End-of-Life Considerations and the Natural Order of Machinery

Automation technologies experience an ‘end-of-life’ that must be considered by end users. Mitsubishi’s recent announcement regarding the MR-J3 servo repair program is a good example.

Nobody likes to talk about death, but everything must eventually die. Robots are no exception.

A striking and unusual art exhibit illustrated this dramatically when, back in 2016, a robot was designed to try and continuously clean up an expanding pool of hydraulic fluid until contamination finally ground it to a halt after working for several years. While not a living, biological creature, machinery eventually wears out. The decision as to when to repair and when to replace is based on a comprehensive view of the costs.

The somewhat morbid artistic installation called ‘Can’t Help Myself,’ by Sun Yuan and Peng Yu. Image used courtesy of Wikipedia Commons

End-Of-Life Planning

Keeping in mind that even the newest, most advanced machine will eventually fail, plant managers and engineers should make an end-of-life plan for large, critical, or expensive capital equipment. End-of-life planning begins the moment the machine is purchased. From day 1, a data collection plan should be in place. This should track uptime/downtime, how much time and money was invested in training personnel, estimated maintenance costs and timeline, and so on. Utility costs should also be tracked, as newer, more efficient machines will be developed later, and without an understanding of how much the existing equipment costs to operate, it will be difficult to gauge when new equipment is worth the investment.

At some point, the costs of operation and maintenance will exceed the costs of purchasing a new machine. Alternatively, service contracts, parts, and consumables will no longer be produced, meaning the machine cannot be further repaired. From there, the options are to find third-party vendors, cannibalization, or scrap.

3rd Party Vendors

If the market demand is strong enough, third parties may start producing replacement parts and consumables. Products are either licensed by the original equipment manufacturer (OEM) or the relevant patents have expired, allowing others to produce these components. If third-party vendors make components, they might be able to extend the life of the equipment a little longer. Be warned, however, that the installation of third-party components may also void any remaining warranties or service agreements.

Cannibalization

Another option for failing equipment is to take them out of service and use them for parts. Much like an automobile junkyard, one failed or obsolete machine may be able to supply parts for multiple machines to stretch their service lives. This is particularly useful for large manufacturing plants with many identical pieces of equipment running.

Cars waiting to be picked apart at a junkyard. Image used courtesy of Wikipedia Commons

To make the most of cannibalization, technicians and engineers should catalog the parts they have on hand so that valuable components can be quickly located and replaced.

However, just like automobiles, every equipment model has its weak spot, and eventually, there will be an entire machine bay, all missing the same component. At some point, there are a lot of machines with the same failed components.

Scrap and Sale

Market forces and maintenance costs eventually lead to the end of most machines. Either newer, more efficient models better meet the business needs of the plant, or the machine simply cannot be repaired economically any longer.

If the equipment is still in working order, it might be worth listing it for sale. Sometimes, the economy of scale is such that a machine will not be profitable at a larger plant, but will for a smaller plant. Also, some equipment is suitable for college or trade school use and can be donated as a tax write-off. By selling or donating to a school, this equipment may be used to create a pipeline of students to employees, offloading training time to the school.

Sometimes, there is nothing left to do but sell, or even pay, to have the machine scrapped. Depending on the specific scenario, the plant may receive a small amount of money for the metals, or it may need to pay to have a company haul it off and dispose of it in accordance with local, state, and federal laws.

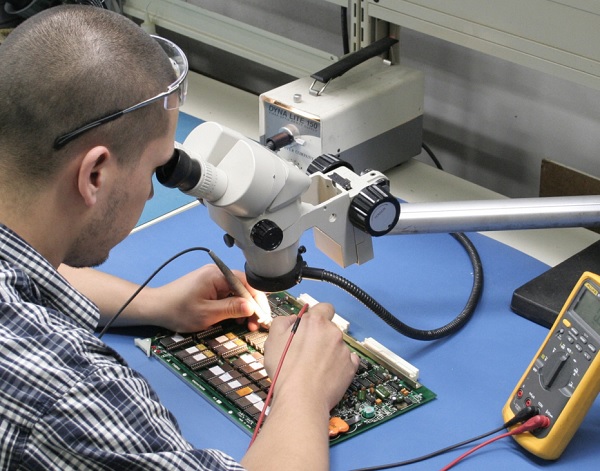

Repairing products can sometimes be worth the investment, but the costs must be calculated. Image used courtesy of Mitsubishi Electric

Mitsubishi Electric Automation’s Discounted Repair Program

Recently, Mitsubishi Electric Automation (MEA) released its Discounted Repair Program for MR-J3 servo amplifiers. These servo amplifiers have reached the ends of their service lives, and MEA is phasing them out. Rather than simply abandoning the platform entirely (as many manufacturers do), they have a discounted rate for service calls, while supplies last.

This service includes proprietary firmware programming, repairs performed by MEA-trained technicians, and one-year warranties. MEA says that this will help support customers for a little longer until they are ready to upgrade to newer systems.

Considering the Total Lifecycle of Equipment

Sometimes replacement parts, while expensive and unplanned, are the way to make the most use out of a machine. In a car, it’s easier to replace the alternator than the entire engine. However, as the cost of replacement parts begins to approach that of the payments on a new machine, or parts become hard to find, plant managers must also consider the “downtime” cost while a machine sits broken and idle. Ultimately, the decision to repair, refurbish, or replace equipment will need to account for all costs associated with the operation, including future maintenance, retraining for new equipment, software upgrades, and all other considerations.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin