Comau Releases End-To-End Manufacturing Solution for Hairpin Stators

In response to the automotive industry's growing demand for electric motors, Comau has launched a catalog of advanced, fully automated machines specifically designed for the production of hairpin stators.

For over fifty years, Comau has been a global supplier of assembly and machining technologies for the automotive industry. It manufactures industrial robots and digital IoT platforms. Recently, Comau announced a full portfolio of machines for the production of hairpin stators used in electric motors. These motors are used in electric vehicles and require different assembly processes than traditional motors.

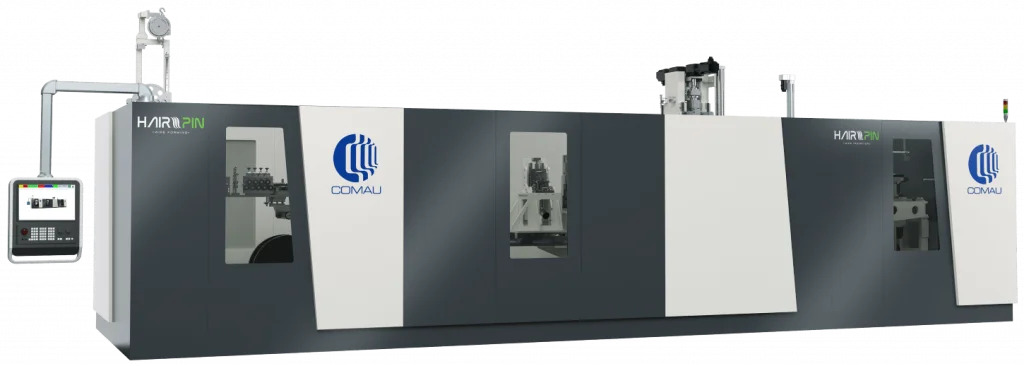

Comau’s hairpin stator technology portfolio is made up of different stations, including wire forming, insertion, widening, twisting, cutting, and welding stations. Image used courtesy of Comau

Hairpin Stator Manufacturing

To stay competitive in the electric vehicle manufacturing industry, Comau has released an entire line of machines specifically designed to produce hairpin stators used in electric motors. The catalog includes wire-forming, insertion, twisting, and laser welding machines. These machines are not one-size-fits-all; they are customizable and flexible, allowing the equipment to grow with the manufacturer.

Each machine has been optimized to have the smallest possible footprint and possess a lean production set-up. Real-time monitoring of the automated process allows quality technicians to catch issues before they become unrecoverable. With this equipment making parts for electric vehicles, Comau spent time designing the equipment to be as energy-efficient as possible.

Comau’s wire forming and wire insertion station. Image used courtesy of Comau

Wire Forming and Insertion

The wire forming machine is a fully automatic machine capable of unwinding, straightening, removing paint, cutting, 2D numerically controlled (NC) forming, and 3D mold forming. Its overall cycle time is less than 2 seconds. The straightening process has less than 0.2 mm accuracy, and the paint removal solution is configurable for laser mechanical processes.

The machine requires no manual intervention and has a high throughput rate. It uses an ultra-high speed gantry to insert the formed wires into the stator. Insulating paper is pressed in between the wires using a corolla press. The wire insertion machine is compatible with many different wire shapes for various product types.

Comau's wire cutting station. Image used courtesy of Comau

Wire Widening, Twisting, and Cutting

The shaping of the wire is completed with the widening twisting and cutting machines. These machines use precision servo and cam-driven technologies to supply a configurable end product. Special designs in the equipment reduce burrs during cutting, produce smooth twisting actions, and allow for multiple programs to accommodate different stator part types.

Comau’s wire welding station. Image used courtesy of Comau

Wire Welding

The wire welding machine uses laser welding technology to ensure deep penetration of the weld and produces a high pull-out force. Multiple welding programs can be loaded into the machine, accommodating multiple part types. A single welding machine option is available, or a combination of cutting and welding can be provided in one machine for better production efficiency.

Production on a Global Scale

The hairpin stator process modules are produced in Comau’s Center of Excellence of E-Motor Technology facility in Shanghai. By making equipment in this location, Comau can supply a global market while still maintaining roots in an area thriving in the electric vehicle industry.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin