Emerson updates the DeltaV control software with increased compatibility

A new update for the DeltaV control system from Emerson adds connectivity, eases integration woes, and increases ROI by utilizing existing architecture.

Emerson has improved upon their DeltaV control software. The newest version, DeltaV Version 15, Feature Pack 2, adds connection capability, ultimately saving time and effort by seamlessly integrating with existing automation systems. This makes it much easier to transition from third-party control systems to an Emerson Delta Distributed Control System (DCS) than ever before.

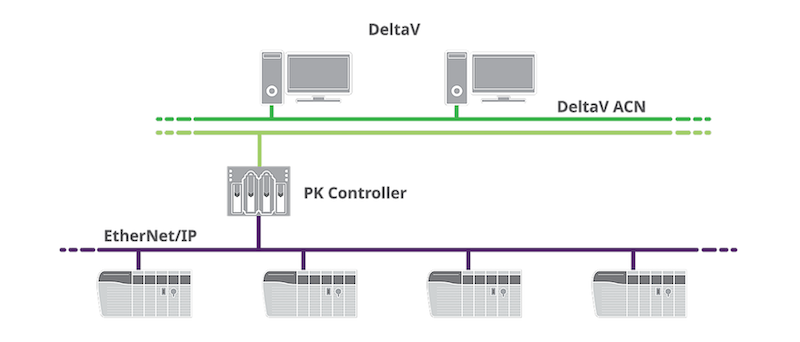

Schematic of how Delta V integrates with other systems. Image used courtesy of Emerson

Control Systems and the Need for Simplicity

The adage, “If it ain’t broke, don’t fix it,” applies to many manufacturing facilities. Many legacy data collection and control systems have plenty of life left in them–they ain’t broke. They do represent a large investment, and perhaps they are just starting to produce a return on investment (ROI). It’s hard to justify a new control system as a plant engineer.

Unfortunately, this attitude leads to a cobbled-together, bottom-up approach to new hardware. Controllers and components are only replaced when they fail. Scalability suffers as new pieces are added on, and troubleshooting becomes a literal and figurative tangle of wires.

This is where the newest Emerson DeltaV package excels. It works on top of the existing architecture rather than replacing all of the existing hardware and software. Instead of replacing, it enhances and simplifies the entire control system, making it easier to make data-driven decisions and increasing the ROI.

Version 15, Feature Pack 2

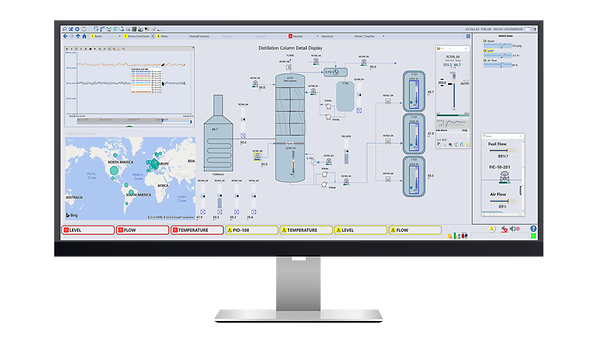

Emerson’s DeltaV Version 15, Feature Pack 2 software package adds compatibility between more third-party systems than ever before, speeding up the integration process with existing control systems. It also expands support for Ethernet devices, meaning more data can be gathered across a more diverse set of sensors, and more data-informed decisions are possible. Feature Pack 2 also plays nicely with other Emerson products, such as DeltaV Live, which helps users navigate safely between multiple displays.

Besides the ease of integration and troubleshooting, Feature Pack 2 gives the engineer more options for executing state-based logic. Depending on the situation, different states can be activated in a specific order. Safer, more reliable, more efficient operation is made possible through this flexibility in control logic.

Emerson’s DeltaV control system easily integrates with DeltaV Live, making navigation between displays and systems seamless. Image used courtesy of Emerson

Claudio Fayad, vice president of technology at Emerson’s process systems and solutions business, summed up the latest version by stating, “DeltaV Version 15, Feature Pack 2 provides users new functionality, capabilities and enhancements to further expand seamless data and I/O integration as well as applications to more easily modernize their operations, improve connectivity and collaboration, and lock in operational excellence.”

Primary Advantages for Upgrading

The newest version will add connectivity options and provide easier integration with existing hardware. This saves money and headaches: a working system can be made better rather than starting over with new hardware. Furthermore, it saves on troubleshooting time and downtime (both planned and unplanned) as data collection and control is performed on top of existing, functional systems.

In this world of data-driven decisions, new control hardware that interfaces easily with existing systems while collecting more data will benefit virtually any industry.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin