Comau Launches AI-Powered Vision System for Robotic Piece Picking

Comau has released an autonomous piece picking solution that utilizes intelligent vision hardware and advanced AI software. The solution enables robots to pick different objects randomly scattered in a bin.

A common problem in automation is picking parts that are randomly placed in a bin. This operation is often left to human operators because of the complex vision and robotics required to pick parts at random. Robots prefer to have parts in a consistent place for a consistent pick every time.

When a robot needs to pick a variety of different parts in random locations and orientations, it needs a vision system and, frequently, a 3D vision system. These systems require users to program complex vision applications and integrate complex robot applications. Comau hopes to change all that with the introduction of its intelligent piece-picking solution, the MI.RA/OnePicker.

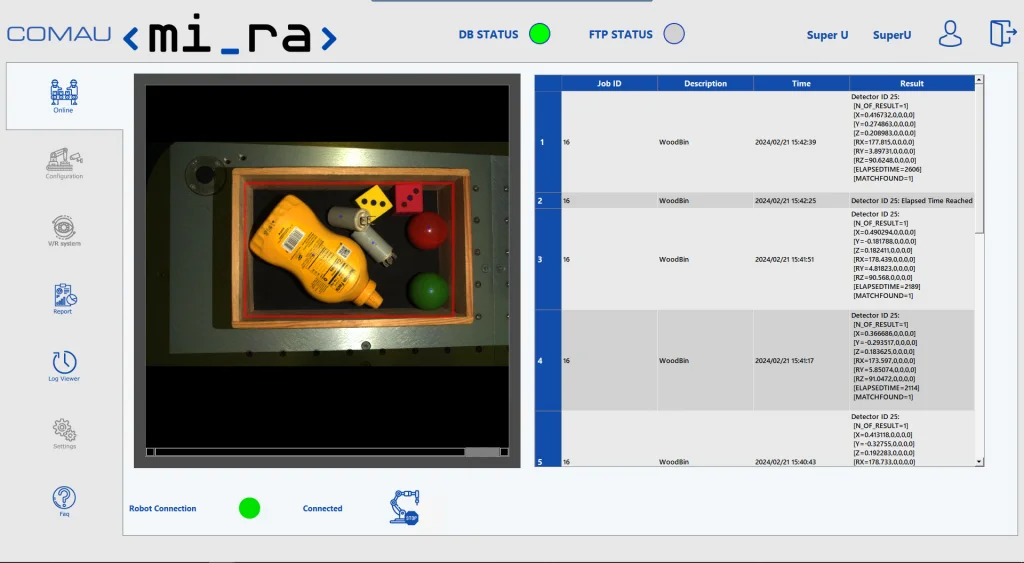

Comau’s MI.RA/OnePicker is an AI-powered vision system for fully-automated piece picking. Image used courtesy of Comau

MI.RA/OnePicker

Comau’s MI.RA/OnePicker combines a robot, a vision system, and advanced sensors. The system uses artificial intelligence to calculate a picking pose for each randomly displaced object within a bin. The system can plan out the most efficient pose and method of emptying a bin of random items. The MI.RA/OnePicker can perform these duties without CAD-based assistance or having prior information about the item's size, color, or shape.

Robotic Path Planning

In most robot applications, the robot programmer decides the path the robot will take to pick up the distended part and where to place it. However, with an autonomous system, the robot will need to determine its path. The MI.RA/OnePicker solution can develop its paths with the help of virtual simulation tools, which offer collision-free trajectories that are efficient in helping reduce unnecessary movements and overall cycle time.

A Zivid structured light camera fixed to Comau’s Racer-5 COBOT. Image used courtesy of Comau

Device Agnostic

The MI.RA/OnePicker can be ordered as a complete solution with Comau's Racer-5 COBOT, a robot that changes between industrial and collaborative modes. The system is also designed to be usable with any other robot on the market. The system supports two types of cameras: a Zivid structured light camera or an Intel RealSense stereo camera. Customized grippers and customized bins can also be easily integrated into the MI.RA/OnePicker system.

The MI.RA/OnePicker solution enables autonomous picking of random objects. Image used courtesy of Comau

3D Robot Guidance

Vision-guided systems can be quite complicated and require months of integration time, but they can also help robots pick complex shapes and increase picking accuracy. Often, the vision system has a development environment different from the robot's, so coordinate systems need to be aligned, and data needs to be passed back and forth between the robot and the camera.

Comau has made a valiant effort to reduce this complex topology with a setup tool that gives users all the necessary parameters. With the MI.RA/OnePicker, users simply enter parameters that the algorithm will use to define robot paths and gripping locations. Comau has included a set of predefined routines that include popular scenarios to make the integration process even less painful. A merge feature also allows users to merge existing robot programs with ready-made programs.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin