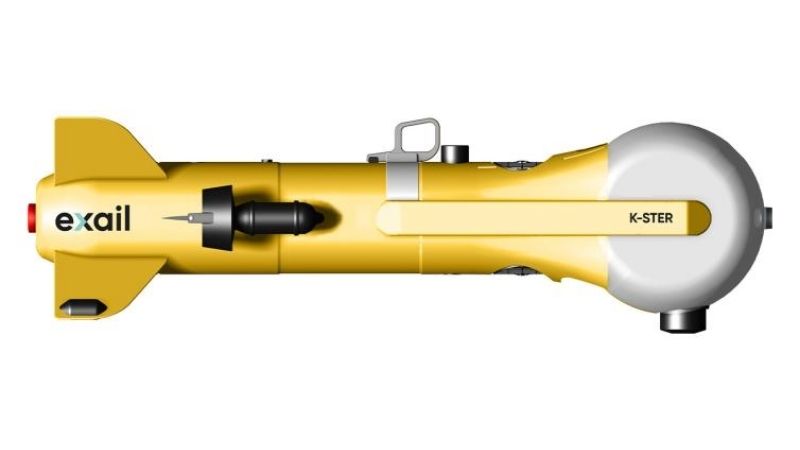

Additionally, NATO has agreed on a 60 million euro contract with Exail Robotics to produce and supply K-Ster C underwater mine disposal vehicles and other training equipment. The order, placed by the NATO Support and Procurement Agency, is intended to help shore up Belgian and Royal Netherlands navies. The new contract builds on an existing relationship between Exail and the Belgian and Royal Netherlands navies, expanding and modernizing their mine disposal capabilities.

An overview of the UMIS system in action, featuring the K-Ster mine-killing vehicle. Video used courtesy of Exail

Customers can operate the K-Ster C underwater vehicles from a management and control unit on land or at sea via an unmanned surface drone platform. The remotely-operated mine-targeting solution complies with NATO standards, incorporating technologies that mitigate acoustic and magnetic signatures.

The K-Ster features a powerful shaped charge for neutralizing an array of mine types (historical, floating, or partially buried). Its battery-powered design facilitates operations in high currents of up to 4 knots.

The K-Ster mine-killer can neutralize a variety of mines even in high currents. Image used courtesy of ECA group (Exail)

As a fully integrated mine disposal and management system, the K-Ster mine-killing vehicles can be deployed as part of Exail’s Unmanned Mine Countermeasure Integrated System, UMIS. UMIS features unmanned surface and aerial vehicles, towed technologies (such as sonars and sweeps), and UMISOFT software suite for end-to-end management of unmanned mine disposal operations.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin