ControlByWeb Adds New Cellular Connection to I/O Controllers

Adding wireless to PLC projects poses challenges, namely security and project complexity. ControlByWeb seeks to overcome those barriers and add cellular data to the newest controller versions.

Cellular data connectivity is now available as a primary or backup method on the newest versions of I/O controllers from ControlByWeb. Wired data connections, such as Ethernet, are prevalent for industrial automation applications, but they are limited by cable distance which can constrain the variety of applications and project flexibility.

The new I/O controllers with cellular connectivity enabled. Image used courtesy of ControlByWeb

ControlByWeb PLC Products

Many commercially available gateway devices already exist to convert data streams from a central control system into any variety of network outputs, both wired and wireless. Examples include Ethernet, Wi-Fi, Cellular, Bluetooth, and other industry-specific models, each with unique packet types to link to MQTT brokers, servers for data storage, and industry protocols (Modbus, PROFINET, etc). In short, there is an endless variety of products to convert data.

ControlByWeb offers a unique product position by combining this network gateway functionality with logical I/O controls to form a PLC, suitable for a small machine control application with relatively simple conditional instructions.

These PLC platforms are programmed via a web server application, reducing the need for a dedicated external programming PC with installed software and drivers. An intuitive interface further reduces the training time and skills required to set up a controller to share, log, and control data points.

Connectivity in PLCs

Several versions of ControlByWeb’s PLCs have been enabled with the new cellular connectivity. These lines include the following models:

- WebRelay and WebRelay Quad (coming soon), with relays that can control equipment from a remote source.

- X-401 with 2x inputs and 2x relay outputs.

- X-410 with 4x inputs and outputs as well as up to 16x temperature sensors.

- X-412 with 4x analog inputs and relay outputs (coming soon).

Each of these model series also includes an Ethernet connection by default. Ethernet is used on initial setup to configure the wireless connection. It can also be used as a primary interface, with the wireless taking over in the event of a failure of the hard-wire system. This method, paired with a battery backup, can provide excellent resistance against power fluctuations and reduce cellular data usage, which equals lower operating costs.

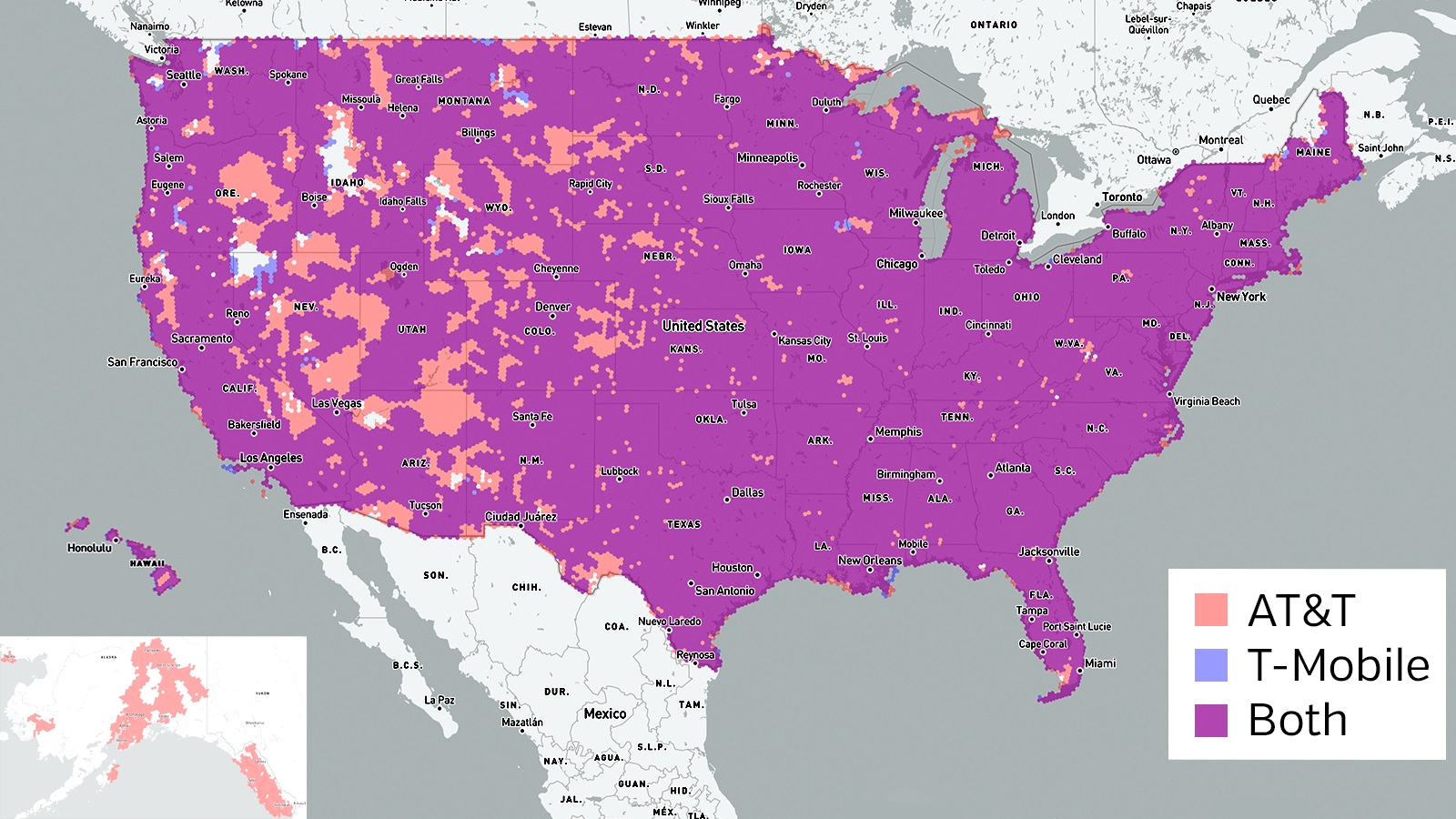

A coverage map of the US shows where two networks operate and overlap. Image used courtesy of ControlByWeb

The cellular connection is enabled by a user-supplied cell data plan which can be acquired through ControlByWeb or a separate cellular carrier. Dual-network coverage in the PLCs ensures that the most reliable connection possible is used at all times. As with any wireless connection, geographical features and location may not always allow cellular data to be reliable, so it is best to test a location before guaranteeing service.

Cloud Connection for Data Dashboards

Connectivity between the field and the cloud can be intriguing, but it’s important to ask why this application is so useful. Industry 4.0 technology is all about making data from the plant floor immediately viewable to authorized personnel for quick maintenance response times and deciding equipment use based on actual data, not assumptions.

I/O controllers with multiple forms of connectivity, like the new cellular devices from ControlByWeb, allow basic control of inputs and outputs for simple machines, while at the same time capturing that data to provide advanced analysis and a logical basis for decisions that can improve future operations.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin