Introducing Beijer Electronics’ New, Codesys-Based Motion Controller

Beijer Electronics has expanded its existing line of Nexto Xpress controllers with the addition of the BCS-XP350. The XP350 is specifically designed for controlling single-axis and multi-axis applications with onboard I/O.

Beijer Electronics is a producer of various automation components, including HMIs, industrial PCs, PLC systems, I/O products, and servo motion controllers. The company’s newest product is the BCS-XP350 motion controller, part of the Nexto Xpress compact modular control systems family.

Beijer Electronics’ new BCS-XP350 Codesys-based motion controller. Image used courtesy of Beijer Electronics

Motion Controller vs PLC

A motion controller is very similar to a PLC. They both have onboard I/O and a programming interface. The difference is that a motion controller is designed to handle only the motion of one or more axes along with a small handful of I/O, not large equipment with hundreds/thousands of I/O points. If your application is small enough and the main focus of the automation is the servo motor, then you might look at using a motion controller such as the BCS-XP350 instead of a full PLC.

BCS-XP350 Codesys-Based Motion Controller

The BCS-XP350 is a compact, high-speed motion controller with onboard I/O and industrial communication capability over Ethernet. Offering high-precision motion control is often required for packaging equipment, assembly lines, or other equipment where users want to offload the motion control logic to another device.

The XP350 comes fully equipped with 16 digital inputs, four of which are high-speed inputs, 16 digital outputs, four of which are high-speed, five analog inputs, and two resistance temperature inputs. The four high-speed inputs and outputs can be used for high-speed counters, pulse train outputs, or pulse width modulation outputs. This level of I/O provides a solid base for many industrial applications, so an additional PLC may not be required.

The BCS-XP350 motion controller is designed to deliver high-precision motion control to industrial applications. Image used courtesy of Beijer Electronics

Communication Capabilities

For communications, the XP350 is fully equipped with a single Ethernet port and supports Ethernet TCP/IP, a serial port for RS-485 communications, a USB port, and a CAN interface. CANOpen Master protocol, ProfiNet, Ethernet/IP, EtherCat, and Modbus TCP are all supported industrial protocols over the provided Ethernet port. An optional wireless addition is possible through the external accessory USB port, and users can take advantage of either WiFi or cellular protocols.

With the XP350 being part of the Nexto product family, the communications port can utilize nonindustrial protocols such as OPC UA, a standardized open-source communication protocol. Other protocols are also supported, including HTTP, ProfiNet, Ethernet/IP, SNTP Client, SNMP Agent, and MQTT client. These nonindustrial protocols allow for remote data collection, edge integration, and communication to cloud-based applications.

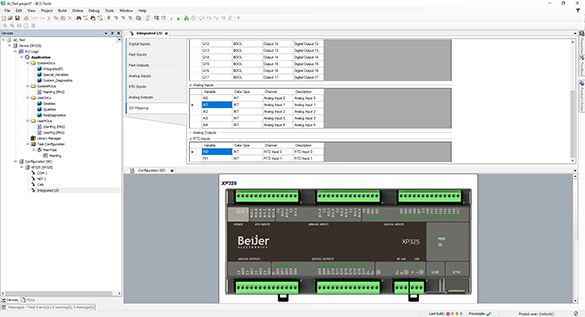

A look at Beijer Electronics’ BCS Tools programming software being used with a Nexto Xpress compact controller. Image used courtesy of Beijer Electronics

Motion Control Profiles and Programming

Simple motion applications can often be executed with digital inputs and outputs, but when you get into complex coordinated motion profiles, you need to use a motion controller. The XP350 and the PLCopen motion control function blocks allow end users to control a single axis or synchronize multiple axes. Up to three servo axes can be synchronized with one XP350 while maintaining an 8 ms scan time.

The XP350 is the first motion controller fully integrated into Beijer Electronics’ BCS Tools programming software. The software includes an integrated device configurator, which can be used to configure the new XP350. It enables users to develop, test, debug, and monitor automation programs in the popular Codesys 3.5 IEC 611312-3 programming languages. Pre-programmed function blocks, such as single-axis control or multi-axis synchronized motion blocks, are also included to reduce commissioning time.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin