Innovative Robotic Gripper Advancements Showcased at Automate 2022

The future of robotics and gripping solutions is built around creative designs, including these innovative products introduced by SCHUNK and Soft Robotics.

Innovative Gripper Solutions

Two companies, SCHUNK and Soft Robotics, have presented new innovative gripper solutions at the Automate 2022 show. SCHUNK has created a new energy-efficient gripping system that uses technology similar to the surface of a gecko’s feet. Soft Robotics has developed a gripping system designed to grab traditionally difficult-to-grip objects. The objects include soft products, particularly in the food and beverage industry, such as cupcakes or raw meat.

Companies are continuously looking to improve their automation capacity, and creative gripping can help them reach new places within the manufacturing process. Many processes are tough to automate because of the materials they work with. Inconsistent, soft, fragile, and slippery or malleable products are all difficult for traditional robotic systems to work with. SCHUNK and Soft Robotics have both managed to find new ways of dealing with difficult-to-manage products, allowing manufacturers new areas in which to expand their robotic workforce.

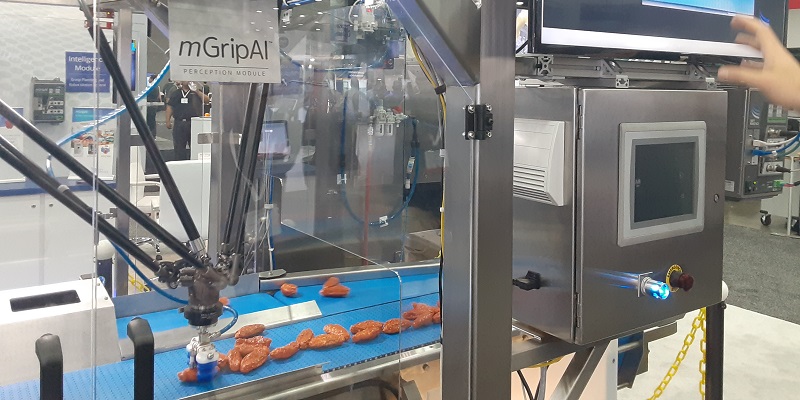

Soft Robotics’ mGripAI on a standard 6-axis robot, identifying and sorting products with a food-grade compatible system.

SCHUNK

SCHUNK has joined forces with INNOCISE, a startup company that develops reversible adhesives. The companies looked to the feet of geckos for inspiration. Geckos have many small hairs on the bottom of their feet that allow them to grip many different surfaces. The microscopic hairs are so small they can stick to the surface molecules of almost any surface. The ADHESO gripper developed by SCHUNK takes advantage of this technology by using millions of tiny polymer chains to act like those hairs on the bottom of a gecko's feet. The end result is a gripper that can grip many different surfaces without the use of external energy, whether that be pneumatic or electrical.

SCHUNK has introduced a gripping solution which, with a slight twist to the wrist joint, can grip a wide variety of objects with no external control input.

The gripping system is a new product for both INNOCISE and SCHUNK. From their work they have gathered international support for this new greener, more efficient technology. The gripper shows promise for creating a more sustainable future in manufacturing. Products that can perform tasks without the use of external energy have the potential to save a significant amount of energy over time.

Soft Robotics

Soft Robotics has developed a new gripper that is capable of working with different food handling processes. The gripper is called the mGripAI™ and uses 3D vision, soft grasping, and artificial intelligence (AI) software, simultaneously to make a robust gripping system. The pandemic has shown how dependent the food industry is on human labor and Soft Robotics has helped to develop a system that can replace the need for human labor for some pick and place applications in the food industry.

Soft Robotics’ mGripAI, attached to the end of a delta robot, demonstrates the handling of (simulated) raw food products.

The gripping solution provides a first ever system that is capable of bin picking in the food industry. With the use of AI, 3D vision, and soft grasping the gripper has hands, eyes, and brains capable of handling the difficult task of food handling and packaging. It is a IP69K rated food-grade gripper for safe product handling, and was developed with intelligent robot motion control for maximum throughput. The gripper uses 3D vision to achieve real-time object tracking for maximum pick accuracy. With embedded object understanding, downstream plant processes are able to anticipate what will be coming down the line. This allows them to achieve a more efficient use of resources.

Summary

Robots have become more ubiquitous throughout most industries, and adoption is still increasing. The food industry traditionally has difficulties with soft, or irregular products when it came to automating. Soft Robotics has managed to create mGripAI™ a system capable of automating different food packaging processes. Other industries with fragile and difficult to grip products have also been helped with the use of SCHUNK’s new ADHESO gripper.

The future of robotics and gripping solutions is built around creative applications, just like these, which tackle some of the more unique products and industries.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin