It’s a Wrap: Wulftec and Prime Robotics Integrate to Transform Order Fulfillment

How do you revolutionize automated order fulfillment? Wulftec and Prime Robotics believe harmonizing pallet management and stretch wrapping technologies provides a solution.

Prime Robotics, Inc. (PR) and Wulftec International, Inc. (Wulftec) announced their entry into a partnership focusing on integrating PR’s pallet management solution with Wulftec’s stretch wrapping technology. Both PR and Wulftec aim to increase customer satisfaction by providing an end-to-end automation solution that can elevate the existing capabilities of automated stretch wrapping and pallet management systems in order fulfillment facilities.

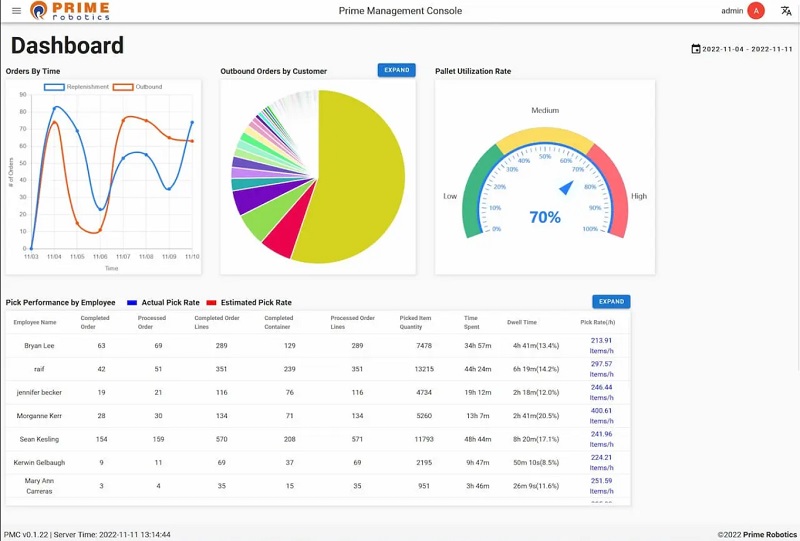

PR software users can use the Prime Management Console to keep track of orders, access important data, monitor operational efficiency, and make informed decisions. Image used courtesy of PR

Stretch Wrapping Market and Process

According to a report by Future Market Insights, the size of the stretch wrapping market totaled $4.1 billion in 2022 and is projected to reach $7.1 million at a compound annual growth rate of 5.6%.

Stretch wrapping is a standard packing method used in order fulfillment for securing items to pallets for reliable storage and shipment. This technique involves wrapping the cargo with a plastic sheet, protecting items from damage, and providing stability when shifting, handling, and shipping items. Three crucial processes are involved in the stretch wrapping process:

- Loading. Prepping the load for wrapping involves carefully positioning goods on pallets to maximize stability and reduce the chance of damage in transit.

- Wrapping. A machine or automated system is used to wrap the load tightly with a shrink-wrap plastic film enclosing and securing the load.

- Shrinking. In some circumstances, heat is applied to shrink the film to secure the load further.

Automation-enhanced Stretch Wrapping

Automation is transforming stretch-wrapping operations in warehouses and distribution centers, resulting in significant efficiency gains. High-volume operations especially require fast, reliable, and consistent wrapping solutions. Automated wrapping technology will outperform manual approaches in almost every regard.

Automating the process takes manual labor and human error out of the equation and allows operators to concentrate on other high-value, low-risk tasks. This reduces the likelihood of injuries associated with physical wrapping and improves overall operational safety. Additionally, automation guarantees correct wrapping tension and other critical parameters.

Along with streamlining order fulfillment, combining automated stretch wrapping with logistics/warehouse management eliminates manual involvement and optimizes workflow for greater operational efficiency. Although the initial expense of automating processes can be high, the long-term advantages are likely to be worth the risk and financial investment over time. Benefits include reduced labor costs, efficient material use, better quality outcomes, and a solid return on investment. Over the last several decades it has become clear automation is fundamental to the cost-effective operation of packaging, shipping, and order fulfillment facilities.

Revolutionizing Order Fulfillment Robotically

PR offers a versatile software solution for more effective warehouse operations. The core Robot Control System offers artificial intelligence capabilities like Smart Stowing and task scheduling to increase efficiency as operations scale, and it supports both on-premises and cloud deployments.

The Prime Management Console enables user settings, real-time order control, and flexible system customization. Its intuitive dashboard organizes critical information clearly which aids decision-making support. Thanks to the Universal Warehouse API's global integration capabilities and the Workflow Builder's customized workflows, the solution adapts to various business requirements seamlessly. The reporting function keeps track of crucial parameters to guarantee ongoing operational improvement. This network of tools lays the groundwork for contemporary, intelligent warehousing operations.

Wulftec provides an overview of one of its fully automated stretch wrapping systems, WCRT-CRW. Video used courtesy of Wulftec

Wulftec’s WCRT-CRW stretch wrapping system provides an impressive 164 in. diameter rotary arm that revolves at 17 revolutions per minute. The clamp area features a hydraulic downender and pivoting upender for loading and unloading. A 120 in. hydraulic cradle is capable of lifting loads up to 10,000 lbs and a V-shaped conveyor with a capacity of 8,500 lbs.

All About Reaching the Customer

Leveraging each company’s technical and software-based expertise, Wulftec and PR set out to transform order fulfillment by harmonizing stretch wrapping and pallet management. The logical integration and collaboration of their innovative technologies offer warehousers, distributors, and manufacturers a better chance of getting customer orders wrapped and out the door with speed and precision.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin