Cognex Announces the “World’s First” AI-Driven 3D Vision System

Cognex has created a new AI-driven vision system that uses 2D and 3D vision with AI technology to give users a more easily deployable vision system for inspection and measurement applications.

Cognex, a frontrunner in industrial machine vision, has recently unveiled the In-Sight L38 3D Vision System, hailed as the “world’s first” truly AI-driven 3D vision innovation intended to solve the most challenging measurement and inspection applications.

AI Enables Fast Deployment and Reliable Inspections

This camera and software setup combines the power of AI with some of the most reliable 2D and 3D vision technologies to revolutionize applications that already commonly rely on machine vision.

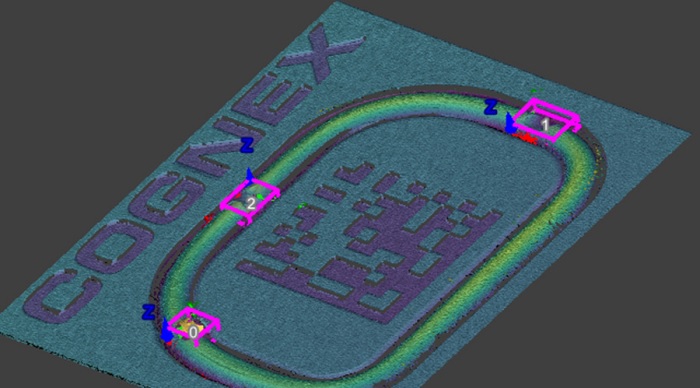

AI-driven 3D vision offers enhanced capabilities for challenging vision tasks through the combination of 2D, 3D, and AI image technology. Image used courtesy of Cognex

The new technology generates distinct projection images that combine 3D insights into easily interpretable 2D visuals. Cognex hopes the system will facilitate simplified training and find use in uncovering intricate features imperceptible to conventional 2D imaging methods. Through the utilization of AI tools, variable or undefined features are identified, while rule-based algorithms are used to furnish precise 3D measurements, helping deliver dependable inspection outcomes.

The In-Sight L38 Creates New Possibilities

Cognex developed the product for factory automation, prioritizing swift deployment and reliability among the design criteria. The In-Sight L38 provides a way to go beyond the idea of a traditional 3D vision system by incorporating AI-powered technology to supply automated inspections with higher levels of quality and efficiency.

The In-Sight L38 transforms legacy 3D system configuration by using embedded AI technology capable of leveraging pre-trained models. The pre-trained models are infused with domain-specific data to help with precise learning. The use of pre-trained AI models can replace intricate programming procedures. In addition, example-based training can help create a streamlined method. Between the two, the need for combining numerous traditional rule-based tools can be eliminated, helping to expedite application development.

The combination of precise vision and AI processing can identify subtle and variable feature errors outside of a strictly teachable scope. Image used courtesy of Cognex

Setup and Training of AI Vision

The AI-driven 3D tools can be set up with a minimal amount of input information. In some cases, initial training requires as few as 5 to 10 labeled images to automate a task. The tool enables users to identify intricate defects, assess variances in three dimensions, and obtain results in real-world units with a reduction in time and effort compared to other options.

The In-Sight L38 contains patented, speckle-free laser optics allowing it to capture images at a higher resolution as compared to conventional laser displacement sensors. Additionally, the In-Sight L38 can mitigate visual noise and glare, further helping to create clearer images for use with AI models. The high-powered laser ensures rapid acquisition rates to support higher manufacturing speeds, meeting Class 2 safety standards, meaning the elimination of the necessity for costly enclosures. Enhanced light emission reduces exposure requirements and facilitates increased product line speeds helping to increase throughput.

Cognex: a Leader in Vision Technology

Cognex Corporation pioneers and commercializes technologies that are useful in dealing with crucial manufacturing and distribution challenges. Cognex is a global leader in machine vision, where they offer solutions enhancing efficiency and quality in diverse industrial sectors. Their products integrate the latest hardware and software to capture and analyze visual data, enabling automation in manufacturing and distribution to a worldwide audience.

Machine vision optimizes processes by locating, identifying, inspecting, and measuring items like mobile phones, electric vehicle batteries, and e-commerce packages. With the latest AI driven 3D Vision addition, the In-Sight L38, Cognex hopes to give end users and integrateters a superior product that can help to improve functionality while decreasing time for the onboarding process.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin