Interroll Unveils New Ultra Hygienic Conveyor for the Poultry Industry

Hygienic treatment is critical in manufacturing processes for food products. Interroll’s new UHT conveyor module reduces the amount of debris and germs produced from automated cutting operations.

The Interroll Group (Interroll) specializes in the provision of material handling solutions for airports, express and postal services, e-commerce, as well as automotive, food & beverage, fashion, and other industries. In May 2022, the company announced the arrival of a new piece of cutting-edge technology for automated material handling processes. Interroll’s new Ultra Hygienic Transfer (UHT) conveyor module is intended to help customers in the poultry meat processing industry minimize the risk of contamination. The conveyor module has a hygienic product design with the ability to reduce the number of meat particles that end up on existing conveyor systems after trimming (by 85–90%).

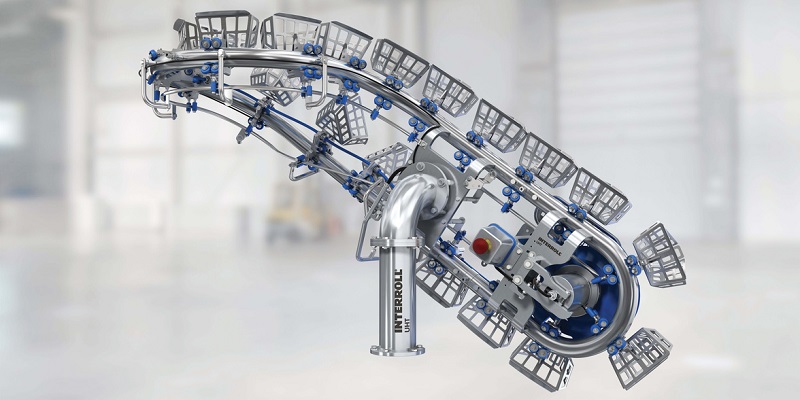

Interroll’s new UHT for the conveyance of food products. Image used courtesy of Interroll

Automation in Food and Beverage Industries

Food manufacturing and processing technology can be used in a variety of ways, from cutting, dispensing, packaging, or casing of food, feed placement, pick-and-placing products into containers, to sorting. Safety, as well as hygiene, are very important when it comes to primary food handling whether it be by humans or robots. To meet safety and hygiene requirements, robots need to be able to work alongside humans without the risk of collision, be easy to clean, and, use food-grade lubricants. The importance of food-grade lubricants cannot be understated. They ensure that robotic machinery works as efficiently as possible while ensuring ingestible food, beverage, and even pharmaceutical items do not become contaminated upon incidental contact.

Collaborative robots and other technology that are employed in the food and beverage industry must be able to be cleaned easily without incurring damage. Interroll’s UHT features a robust, hygienic design with an ingress protection (IP) rating of IP69K. This rating protects against the ingress of dust and high temperature, high-pressure water.

Improving Hygiene and Ensuring Quality Control

Different cuts of poultry meat are ferried along in a circular conveyor process. The meat is transported in stainless steel screen baskets which are then tipped onto an existing conveyor belt. As well as reducing food waste, Interroll says that measurements at test customers have shown a significant reduction in germ load of the processed meat products compared to when traditional chutes are used.

Informational overview by Interroll. Video used courtesy of Interroll

Operators working within the poultry industry can benefit from shorter cleaning times and lower water consumption. Two spray bars clean the baskets using water and disinfection, and a third spray bar cleans the basket rollers. All materials used for the UTH conveyor module are food-grade and follow EHEDG design rules.

In addition to maintaining hygiene standards, Interroll says that the separation of goods such as poultry breast caps or wings can be useful when considering quality control. The company says that the UTH can ensure that goods remain identifiable along the entire process chain. This could be achieved with the use of sensor technology coupled with goods management systems.

In a recent news release, the System Innovation Project Manager at Interroll, Dr. Stephan Kronholz, commented "The subsequently packaged end product, such as the breast cap, can then be assigned to the original product by appropriate solutions from our customers, the system integrators. This is an important prerequisite for enabling quality control along the entire supply and processing chain in the hygiene environment.”

Interroll’s conveyor module does not require sensor technology and can be installed between the upstream cutting machines and the downstream conveyor belts as a stand-alone solution. All the module requires is a power connection for the integrated drum motor.

The UTH was designed by engineers at Interroll Innovation GmbH and is now available on the market.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin