NVIDIA Isaac and NVIDIA Omniverse Advance AI-Driven Robotics Solutions

NVIDIA continues to advance the integration of artificial intelligence in industrial robotic solutions through new and existing industry partnerships.

Companies are leveraging the capabilities of NVIDIA’s Omniverse and Isaac platforms to animate AI-driven robotics, maximize programming efficiency, and streamline robot deployment. Among the line-up of industrial leaders taking the next step towards a new era of supercharged robotics are Rockwell Automation, Techman Robot, Siemens, and Intrinsic.

Techman Robot is utilizing NVIDIA technology to reduce robot programming and cycle time. Image used courtesy of Techman Robot

AI-Powered Robotics

Techman Robot attended Computex 2024 alongside key industry player NVIDIA on June 4-7, 2024, in Taipei, Taiwan. Among the innovative technological displays, Techman showcased its NVIDIA Omniverse-powered digital twins and vision-system-enhanced TM AI Cobot with integrated AI.

Techman’s TM AI Cobot uses a supercharged AI model trained on thousands of real-world data points (including boxes of different sizes), with 90% of data coming from NVIDIA Isaac Sim in the form of OpenUSD-based synthetic data. The virtual data encompasses interaction possibilities the cobot might encounter, including images of boxes with different materials, prints, and palletized boxes in other conditions.

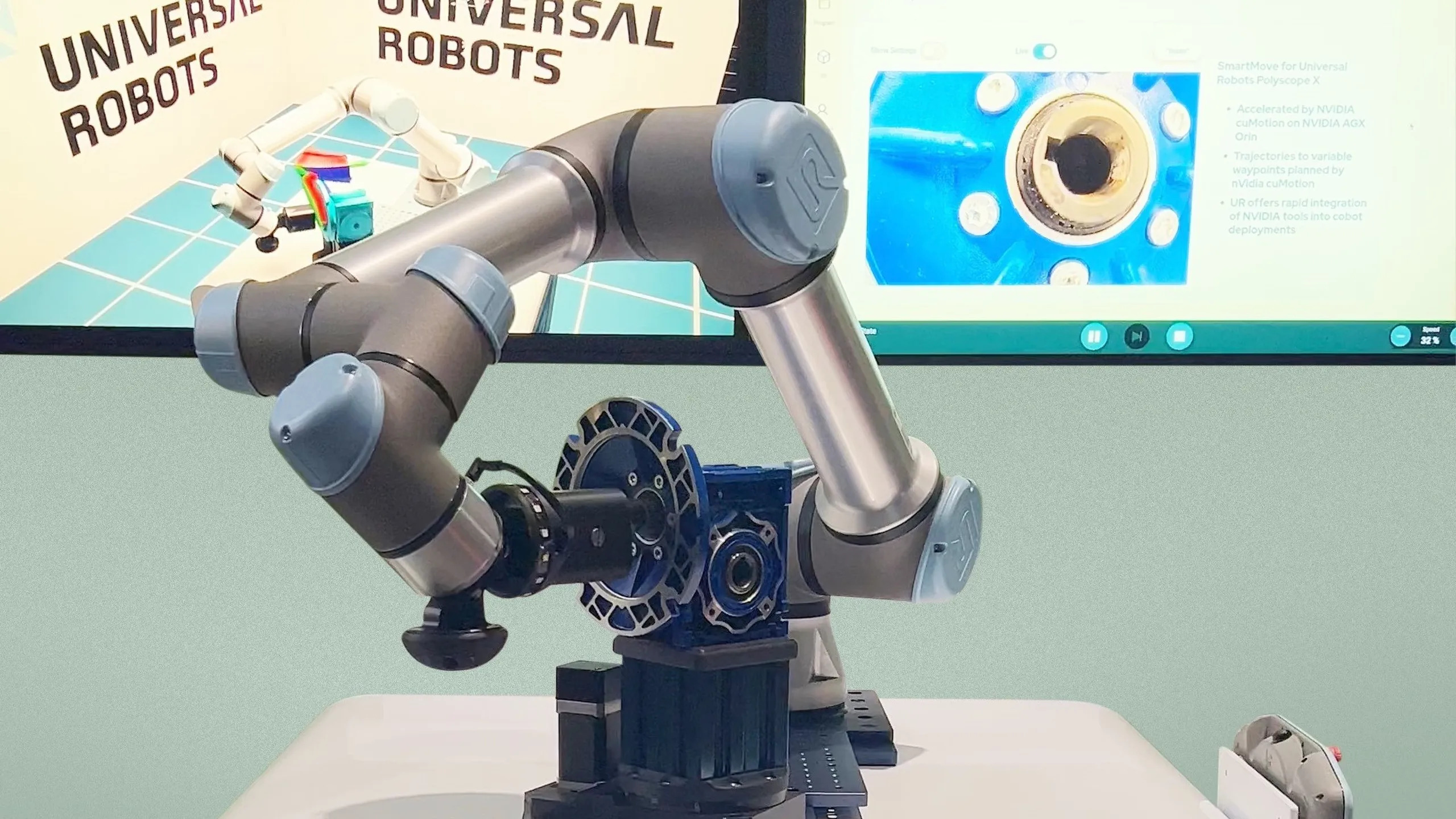

Universal Robots is utilizing NVIDIA technology to drive AI-powered cobot solutions. Image used courtesy of Universal Robots

Unlocking the Next Wave of Robots

In a previous article from Control Automation, we saw how Intrinsic (an Alphabet company) leveraged NVIDIA Isaac Sim for training and testing a vacuum-grasping robot. Siemens is another company leveraging NVIDIA Isaac Sim to test and refine advanced robotics skills such as SIMATIC Robot PickAI, a vision software founded on deep learning algorithms for piece-picking and other applications. Using NVIDIA Isaac Sim allows companies like Intrinsic and Siemens to generate cost-saving synthetic data and speed up the deployment of robotics applications with highly dexterous manipulation capabilities.

Universal Robots, a Teradyne Robotics company, is another Isaac Sim proponent. The company is utilizing NVIDIA’s Isaac Manipulator within its PolyScope X software platform to expand the development of new cobot solutions. Isaac Manipulator is a set of foundation models and general processing unit-accelerated libraries designed for robotics software developers. It facilitates the design and implementation of repeatable, scalable workflows for handling intricate robotic tasks requiring deft manipulation.

Mobile Industrial Robots (MiR), another Teradyne Robotics company, is also using Isaac Sim’s capabilities to simulate its MiR1200 Pallet Jack for autonomous operations in the real world.

Rockwell Automation’s ongoing NVIDIA collaboration sets out to expand the possibilities of mobile robotics. Image used courtesy of Otto Motors

AI in Autonomous Mobile Robots (AMRs)

Rockwell Automation announced the continuation and expansion of its partnership with NVIDIA, employing the Isaac platform to promote the integration of AI in Otto Motors’s AMRs. The goal is to develop and supply the next generation of safety-conscious and data-driven AMRs to help industrial companies improve process efficiencies across their production streams. Intelligent AMRs are intended to support human workers, alleviate labor shortage woes, and empower workers by providing a platform to learn and exercise newly gained skills and knowledge in robotics and automation.

Rockwell also endeavors to enhance its industrial-scale digital twin offering by incorporating NVIDIA Omniverse Cloud application programming interfaces into its Emulate3D software. Doing so will enable users to collaborate in real time, pre-empt potential control issues, and benefit from using a virtual training space to learn a new system.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin