Faster Connections! Push-In Terminal Blocks From Phoenix Contact

Wiring is a major part of the industrial automation journey. New styles of push-in connectors from Phoenix Contact promise to reduce the time and frustration associated with most traditional wiring.

Recently, Phoenix Contact, a global supplier of industrial automation components, has added a new kind of terminal block that promises to reduce wiring time by using a ‘push-in’ technology. Push-in connections remove the demand for tools during installation and promise faster upgrade speeds when specs need to be changed at a later time.

The Challenge of Cabinet Wiring

Programming PLCs and robots is only one part of automation. The other part, and probably even more common in practice, is the initial and ongoing wiring around control cabinets. These cabinets house the controllers, servo drives, and I/O blocks necessary to provide motion to the equipment. Wiring these control cabinets can be extensive, requiring hundreds if not thousands of man-hours over the lifetime of the equipment.

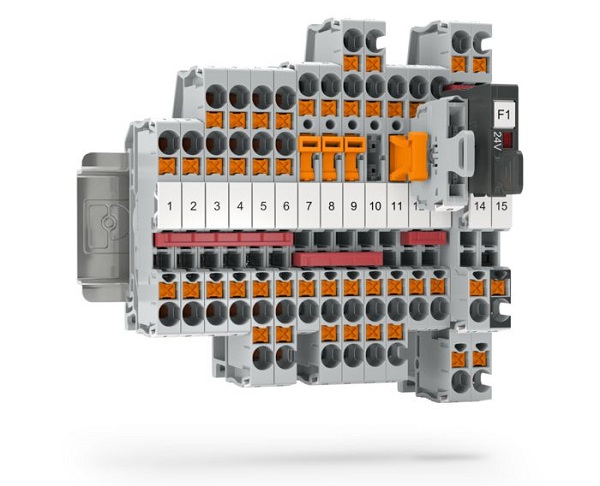

Phoenix Contact’s new Push-X modular wiring technology. Image used courtesy of Phoenix Contact

Terminal Blocks

When connecting multiple wires in a control cabinet, engineers most typically turn to terminal blocks. These blocks are made of plastic and metal and provide connection points for two or more wires. The blocks might include jumpers that can be used to create a distribution point for power or ground, stemming from only one input wire.

A single push-in plug for attaching a wire to the underlying terminal block. Image used courtesy of Phoenix Contact

Most common terminal blocks use screw terminals to fasten the wire into the block. While this is a common securing technology, it does have its flaws. If the user doesn’t fasten the screw tight enough, the screws are known to loosen over time due to vibrations. Screw heads are also known to strip, preventing the tightening and removal of the screw. Special tools are also required to fit the screws and to provide proper torque without stripping the screw heads.

Push-In Style

To help alleviate some of the issues with screw terminals, Phoenix Contact has released the XT 2.5 terminal block. This terminal block features a pretension contact spring which Phoenix Contact has titled the ‘Push-X’ Technology. The Push-X connection is on the front of the block with optional feed-through and multiple connector blocks. The XT product line also has disconnect knives and plug-in fuses that interface with the XT terminal blocks, offering a compact fuse and terminal connection solution. The XT 2.5 promises to decrease control cabinet wiring time with the easy push-in style connector. Conductors with ferrules, solid core, and stranded wires are all compatible with the Phoenix Contact terminal block.

An internal spring is used to provide constant contact between the terminal connection points and the conductor, and the spring-loaded design doesn’t require any special tools. Once the conductor is pushed into the terminal block an internal release mechanism clamps onto the conductor, making an audible ‘click’ sound. The click ensures that the conductor is firmly connected and the technician will have positive feedback that the conductor is fastened. Pressing the orange button opens the contact, allowing the conductor to be removed from the terminal block.

Robotic and automation applications always require control cabinets, and on-machine wiring is also common. Image used courtesy of Wire Cobots

Automated Wiring

Automating simple tasks allows manufacturers to produce components faster and of higher quality. Using a terminal block, such as the XT2.5, manufacturers and machine builders can automate wiring control cabinets. The XT terminal block doesn’t require two hands like similar push-in-style terminal blocks. A collaborative robot can easily be set up to push wires into the terminal blocks and once the conductor is in the correct spot, the XT terminal block will clamp down on the conductor automatically, making for a secure connection without tools or multiple hands.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin