Decentralized Variable Frequency Drives From Nord To Optimize Conveyance

Nord Drivesystems has expanded its existing line of variable frequency drives (VFDs) to include a decentralized option for conveyor systems. The VFD is available for use with asynchronous and synchronous motors.

Since 1965, Nord Drivesystems has manufactured drive systems for the automation industry. Today, Nord is a global supplier of drive technology with product lines ranging from AC electric motors to complex gear motors. Nord also supplies drive control products such as frequency inverters, motor starters, and variable frequency drives (VFDs). Recently, Nord released a decentralized VFD for asynchronous and synchronous motors.

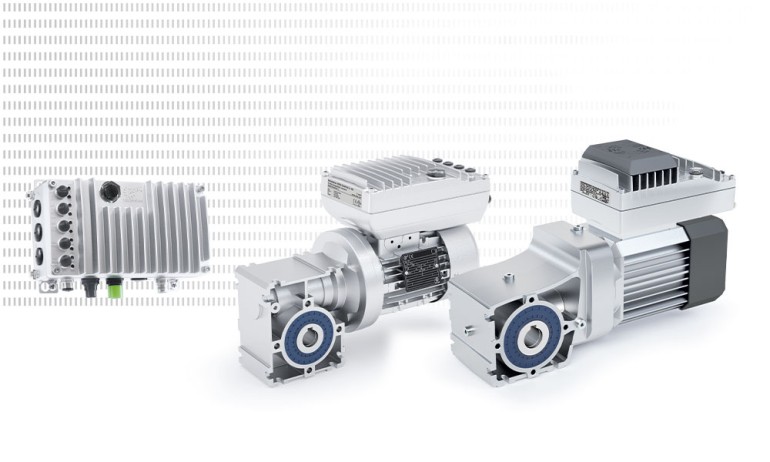

The Nordac ON/ON+ variable frequency drive for conveyor systems. Image used courtesy of Nord Drivesystems

Decentralized Devices

A common design practice is to move electrical components from a centralized location, such as an electrical cabinet, to the field. This design cuts down on cable runs and frees up space in the electrical cabinet, allowing designers to use smaller cabinets. Today, there seem to be more VFDs and servo drives that have been decentralized or a combination of devices with the drive system built into the motor. Decentralized components, however, need to withstand factory environments and be safe for technicians to work around without being injured.

The latest Nordac product line features Nordac ON for use with IE3 asynchronous motors and Nordac ON+ for use with IE5+ synchronous motors. Image used courtesy of Nord

Nordac ON/ON+ Decentralized VFDs

The latest Nordac product line from Nord is decentralized variable frequency drives (VFDs) designed for conveyor systems. Two variations are offered: Nordac ON for IE3 asynchronous motors and Nordac On+ for IE5+ synchronous motors. The Nordac VFD promises optimized operation performance and full plug-and-play capability with an integrated Ethernet interface. Both the Nordac ON and ON+ variations can be mounted on a wall or directly on the motor itself.

Each model of the Nordac series has a flexible speed range and is designed for intralogistics systems. The Nordac ON has a power range of 0.5 - 3.0 hp, and the Nordac ON+ has a power range of 0.5 - 4.0 hp. An additional 24 VDC control voltage is not required for the Nordac VFD family; only 3-phase 400 VAC is required, and the supply voltage can be daisy-chained to power multiple drives in a bus-like configuration.

The new line of Nordac VFDs brings decentralized control to conveyor applications. Image used courtesy of Adobe Stock

Drive Communications

Most drive systems today have an internal control system. The Nordac product line is no different, with an integrated PLC capable of processing data from hard-wired sensors, initiating control sequences, and communicating with other drive systems and cloud storage. Most of the popular industrial communication protocols are supported; EtherNet/IP, EtherCAT, and ProfiNet can be selected via control parameters within the drive.

Efficient Drive Solutions

Most companies are trying to reduce their carbon footprint by monitoring energy consumption within their facility or by adding smart components with multiple monitoring and diagnostic features. The Nordac VFD product has similar features, such as an energy-saving function that optimizes the motor functionally and brake management to control the motor precisely. Safety is always important when selecting devices that allow motion—the Nordac ON/ON+ offers optional features, such as safe torque off (STO) functionally and internal braking resistors.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin