Introducing Smart Skin for Robots, Data Transmission via LEDs, and Other Developments

Researchers are developing technologies that could impact automation across industries, including smart robotic skin, data transferring light, undersea seismo-acoustic imaging, and improved 3D-printed concrete.

In the rapidly advancing landscape of technology, researchers are developing innovative projects aimed at impacting automation across industries. This article will delve into the pioneering technologies currently being developed by researchers at Fraunhofer, a prominent research organization headquartered in Germany, and the School of Engineering and Applied Science at the University of Virginia.

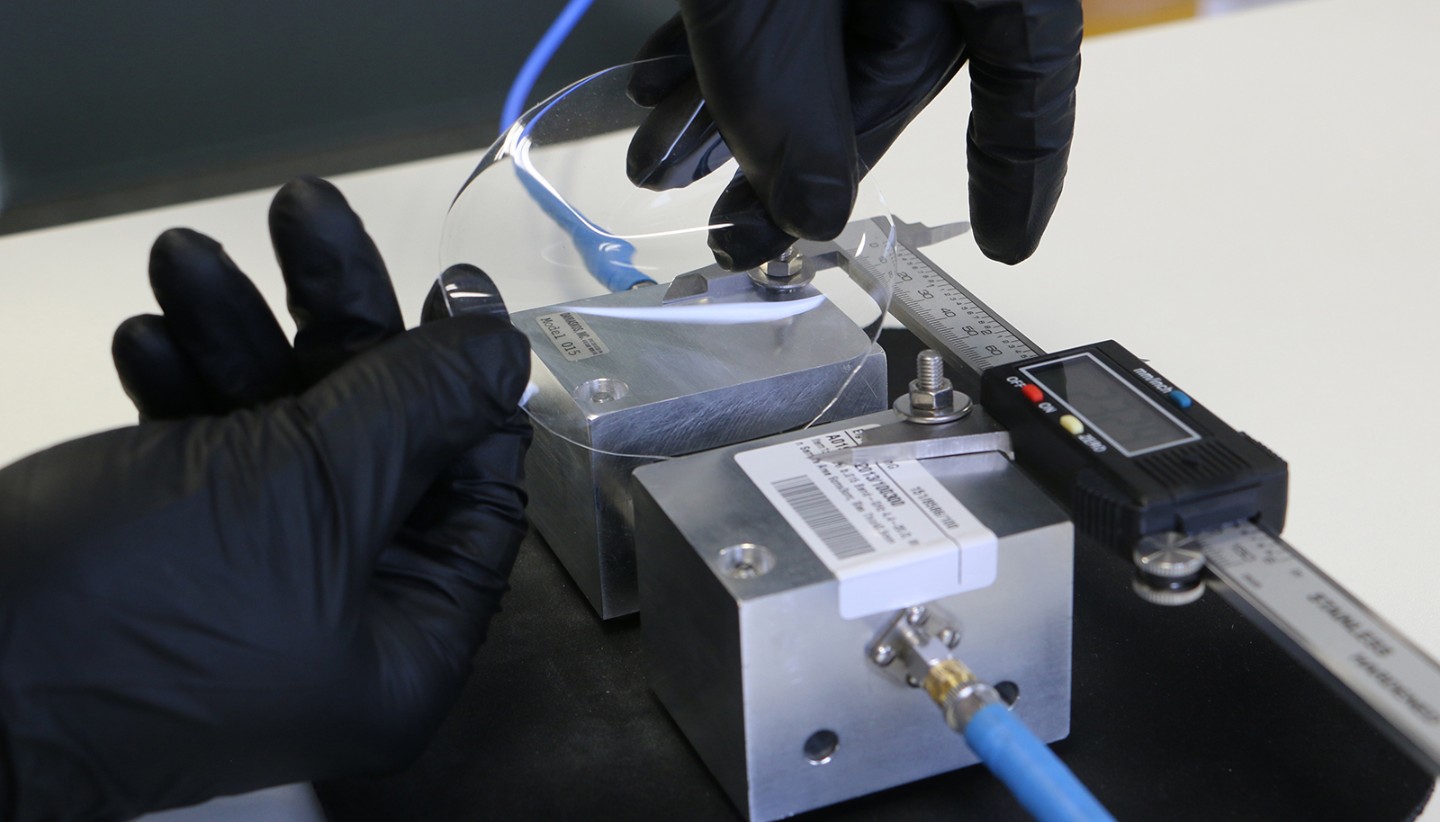

Narrow-band measurement of the loss agent of a polymer. Image used courtesy of Fraunhofer

Robots With Intelligent Skin

Given the increasing prevalence of robots in manufacturing and the automation of daily operations, the physical interaction between humans and robots has become routine. As a result, ensuring worker safety is of paramount importance and requires a multifaceted approach. Consequently, Fraunhofer has become a participant in the European Union’s Flexible IntelligenT NEarfield Sensing Skins (FITNESS) project. The primary objective of this project is to enhance the daily interactions between humans and machines through the utilization of a flexible, stretchable metasurface antenna.

This metasurface antenna will emit surface waves and effectively scan the near-field environment, surpassing the capabilities of conventional antennas. These antennas are designed to be integrated into a film-like substrate that can easily adapt to a robot's contours and allow the robot to move as designed, creating a "smart skin." These skins could help robots interact more accurately with their human counterparts. The new skin isn't just applicable to the manufacturing industry, but could also play a key role in medical engineering.

Fraunhofer’s ceiling module with built-in LEDs for transmitting data. Image used courtesy of Fraunhofer

LiFi Over Wifi: Fraunhofer’s LINCNET Project

All the buzz in the automation world seems to be linked to Industry 4.0 and getting as many machines as possible directly connected to a secure network. So what do we do when we have equipment that has to be movable as needed in their respective setting, such as X-rays and ultrasounds used in hospital settings? With the Fraunhofer LiFi-enabled 5G for INdustrial and MediCal NETworks (LINCNET) project, researchers are developing a light that can transmit data to machines and robots. This light will combine electrical networks with 5G mobile networks to create a low-cost wireless network that emits lower electromagnetic emissions.

Fraunhofer is working on integrating 5G networks with optical wireless communication to maximize wireless network efficiency. The project involves repurposing the existing electrical infrastructure to centralize data in a module located in the ceiling of each room. Data is then transmitted from the ceiling to the designated device using pulsing LEDs. This approach enables data transmission at speeds of up to 1 GB per second, with latency under 2 ms, and provides immunity to interference from other wireless signals or radiation.

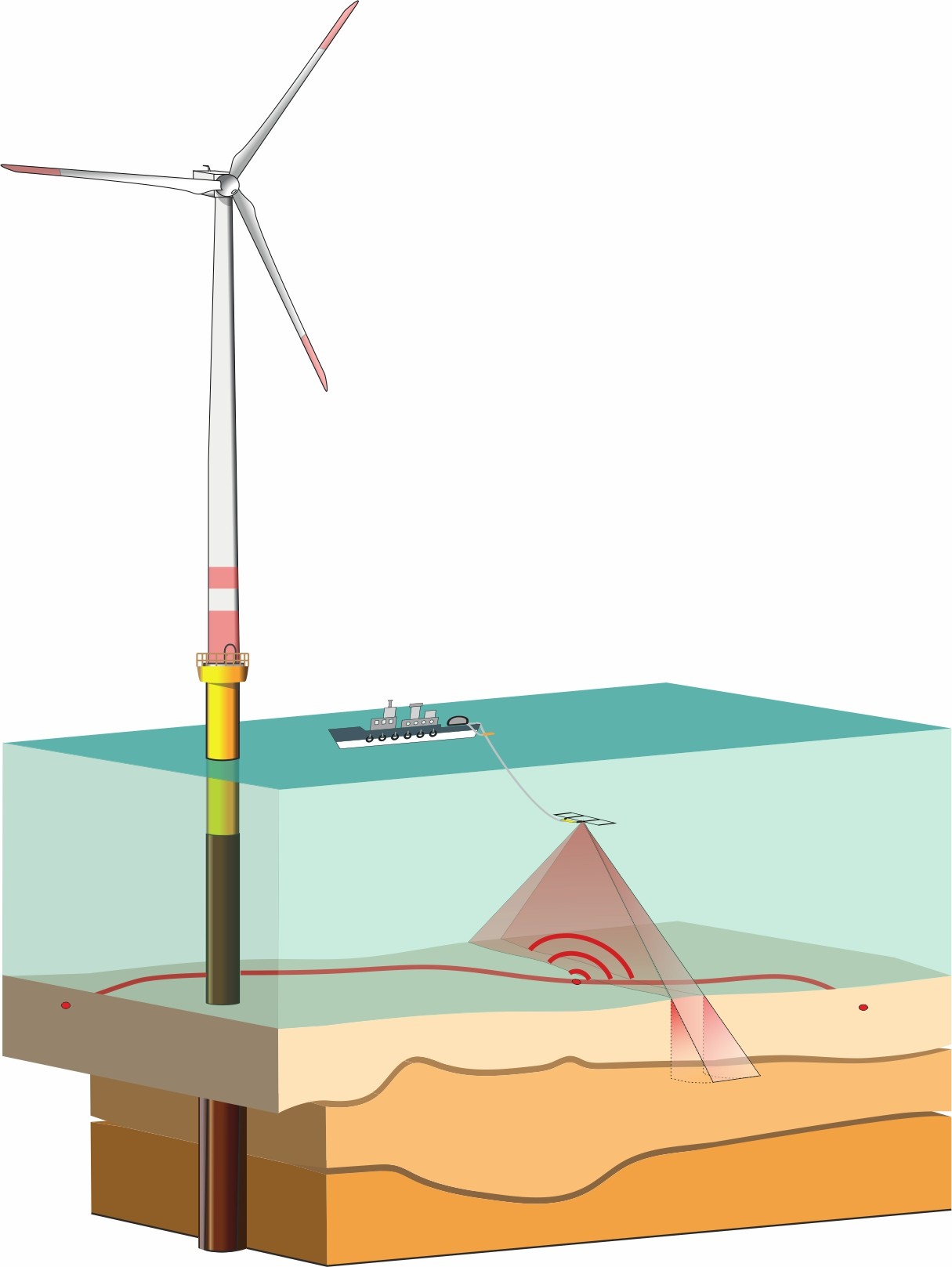

Data acquisition can be located around 10 m above the seabed with the SASACD project. Image used courtesy of Fraunhofer

Under the Sea: SASACD Project

Germany is planning to boost its offshore wind energy production by 30 GW by 2030. As a result, there is a need for swift and efficient monitoring and surveying of undersea cable routes to comply with rigorous requirements for laying these cables. These requirements are in place to ensure proper cable installation and to protect existing infrastructure from any potential damage. Current survey methods rely on costly acoustic or magnetic tools, which have shown reliability issues. Additionally, these methods require the cables to be switched off before they can be surveyed.

Fraunhofer’s Seismo-Acoustic Synthetic Aperture Cable Detection (SASACD) project aims to develop a seismo-acoustic imaging method, in collaboration with partners, for precise offshore cable detection with an accuracy of a few decimeters. This method is designed to locate cables with a diameter of 25 centimeters or more without the need for shutting off the cables prior to surveying. It has the potential to streamline maintenance operations by enabling more effective planning.

Special-made 3D printer layering concrete mixture containing cellulose nanofibrils. Image used courtesy of the University of Virginia

Eco-Friendly 3D Printed Concrete

Researchers at the University of Virginia School of Engineering and Applied Science are working on enhancing the construction of 3D-printed concrete by incorporating cellulose nanofibrils. This plant-based material shows promise in improving the resilience and environmental sustainability of 3D printing construction methods. Ensuring that the concrete mixture maintains proper flowability during the printing process while also achieving the necessary material properties for structural integrity in construction is a key focus of this work.

The research team has conducted experiments with nanofibrils and discovered that adding at least 0.3% cellulose nanofibrils to the concrete mixture improved flow performance. Furthermore, hardened samples exhibited enhanced material bonding and structural integrity, demonstrating resilience in pulling, bending, and compression tests.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin