Easy As 1-2-3! Cognex’s New AI-Powered Counter Increases Reliable

Cognex has released a new counting tool for the In-Sight SnAPP vision sensors. The tool performs automated quantity checks with higher accuracy and increased process efficiency.

In 2023, Cognex, the leader in industrial machine vision, introduced the In-Sight SnAPP Vision sensor, which offers a powerful automation tool for manufacturing processes. This vision sensor addresses common quality control challenges in manufacturing, including part presence, assembly issues, and part defects.

One notable feature is its ease of programmability, requiring minimal programming or vision sensor expertise. Cognex has recently enhanced the In-Sight SnAPP's functionality by integrating a new AI-powered counting tool.

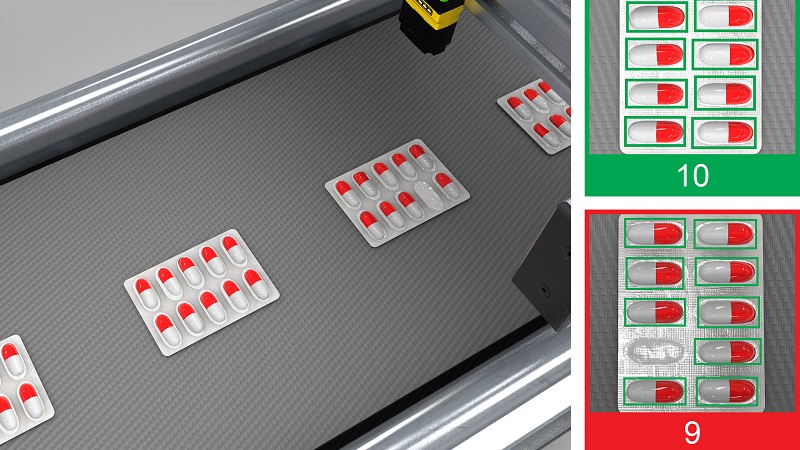

The AI-powered In-Sight SnAPP can quickly count objects of different sizes, contrasts, or shapes. Image used courtesy of Cognex

Cognex Redefines Ease of Use

Cognex's innovative software revolutionizes the process of identifying parts by eliminating the need for traditional programming. Instead, it employs a user-friendly training approach accessible through a web-based interface. This interface is compatible with any browser and enables users to train the In-Sight vision sensor from any computer. The software provides a guided experience, leading users through a series of step-by-step processes to train the sensor. This involves capturing sample images and labeling "good" and "bad" parts, enabling the AI to effectively detect anomalies and provide the desired output.

Counting Simplified

With its new AI-powered counting tool, Cognex has transformed how manufacturers can handle their automated counting tasks for quality control purposes. This innovative software allows machine builders a way to automate assembly verification and quantity checks that were previously time-consuming or prone to error. This advanced AI technology also provides an ease of use that lets more manufacturers accurately count challenging part types including objects of similar size, reflective and distorted parts, and objects with varying contrasts and shapes.

Powered by AI, the new tool reliably identifies and counts objects to ensure consistent quality control, without complex programming. Image-based training, guided setup, and embedded AI allow operators of all skill levels to quickly and effectively solve counting tasks, eliminating the need for complex setups or extensive training. “Using cutting-edge AI technology and our easy-to-use vision sensors, we’re now providing our customers with a counting solution that not only enhances accuracy and efficiency but also simplifies the user experience,” said Lavanya Manohar, Senior Vice President of Products. “We’re excited to see how this innovation will benefit manufacturers worldwide and continue making automation more accessible.”

The In-Sight SnAPP vision sensor was designed to solve common quality control tasks for automated manufacturing processes. Image used courtesy of Cognex

The In-Sight SnAPP vision sensor represents Cognex's latest advancement in user-friendly vision sensor technology, with versatile applications across various industries.

Vision Systems for Automotive and Healthcare

Cognex highlights its adaptability for use in industries such as food and beverage for product counting in final packaging to ensure all products have been packed, automotive for module counting in EV battery packs to confirm proper assembly and avoid recalls, and pharmaceutical to quickly count vaccine vials or pills in blister packs and ensure correct count.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin