Mitsubishi Electric’s Latest Robot Cell Aims to Create Flexible Machine Tending

Their latest addition to their lineup of robotic automation is called the LoadMate Plus, equipped to help engineers with machine tending operations.

Mitsubishi Electric’s Robot Cell

Mitsubishi Electric Automation is headquartered in Vernon Hills, Illinois. They are dedicated to providing different services in the robotics and automation industries that help to provide simple solutions to complex robotic applications. They recently released a new addition to their lineup of robotic automation, called the LoadMate Plus.

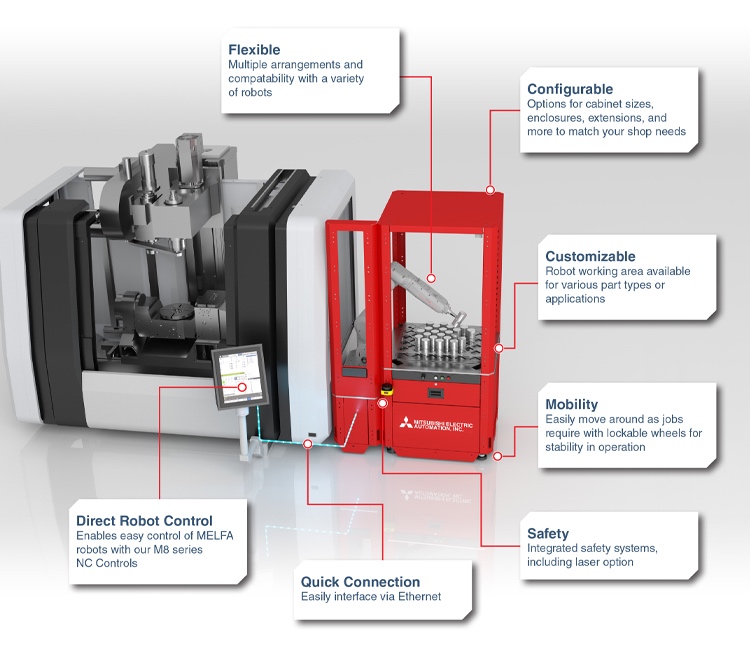

An image showing how the new LoadMate works. Image used courtesy of Mitsubishi Electric Automation

The LoadMate Plus is a mobile unit capable of moving to different stations for increased versatility. The LoadMate Plus was designed with CNC and machine tending in mind. Its features are geared toward creating a solution to a growing labor shortage.

It can reduce the effects of labor shortages and help to improve efficiency and increase production capacity.

LoadMate Plus for Machine Tending

The LoadMate Plus is designed to be useful in machine tending, especially in low volume high mix situations, bringing the benefit of automation to processes that traditionally proved to be too variable. The system can work when it comes to loading and unloading CNC machines and lathes. It can be set up on a single machine or tend two machines if mounted between them.

A diagram showing the new features of the LoadMate. Image used courtesy of Mitsubishi Electric Automation

The robot is mounted on a unique mobile platform that makes it easy to move around. Increased mobility leads to a more versatile system capable of being used for short production runs before moving on to different tasks.

The LoadMate is designed to pair with Mitsubishi's M8 Series CNC. Operators can use the Direct Robot Control (DRC) feature within the CNC to program and control any robot with menus and G-code from the same screen used for the machine tool.

Integration of the LoadMate may be more accessible than some systems since there is no programming experience needed or teach pendant to make the LoadMate operate properly. This helps lower the cost barrier that automation can have for some manufacturing processes since no additional labor or expertise is necessary to integrate into existing processes.

“Most automation solutions for machine tending rely on either cobots for flexibility, or industrial robots for performance and larger parts,” said Rob Brodecki, services product manager at Mitsubishi Electric Automation.

LoadMate Plus Aims to be More Adaptable

The LoadMate Plus is designed to be flexible with different applications. The design of the systems makes for a cell that works well as a standalone cell or can be integrated into bigger system flows.

Mitsubishi also offers guidance for first-time and experienced buyers alike to help get the best fit depending on the application. The LoadMate can also be used for pick-and-place, inspection, assembly, packing, or other applications.

Mitsubishi aims for the new Loadmate to be a versatile and helpful tool for automating many different tasks. Mitsubishi has created a solution that may remain viable in a growing market filled with labor shortages.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin