Construction Gets a Boost With 1200CX Drywall Robot From Canvas

Applying the mud and sanding the wall in prep for painting is one of the most meticulous, yet laborious tasks in a construction project, but the burden is eased thanks to a new automated solution.

Hi, my name is David, and I really hate finishing drywall projects.

Much to the joyous appreciation of construction crews around the globe, San Francisco construction automation company Canvas just announced the 1200CX drywall finishing robotic platform, leveraging the safety and ease of programming afforded by Universal Robot’s popular UR10e model.

Challenges of Drywall Finishing

Innovations like the 1200CX drywall finishing robot are intriguing because the device addresses challenges across two industries, instead of simply solving a problem within a single manufacturing or automated process. The construction industry has a continuous need for the completion of laborious tasks, of which drywall finishing is not the easiest, but perhaps one of the more repetitive. Additionally, a robot platform for the construction industry must be easy to set up and operate so that a construction crew does not need to rely on the rapid assistance of a trainer robotics expert.

Two notorious challenges appear through the drywall finishing process. The first is the application of the ‘mud’ (or, more formally, joint compound of various viscosities). The mud is placed over the joints between drywall sheets along with a special tape to bond two adjacent panels. After sufficiently drying, the surface is sanded to remove imperfections and create a smooth surface for texture and paint spray. The joint compound and sanding applications are very laborious, and although they are best suffered, I mean, completed, by experts with a trained eye, the process is quite repetitive. In other words, a great place to insert a robot.

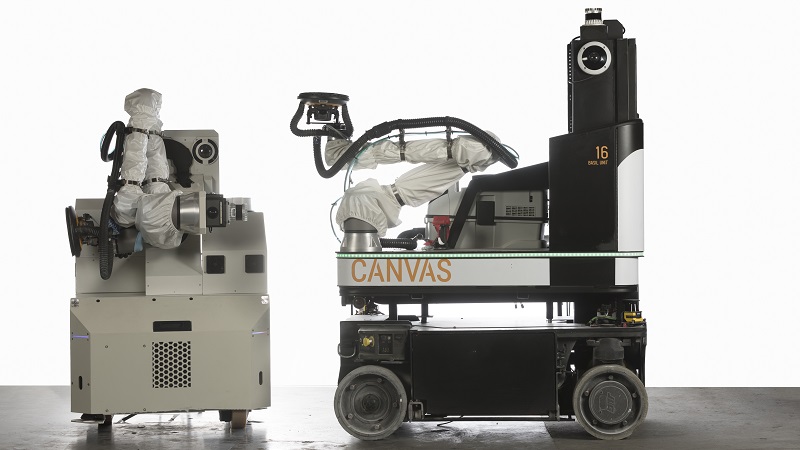

The news 1200CX drywall robotic platform with a UR10e. Image used courtesy of Canvas

Specs of the Canvas 1200CX

This model is designed from performance improvements and special configurations to supplement the existing 1550 platform. The previous model (as can be interpreted from the model number) has a finishing height of 15.5 ft, but not all projects require this extended height. The new 1200CX is designed for wall panels or sections up to 12 ft in height, being the standard single-panel length for walls over 8 ft.

Being battery-powered on wheels, the mobile platform can run all day on a single charge, and the all-wheel steering provides the ability to roll into tight corners so that entire wall lengths can be completed from corner to corner.

The joint compound is applied with a spray-on method rather than with the familiar trowel and bucket. This allows much more consistent and rapid application. After drying, the tool is switched with a sanding head and a vacuum which removes 99.9% of dust in the air. That dust is a hazard not only to crew health, but also to the service life of the robotic platform, so removing the dust is essential.

Help for Construction Companies Around the World

Because of the scale of this machine, it should be noted that it is better suited for companies investing in large projects like multifamily residential, hospitality, hospitals, airports, education, and office spaces. Regular folks like you and I working on our home projects are far less likely to capture an ROI from such a device, convenient as it may be.

The 1200CX completes a task on a tall wall section. Image used courtesy of Canvas

Construction automation is, perhaps, slower to adopt robotic applications than some other industries. This is due to the custom nature of every project, and even the many variations that appear within the scope of even a small project. But for those tasks that can be automated, this frees up the construction crew to perform the tasks which are not as simple for a robot to handle.

A highly positive side effect of robotics in construction is the ability for crews to learn new skill sets when deploying robotic systems. The UR series from Universal Robots provides a simple programming user experience, and it can be a great platform for construction companies to explore the beginning of automation opportunities to build better, faster, and more safely than ever before.

Live long and prosper, and may you never need to manually mud, tape, and sand a wall ever again.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin