Keyence Releases VS Series System With Integrated AI for Vision-Guided Robotics

The new 2d vision-guided robotics system from Keyence has built-in AI and the latest imaging technology to suit advanced operations. The system can be used with fixed and on-hand cameras.

Machine builders have been putting cameras on robots for many years — adding a camera allows for precise picking and part inspection in one operation. Most of the time, the camera chosen for the application is designed for mounting on a robot, and thus, the cable management alongside the robot is messy. Additionally, the robot’s inspection position is fixed because of the camera’s fixed field of view.

Recently, Keyence, well-known in the automation industry for its vision and sensor products, released the VS Series vision system. This system features fixed and on-hand camera capabilities and the ability to change the camera’s field of view automatically.

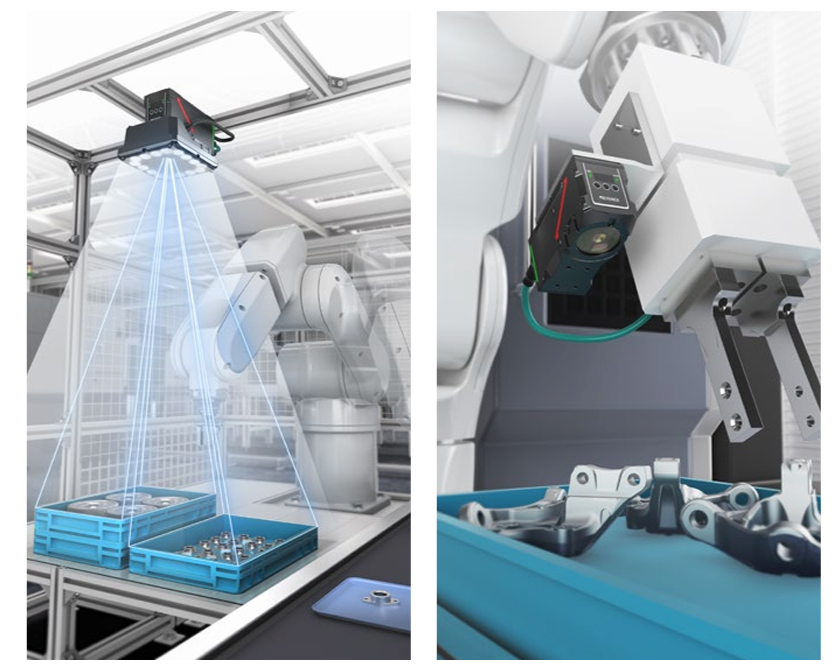

The VS Series vision system with integrated AI can be used for both fixed (left) and on-hand (right) cameras. Image used courtesy of Keyence

VS Series Vision System

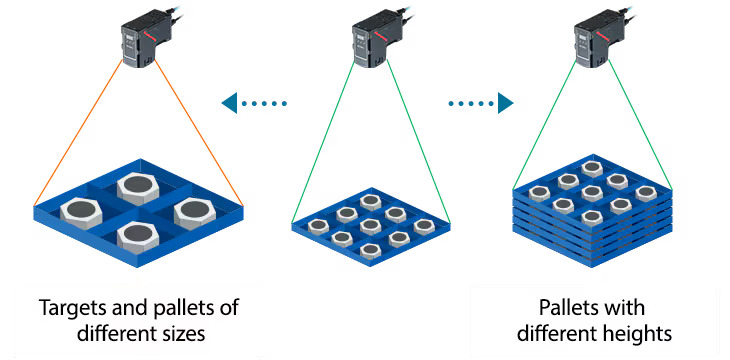

The VS Series vision system supports three camera models: the VS-L, VS-S, and VS-C. Both the VS-L and the VS-S have fixed lenses, with the VS-L capable of standard zoom and the VS-S capable of short-range zoom. Both models have auto-focusing, which enables robot inspection at various heights or parts of different sizes. The VS-C model is designed for on-hand use. It can be equipped with virtually any of Keyence’s C-Mount lenses. Auto zoom and autofocus features are not included in the custom lens.

All three models utilize internal robot communication wiring, which reduces cable breakage and the number of cables required to run alongside the robot arm. Keyence also sells ring lights, bar lights, backlights, coaxial lights, dome lights, and spotlights that can be paired with the VS vision system.

Vision Search Tools

Most vision systems have a search tool. The system is taught an image pattern, and upon inspection, the processor searches the image for a similar pattern. This tool is useful for part detection or defect detection and part location. The caveat to a search tool is that it often requires very clean images and can take longer to process, especially with larger images.

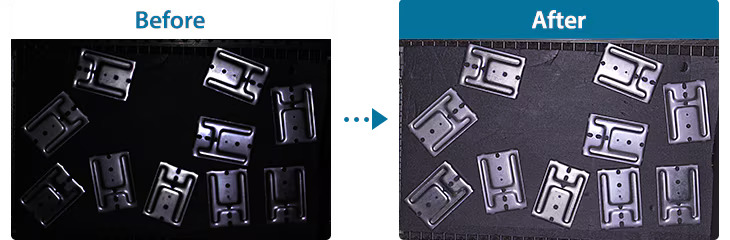

Keyence’s VS Series vision system utilizes ShapeTrax 3A, advertised as a stable, high-speed search tool. The ShapeTrax inspection tool can remove noise from an image to search for the targeted pattern. Parameters for the ShapeTrax can be automatically set and optimized, reducing the need to understand complex vision parameters.

With Keyence’s ZoomTrax technology, a camera’s field of view can change automatically, without changing lenses, to image pallets of different sizes and heights. Image used courtesy of Keyence

Vision-Guidance and Difference Checking

Vision systems are often used to check for different features of a part. This system can be useful when a robot needs to pick one type of part out of a bin of different parts. With the VS vision system, users can configure the robot to look for specific part features and the location of that part. The results can contain the location of the part, and the robot will be able to pick the detected part accurately. Position detection can also take place with barcode reading or character reading. This reduces the number of devices required for an application. The robot can verify the barcode and determine the part location using one device and one inspection.

Image Filters

Imaging post-processing allows a vision programmer the ability to clean the image or remove noise for a more reliable inspection. The VS Series vision system comes with 22 digital image filters that can drastically change the image for inspection. These filters are useful when detecting part defects such as dents or scratches.

The VS vision system utilizes advanced imaging technology to enable consistent and well-illuminated image capture over a wide field of view. Image used courtesy of Keyence

Vision-Guided Robotics

By adding a vision system to a robot, you essentially give the robot eyes; you are no longer required to locate the part accurately with fixtures. The robot can now see the part and move to it. You also allow the robot to make decisions about the part. If the part has a defect or the barcode can’t be read, the robot can decide to reject the part or place the part in a different location. The VS Series vision system provides a vision solution designed to work on a robot or in a fixed location and can provide a robot with the required data to pick parts with little previous vision knowledge.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin