Figure’s Multipurpose Humanoid Robot Successfully Completes Testing at BMW Plant

Figure 02, a multipurpose humanoid robot, has seen its first successful testing at BMW Group's Spartanburg plant, opening up possibilities for future humanoid robot use in an industrial setting.

Since forming a commercial agreement with BMW Group at the beginning of this year, Figure has successfully completed its first testing in a production environment. The testing took place at BMW Group’s plant in Spartanburg, South Carolina, using Figure 02, a commercially viable autonomous humanoid robot. Figure and BMW Group will continue collaborating to evaluate different methods of safely integrating humanoids into the industrial work environment.

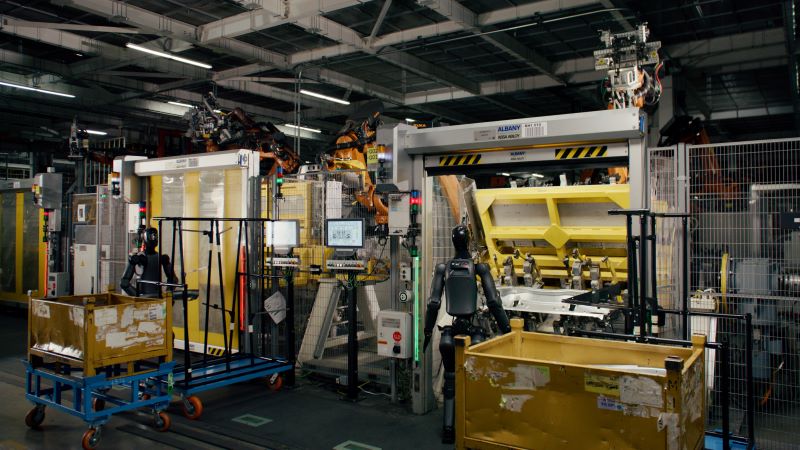

Figure 02 stands in front of a work area normally associated with human workers at BMW Group's Spartanburg, South Carolina plant. Image courtesy of BMW Group

Who Is Figure?

Figure is a California-based company known for developing advanced AI and robotic systems with a focus on creating humanoid robots. The company aims to build robots that can perform complex tasks in various environments, from industrial settings to everyday life. The company's technology seeks to address real-world challenges by integrating AI with robotics to create solutions that can assist with logistics, customer service, and more.

The Figure 02 robots were tasked with inserting sheet metal into fixtures. Image used courtesy of BMW Group

Humanoid Robots in Production

The tests at BMW Group’s Spartanburg plant using Figure’s Figure 02 robots lasted several weeks. During the testing procedure, both companies monitored the robots as they were put to work inserting metal parts into specific fixtures. The fixtures were then used to become part of the final chassis assembly. The task was particularly important because it required a high level of dexterity to be completed successfully.

During the trial run, BMW Group acquired important insights into the requirements for integrating multipurpose robots into an existing production system. This includes understanding how humanoid robots interact with the system under real-world conditions. Following the robots’ initial deployment in automobile production, BMW Group experts are working with Figure to refine the robots for future production applications and continue their development based on these findings.

Human-like hands were able to manipulate parts in an automated cell without human intervention. Image used courtesy of BMW Group

Figure 02, a “General Purpose Humanoid”

Figure’s Figure 02 robot is engineered for complete autonomy in performing tasks that replicate human dexterity, including those that require intricate and coordinated manipulation with both hands. It can manage and position complex components with high precision, down to millimeters. The human-like robot exhibits dynamic walking capabilities, effectively utilizing the design efficiencies inherent to its construction. This combination of advanced manipulation skills and efficient movement allows the robot to handle a broad spectrum of sophisticated tasks with accuracy and versatility.

Figure 02 has been designed for challenging environments where tasks are physically demanding, unsafe, or repetitive, in order to boost ergonomics and safety for workers. It offers three times the processing power of its predecessor, improved voice communication, upgraded cameras, microphones, sensors, and a high-performance battery. It even features advanced fourth-generation hands with 16 degrees of freedom each, delivering strength and object manipulation equivalent to human capabilities. The ability to mimic human movement and dexterity opens up a broad range of possibilities for the future of this budding technology.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin