Emerson Releases New Laser Welder for Specific Industrial Manufacturing Needs

What is the new laser welder machine from Emerson?

Emerson develops multiple welding solutions such as ultrasonic plastic welding, hot plate welding, thermal welding, ultrasonic metal welding. Among the several laser welding platforms meant for automotive, electronics, medical devices, appliances, textile, and packaging industries, Emerson launched a new laser welder machine, Branson GLX Micro Laser, for welding on small delicate plastic parts.

Branson GLX Micro Laser Welder

Branson GLX Micro Laser Welder is Emerson’s welding solution designed to produce high-quality medical and consumer electronics products with delicate plastic parts. The benchtop version of the welding solution holds the parts to be welded together with very low force and uses laser technology to produce clean and repeatable welds on the plastic components. The solution provides an increased output and more design options for the manufacturers. Laser welding is used to join together small pieces of different materials without any particulates.

The Branson GLX Micro Laser welding solution is used to create strong invisible welds for different plastic parts of electronic devices like earbuds, cameras, cellphones, accessories, and wearables without using adhesives or solvents.

For the medical industry, the laser welder is used for welding on delicate plastic parts like for products like patient aids, monitors, and analytical devices components. It can help manufacture drug delivery tools like insulin pends, patches, pumps, and inhalation and intravenous devices without any extra welding material. Micro-welds done by the machine can have seams as small as two millimeters.

Branson GLX Micro Laser. Image courtesy of Emerson.

Branson GLX Micro Laser runs on servo position control actuation that can perform operations at up to 200 mm/s speed. It delivers 250W of power to the weld and uses water and air cooling. Satisfying industrial standards, it can communicate over CANOpen protocol and has USB and Ethernet data interfaces.

Advanced Laser Welding Technology

Laser technology is extensively used for different welding solutions for various materials ranging from strong metal to delicate plastic. They can weld small, medium, and large parts at high speeds for high volumes. Laser technology is able to perform well-defined 3D contoured welding with precise control of melt-down weld depth.

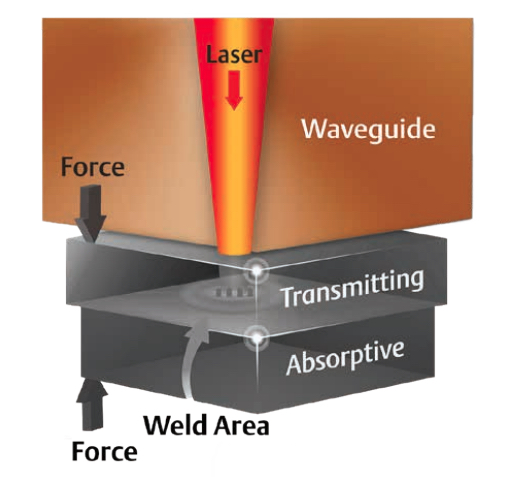

Laser emitting waveguides can weld along 3D surfaces melting the complete path at once to provide uniform weld. Image courtesy of the product brochure from Emerson.

Since laser technology does not use friction, vibration, or harsh lateral movement to bind the workpieces to be welded, no particulate is generated and the weld is smooth and almost invisible. For products like automotive tail lights that need a more transparent area, laser welding produces strong and precise results with the least opaque areas. Laser welding does not need a flat welding plane and the laser beam can be focussed along multiples axes.

Branson GLX Micro Laser uses the patented SITTIr technology for exceptional results to satisfy industry needs for delicate material welding with clamp focus as low as 1 Newton.

Simultaneous Through-Transmission Infrared (SITTIr)

The Branson GLX Micro Laser welder uses Simultaneous Through-Transmission Infrared (SITTIr®) laser welding technology to create strong welds at high speeds without leaving any marks on the workpiece. SITTIr® technology is capable of firing all lasers simultaneously thus sealing the complete weld surface by heating, melting, and bonding the components. Depending on the length and geometry of the weld surface, the technology can weld surfaces within 0.5 - 5 seconds.

The quick speed and simultaneous welding feature allow for high throughput and reliable welds. It uses fiber-optic bundles to provide light from diodes to the Waveguide, a tool that directs the laser to the target line and generates heat for the weld.

Branson GLX Micro Laser Design

The machine has a stainless steel body and components. Thus, the design is heat- and fire-resistant and can stand tough environments because of its corrosion resistance performance. The machine is highly durable and can withstand poor operating conditions.

Given the high performance and advantages of Branson GLX Micro Laser Design, the machine is set to address the industrial demand for small and intricate plastic part welding. The machine is easy to integrate with the production line and can be managed through the manufacturing execution system.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin