GE’s Digital’s Proficy CSense Industrial Analytics Software Aims to Better Analyze and Collect Data

How is GE's Proficy CSense software making complex algorithms easier to navigate?

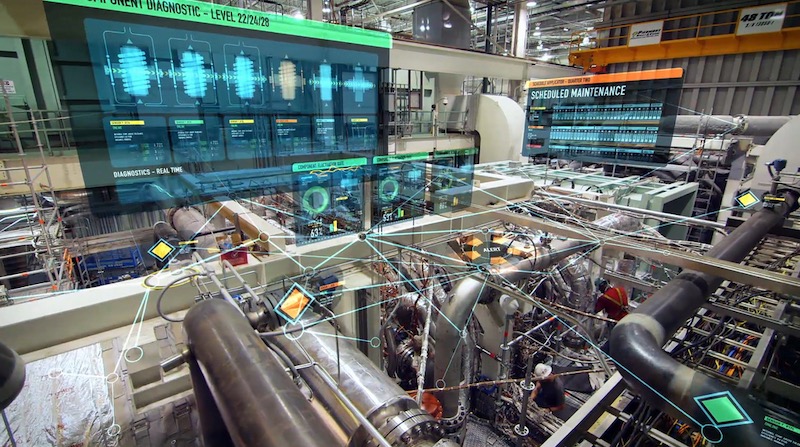

Engineers that work in industrial settings often have a lot of data to collect and analyze. Whether they are working on a motor, sensor, or any type of control system in the facility, it is crucial to have access to all of that data. There is a lot of software on the market available to help engineers analyze and collect their machine data. GE recently released new features to its industrial software to help this process.

Proficy CSense Industrial Analytics Software

Proficy CSense is part of the GE Digital software package that allows process engineers and technicians to collect and analyze data. The GE Digital package also offers an HMI/SCADA package, a historian package to collect and store data, and an operations hub to oversee the process or machine efficiency.

GE's software and new features aim to help engineers analyze and collect data. Image used courtesy of GE

By analyzing the collected data with complex algorithms, one can predict problems, improve quality, and identify root causes. The CSense software uses AI and machine learning to make complex algorithms easier to navigate. Having an efficiently running process can reduce downtime and increase profits.

Proficy CSense Utilizes Just-In-Time (JIT) Manufacturing

If it’s one thing computers are good at, it is solving complex and simple calculations. The CSense software does that by utilizing AI and machine learning. The CSense software can even use historical data to deploy calculations which can help improve operations and quality quickly. Gathering and analyzing process data quickly and efficiently may allow companies to develop quality products with less waste. GE does this by using a Just-In-Time (JIT) manufacturing process.

Just-In-Time (JIT) manufacturing is when parts are delivered to an assembly line as they are about to be installed. This style of manufacturing relies heavily on suppliers being able to get parts to the factory floor on time. Reducing downtime due to quality issues or inefficiencies may help suppliers meet the requirements of a JIT process.

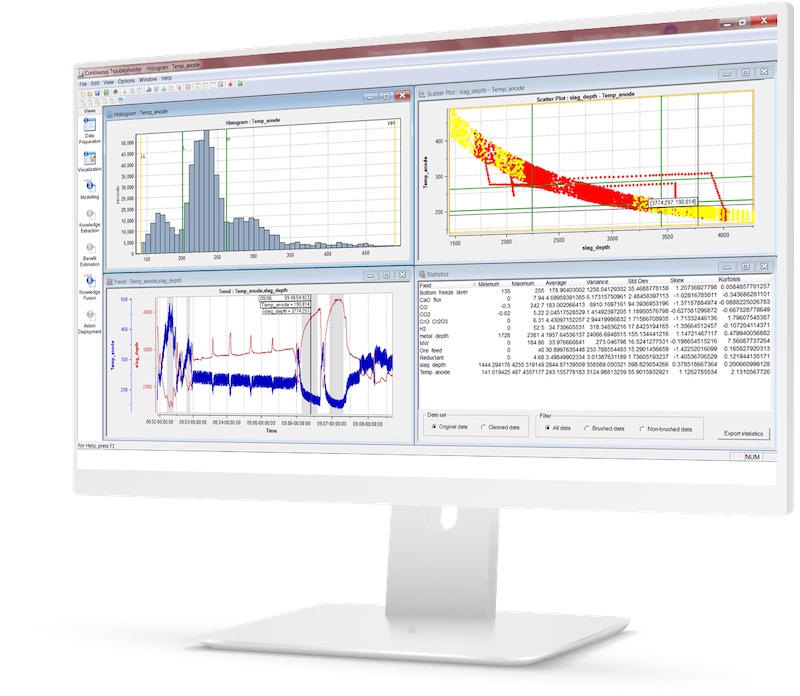

A look at the interface of the CSense software. Image used courtesy of GE

The world is requiring companies to produce products with less waste for a cleaner environment. The Proficy CSense may help companies reduce waste by analyzing the data and looking for where the product is wasted. Once the system determines where the waste occurs, engineers and technicians can eliminate or reduce that part of the process.

In addition to the processes mentioned above, GE recently added some new features to this software.

New Features

The CSense software has added new features such as PID (proportional, integral, derivative) control tuning, and OPC UA communication.

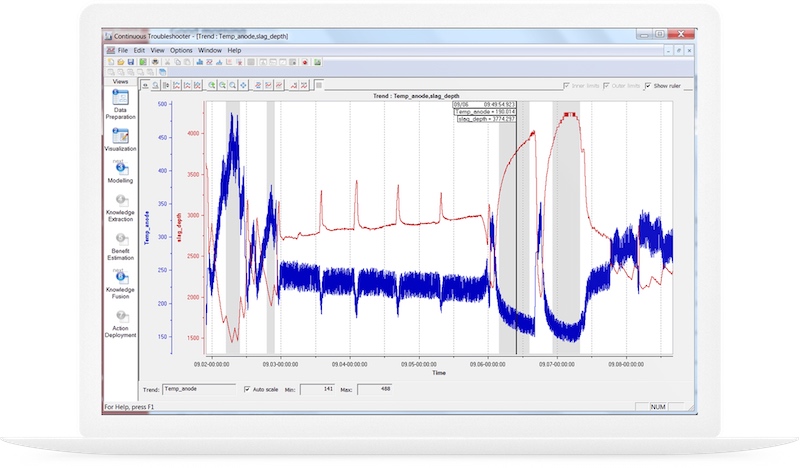

PID control is the method of driving an output towards a setpoint using at least one feedback method and limited over-shoot. This type of control is typical of temperature control or motion control. Tuning a PID loop can be very difficult and time-consuming, depending on the speed at which the system responds to changes.

The Proficy CSense software has a built-in tool that suggests the PID settings. The software will even use previously recorded data to refine the PID settings. This task would normally be very daunting for somebody to calculate by hand.

The interface of the CSense software showing analytics. Image used courtesy of GE

The OPC UA is a standard open protocol that many industrial automation manufacturers use to communicate machine data. Incorporating an OPC UA client into the software parameters can be read or written directly to the control system. This may save time and error-proof the process. With OPC UA being an open platform, most control systems already have access to or are already an OPC server.

Manufacturing happens everywhere in the world. Because of this, software that is used around the world must be flexible and adaptable. GE added four new languages to the software, including Japanese, Chinese, Russian, and French.

GE hopes these new features will allow control engineers and automation specialists to streamline their analytics in an industrial facility better. What do you think about these new updates? Let us know in the comments below.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin