New Large-Volume, High-temperature 3D Printer From MINGDA 3D

MINGDA 3D has introduced a high-temperature 3D printer with a large print volume and independent dual extruders, intended for producing high-volume, high-quality industrial parts.

A leader in smart 3D printing solutions, MINGDA 3D (MINGDA), has brought out its latest amongst its line-up of 3D printers in the form of an adaptive independent dual extruder (IDEX) 3D printer, the MINGDA MD-400D. The printer accommodates the development and design of complex prototypes for a wide range of industries. Application areas include medical parts, fixtures and jigs, aerospace parts, and more.

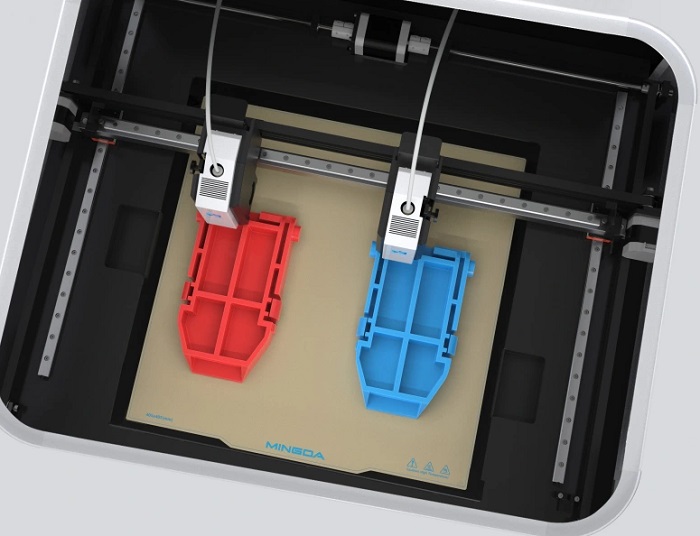

The MINGDA MD-400D IDEX 3D printer. Image used courtesy of MINGDA

Improving Production Efficiency

The MINGDA MD-400D 3D printer features a large print volume with a printing size of 400mm x 400mm x 400mm (nearly 16 inches on each edge). More parts can be generated in a single print run the higher the build volume. A printer featuring a large build volume may produce larger products or print several smaller ones at once, which improves productivity, especially when producing parts at a larger scale.

Users can employ mirror mode for printing symmetrical models or duplicate mode to improve production turnover. The MD-400D 3D printer can also execute support mode or dual color mode for printing complex products and products utilizing two colors, respectively.

An inbuilt IDEX system allows duplicates or different parts to be made simultaneously, boosting production outputs. Image used courtesy of MINGDA

In the world of 3D printing, bed leveling systems serve to prevent failed prints that might occur due to an off-kilter build plate. The MD-400D 3D printer includes an automated calibration procedure to set the bed-to-nozzle distance for extruders to provide highly detailed layer resolution during part printing.

Secure and Intuitive Printing

The MD-400D 3D printer is enclosed in secure housing to maintain printing temperatures for high-quality printing of parts. Maintaining temperatures is key to avoiding warping, broken filaments, model shrinkage, and other issues.

A user-friendly, 5-inch touch screen allows users to navigate and operate the printer. If power is lost, the printer can resume printing automatically from where it left off after power and temperature are restored, minimizing frustrating print failure. If filaments are broken or might run out, the MD-400D 3D printer detects this and alerts the operator, pausing the printing process and avoiding part failure.

A user-friendly interface provides users with intuitive operation. Image used courtesy of MINGDA

IDEX Printers vs. Conventional Alternatives

The MD-400D uses dual extruders that function independently to improve control, with both hot ends reaching a maximum of 350 °C. The printer can use two types of extruders; one for higher temperatures above 250 °C and one for operating below this temperature. For perspective, the super-common PLA plastic used for many models is printed around 200 °C. Some polycarbonate and other materials can exceed 300 °C extruder temperatures.

In comparison to conventional dual-nozzle printers, IDEX 3D printers offer several advantages. The two independent extruders used by IDEX printers allow for the simultaneous printing of two distinct or duplicate models, thereby doubling production. Efficiency is further improved with mirror and duplicate modes, which make it simple to create mirrored (perhaps left-hand/right-hand pairs) or identical pieces.

IDEX printers are adaptable and appropriate for intricate patterns due to their use of soluble supports and the flexibility to print with various nozzle diameters. They print using multiple substrates, providing a range of colors and textures in a single print job. Additionally, because each extruder functions independently, IDEX printers avoid downtime and calibration difficulties. These characteristics make them a favored option for designers looking for flexibility and expanded design choices because they boost time and material efficiency.

IDEX 3D printers stand apart from other dual nozzle models because of their ability to print simultaneously, use materials flexibly, and minimize downtime. They are effective tools for mass manufacturing or projects that call for complicated designs with intricate geometries and provide designers with more creative freedom.

Industrial 3D Printing Applications

The capabilities of the MD-400D 3D printer are ideal for developing and verifying prototype designs. The printing process enables the removal of support filament structures without damaging the end-product and soluble support structures are available for products with hollow internal structures.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin