Manage 24-volt DC Applications with the Weidmüller maxGUARD-ELM-18

The maxGUARD-ELM-18 system from Weidmüller protects systems from excessive voltage or amperage, prolonging the life of critical industrial equipment.

Weidmüller has recently introduced the maxGUARD-ELM-18 component, explicitly designed to manage industrial applications that require 24-volt DC. This new component aims to provide efficient and reliable solutions for industrial operations that rely on this specific voltage requirement.

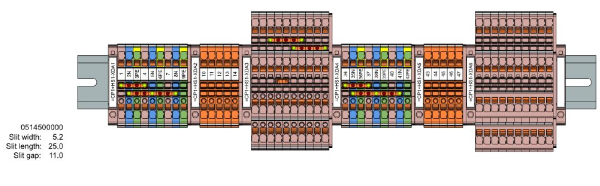

An image of the maxGUARD 24-volt distribution system. Image used courtesy of Weidmüller

Efficient operations of control systems and machinery depend on the consistent supply of controlled voltage and amperage to the machines. While a 24-volt DC is less likely to produce an electrical arc, carries minimal current, and is less susceptible to interference, monitoring the continuously supplied loads is crucial.

Failure to monitor and control the voltage or amperage could result in malfunctioning 24-volt components, possibly necessitating their replacement or causing a system failure.

The maxGUARD system, consisting of terminal blocks, is critical in monitoring loads in a 24-volt DC distribution system. Weidmüller’s maxGUARD components monitor loads effectively and provide potential distribution, thus simplifying the installation processes, reducing the risk of failures, and minimizing space requirements due to their compact size.

Features and Specifications

MaxGUARD provides advanced load monitoring functionality, setting it apart from traditional fuses. This innovative component promptly detects overloads, short circuits, and other irregular conditions, offering real-time diagnostic capabilities. Identifying potential issues early helps prevent unexpected downtime and enhances the system's reliability. Moreover, MaxGUARD enables selective tripping, allowing users to isolate only the faulty circuit while maintaining the operation of the rest of the system. This feature is particularly critical in intricate setups with multiple loads connected to the same power supply.

The maxGUARD system is a high-capacity load protection module capable of handling up to 18 amps, making it one of the most robust and powerful units available. Its impressive capability allows it to manage various 24-volt tasks encountered in industrial settings effectively. This device is particularly well-suited for applications involving high-amperage components such as DC motors.

In addition to its substantial load capacity, the maxGUARD system has exceptional durability, reinforced by its ability to operate at temperatures up to +70 degrees Celsius. Furthermore, it holds an ATEX certification, underscoring its suitability for use in potentially hazardous environments. This certification is essential for industries such as oil and gas, chemical, mining, pharmaceuticals, and food processing, where adherence to rigorous safety standards is paramount. The maxGUARD component also meets surge protection specifications and complies with the UL 2367 semiconductor standard, ensuring reliable protection for electronic devices against power surges.

An example of a DIN rail configuration via Weidmüller’s software. Image used courtesy of Weidmüller

Support

Weidmüller goes the extra mile to assist its customers with configuring load monitoring modules. Through the Weidmüller Configurator, a digital engineering client, customers can select from all Weidmüller components and customize their DIN rail according to their specific needs. This process can be done independently or with the support of their local sales contact. This innovative approach opens up many assembly options, from paperless production to automated manufacturing. The Weidmüller Configurator also offers access to all the necessary engineering data, simplifying the process for customers.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin