Matrox All-in-One Vision System Aims to Boost Industrial Performance

Matrox Imaging announced the Matrox Iris GTX model edge IoT devices offering performance for a compact all-in-one vision system.

Matrox Iris GTX smart cameras are model edge IoT devices designed to handle traditional machine vision operation and deep learning inference. This “next evolution” of smart cameras from Matrox Imaging boasts an Intel Atom x6000 series embedded processor. This processor enables the Matrox Iris GTX to use the higher-resolution complementary metal-oxide-semiconductor (CMOS) image sensors and provide more processing power than its predecessor.

Matrox Iris GTX Designed for Machine Vision and Deep Learning

Matrox Iris GTX model edge IoT devices will be available in the third quarter of 2021. These smart cameras are designed to caption high-resolution images at a high speed through a choice of CMOS sensors from two to 16 megapixels.

Video used courtesy of Matrox Imaging

To achieve a higher-resolution image capture and more detailed inspection, the Matrox Iris GTX leveraged the Intel x6000 series dual-core embedded processor and the Matrox Design Assistant X flowchart-based vision software.

Thanks to the powerful processor and flexible vision software, the vision tools see an up to three-fold performance boost with Matrox Iris GTX for the same image resolution, compared with its precursor, according to Fabio Perelli, Product Manager from Matrox Imaging.

Machine Vision Applications for Harsh Industrial Spaces

Machine vision technology is widely used within automation and production lines. It enables a computing device with a camera to perform mundane visual inspection tasks, and obtain and process data for controlling, guiding, or evaluating a specific part or activity. This system hopes to reduce human involvement or error in various applications, especially in a hazardous place or clean spaces, to prevent contamination or human injury.

Matrox Iris GTX. Image used courtesy of Matrox Imaging

The typical uses for machine vision include sorting, counting, absence or presence detection, automated vision testing and measurement, robot or machine guidance or monitoring, color verification, defect detection, optical character recognition and verification, pattern matching, data collection, and real-time process control.

Bundled with flowchart-based Matrox Design Assistant X software, the Matrox Iris GTX aims to allow technicians and engineers to quickly configure and deploy machine vision. This software with a web-based operator interface is designed to offer video capture, location, measurement, reading, analysis, verification, communication, and I/O operations.

With a compact IP67-rated design, Matrox Iris GTX fits for working in dirty, humid, or other harsh industrial environments. These smart cameras are designed to perform data acquisition and analytics, real-time digital I/O for interfacing directly to automation devices, and offer guidance or inspection results to the manufacturing process.

Industrial Applications of Smart Cameras

Integrated with AI and deep learning, the examples of machine vision applications in manufacturing include predictive maintenance, vision inspection, package inspection, barcode reading, defect reduction, safety improving, product and components assembly, track, trace, and content analysis.

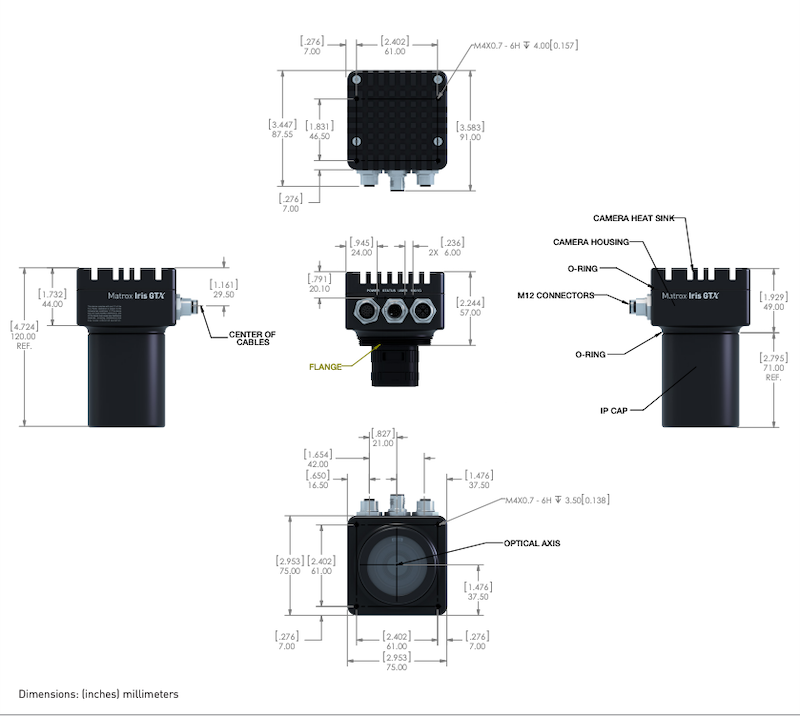

Matrox Iris GTX dimensions. Image used courtesy of Matrox Imaging [PDF]

According to Matrox Imaging, high-speed web inspection systems leverage machine vision to identify defects. For materials like plastics, foils, papers, and non-woven, the AI surface system can detect skips, pinholes, scratches, gels, and other defects. The company planned to develop inspection systems using CMOS cameras supporting higher line speeds.

For visual inspection, the new Matrox Iris GTX smart cameras use deep learning through image classification and segmentation tools. They feature an auto-focus lens for focus adjustment and a LED lighting intensity control output for direct adjustments within the on-device software, which hope to eliminate the need for manual intervention in hard-to-reach spaces. These smart cameras also provide GigE, USB, and VGA connectivity and handle human-machine interface (HMI) functions.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin