GEA’s New Valve Control Tops Aim to Enhance Operational Safety

Food processing technology supplier GEA has released a new generation valve control top model to enhance control operations in industrial environments.

The T.VIS M-20 is designed to control and monitor process and clean-in-place (CIP) operations. The new valve control top will be reportedly compatible with the vast majority of technologies in all applications in the food and beverage and pharmaceutical industries.

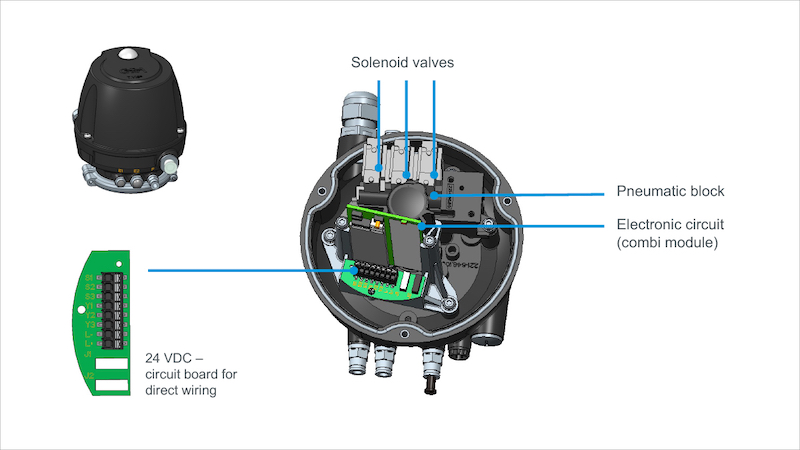

The GEA T.VIS M-20 Control Top. Image used courtesy of GEA

Food Processing Technology and Control Operations

GEA is a supplier of food processing technology around the world. First established in 1881, the company produces machinery, plants, and components for various markets.

Last year, GEA also employed 18,232 individuals across its various offices and industrial buildings in the US, South America, Africa, Oceania, and Asia. Headquartered in Düsseldorf, Germany, the company designs and produces several products and technologies, including automation and control systems, valves and pumps, emission control systems, and many others.

The hardware configuration of the GEA T.VIS M-20 Control Top. Image used courtesy of GEA

GEA has recently entered a partnership with Aker BioMarine, a Norwegian biotech company, to build the world's first plant to produce krill protein. The collaboration was firstly announced in July when the companies signed an engineering, procurement, and construction contract valued in the double-digit millions. The release of GEA’s T.VIS M-20 Control Top now fits into the group’s plans to support the industry’s rise in the adoption of plant automation technologies.

The GEA T.VIS M-20 Control Top

GEA has developed the T.VIS M-20 to provide advanced control and connectivity options that are traditionally present exclusively in premium-class control tops. According to Bernd Porath, Product Manager for Valve Automation at GEA, many industrial plants today need to run at full capacity for an extended period of time, with product changes being made very rapidly.

These actions put valves under substantial pressure surges and vibration, potentially exposing plants as a whole to higher mechanical stress.

“Our GEA T.VIS M-20 counteracts this thanks to its shock-resistant design and built-in sensor technology,” Porath explained.

In particular, the vibration and shock resistance of all its components was increased to 10 g by IEC/EN 60068-2-6 and 27, doubling up the level of the previous model. In addition, T-VIS housing technology enables high levels of protection against dust and moisture thanks to its IP69k standard. This will support operators in ensuring plant availability and quality through process controls with automatic, self-learning, and reproducible capabilities.

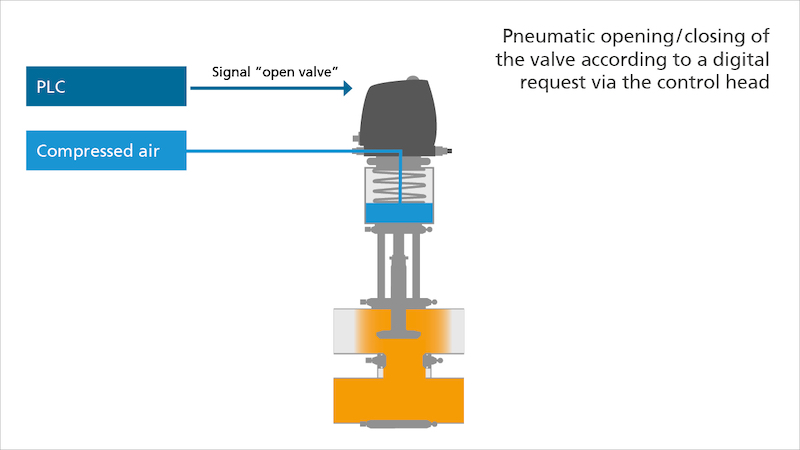

The GEA T.VIS M-20 Control Top opens and closes automatically according to a digital request via the control head. Image used courtesy of GEA

The valve top’s automatic capabilities also reportedly simplify installation and reuse of valves in the process, with several tests being conducted in field tests at Arla Foods and Uckermärker Milch.

“Our customers were astounded and very pleased,” Porath said, commenting on the test results.

The M-20 can be installed quite intuitively, according to the executive, without needing to rely on judgment or experience by the operating staff.

“We have considerably reduced the burden on operators by eliminating errors caused by different users entering different settings,” Porath added.

Moving forward, the Product Manager said GEA will continue to work on digital control tops with sophisticated automated functions and feedback options to facilitate the transition to an improved climate footprint.

What do you think about the new GEA T.VIS M-20 control top?

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin