FANUC Expands Its Best-Selling Robot Series to Include Three Arm Variations

FANUC has expanded its tabletop industrial robot family to feature a higher weight-payload ratio, six-axis articulation, and up to 911 mm reach.

As the “industry-leading” CNCs, robotics, and factory automation supplier, FANUC launched the lightweight and tabletop-size LR Mate robot almost 30 years ago. It has installed over 70,000 units around the world. LR Mate 200iD/14L is the new addition to this popular robot series.

FANUC LR Mate Robot Series. Video used courtesy of FANUC

The LR Mate Series’ Capabilities

FANUC’s “best-selling” LR Mate series of human arm-sized robots have been deployed in an assortment of manufacturing and service applications, including handling and processing parts in the food, automotive, e-commerce, pharmaceutical, medical device, and other industries.

To accommodate certain limited workspace and specific needs, this ten-model robot series includes cleanroom, food and beverage, and wash-proof versions. Each has various reaches and wrist speeds. These compact robots can reach higher levels of accuracy and productivity by equipping them with robot vision and force sensing functionality.

FANUC introduced the LR Mate 200iD/14L. Image used courtesy of FANUC

Furthermore, the LR Mate robots offer floor, wall, ceiling, and angle mounting options, which allow full flexibility and can be integrated directly into the machine tool.

LR Mate 200iD/14L: The Longest Reach and Highest Payload Model

The LR Mate 200iD models feature 4–14 kg wrist load capacity with standard, short, and long arm variations and integrated 24 V of direct current (VDC) power for easy end-of-arm-tool connection. These stronger and faster LR Mate robots with multiple mounting positions and slim arms are designed to be easy to operate with peripheral devices in narrow spaces.

LR Mate 200iD robots are integrated with joint axes speeds to maximize system throughput, as a calculated TCP speed of 11 m/s maximum. These robots also offer thru-arm cable options for iRVision, force sensing, Ethernet, and auxiliary axes.

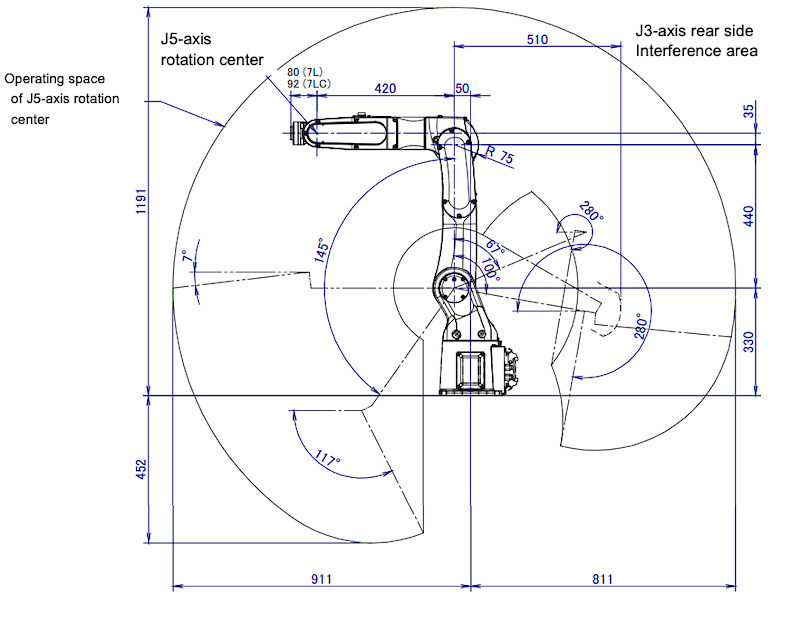

LR Mate 200iD/14L specs. Image used courtesy of FANUC [PDF]

Available at payloads of up to 14 kg, six-axis articulation, and max reaches of 911 mm, the latest LR Mate 200iD/14L model is fit for high productivity robotic handling, robotic machine tending, and robotic assembly applications.

It can contribute to a range of handling and processing applications, including an ISO Class 4 cleanroom/food-grade variant for food handling and healthcare packaging. In addition, the integrated FANUC's offline programming software ROBOGUIDE allows users to design cells, systems, and motions offline.

Industrial Applications of the LR Mate 200iD

The versatile LR Mate 200iD can be equipped in an array of industrial activities, such as assembly, dispensing, picking/packaging, arc welding, machine tending, material removal, part transfer, and more.

One of its most useful abilities in industrial facilities is robotic assembly. Utilizing six-axis LR Mate 200iD for high-speed robotic assembly of small intricate parts can provide precision without sacrificing quality. Equipped with intelligent features like 2D and 3D iRVision and force sensing, this model enhances the assembly line’s flexibility, accuracy, and productivity.

For fast-paced production, LR Mate 200iD operates on picking, sorting, packing, and inspection, with “uninterrupted” speed, reliability, accuracy, and dexterity. To lower costs and save production time, these robots are integrated with FANUC’s dedicated robotic software, coordinating multiple robots picking and packing 2,000 items per minute on a line.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin