Pleora eBUS Edge Aims to Simplify Sensor Design for Advanced Inspection

Pleora releases a new software integration solution in hopes of simplifying the deployment of inspection systems for robotics, automotive, IIoT, and aerospace industries.

Pleora Technologies Inc. was established in 2000 and serves a range of global markets from industrial automation and security and defense markets. The company specializes in video transmitters and receivers that process data or video streaming in real-time over standard Gigabit Ethernet networks.

Recently, Pleora announced the release of a new software solution that can convert any device into a standardized GigE Vision, GenICam compliant device.

Machine Vision and Inspection Techniques

Machine vision is used in a wide variety of applications. From industrial applications to space exploration, machine vision is a crucial tool.

Parts inspection is one application where machine vision comes in handy. A part inspection is carried out by inspecting the quality of the parts and comparing it with predetermined specifications.

The eBUS Edge logo. Image used courtesy of Pleora

Quality control inspections are often manual and time-consuming. By using machine vision which combines hardware and software technologies, they can be done automatically at much higher speeds.

This has many benefits, including improved efficiency, reduced human error, reduced cost of labor for manual inspection, increased capacity for production due to a decrease in stoppages caused by errors or defects.

eBUS Edge

The software, eBUS Edge, allows machine vision designers to develop imaging systems to deploy an inspection solution without adding additional specialized hardware. This can save on time and costs.

In a recent news release, the Product Manager at Pleora, James Falconer, commented, “eBUS Edge provides significant cost and integration advantages for manufacturers developing advanced inspection systems, including 3D, robotics, motion tracking, barcode reading, industrial drones, and sensor-based measurement.”

Falconer added, “With our ‘zero footprint’ software approach, manufacturers can quickly develop GigE Vision-compliant imaging and sensor solutions that interoperate with other devices and integrate with machine vision processing in multi-vendor systems.”

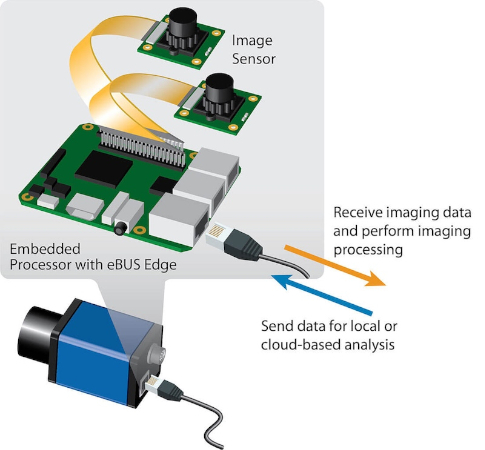

A diagram showing how the edge platform works with sensor and cloud data. Image used courtesy of Pleora

Manufacturers and system engineers can update existing machine vision inspection systems without device limitations, and ensure data and control transmission between cameras, sensors, and embedded platforms for IIoT and Industry 4.0 deployments.

In addition to embedded imaging devices, another application for eBUS Edge is 3D Inspection. Pleora’s eBUS Edge can help convert 3D sensors into GigE Vision devices. The software also allows uncompressed 2D or 3D imaging data to be transmitted using multi-part payloads with low, predictable latency.

With eBUS Receive, users can organize images and data into buffers for hand-off to the end application for further analysis. Developers can use eBUS Receive to write applications that run on a host computer to control and configure a range of GigE Vision, USB3 Vision, and GenICam compliant sensor devices.

Who is Using eBUS Edge?

Sensor manufacturers are using eBUS Edge for 3D inspection of parts and electronics for the automotive, aerospace, and medical industries.

Machine vision designers are also using eBUS Edge In IIoT and robotics applications to produce small form-factor GigE Vision embedded imaging and sensor devices that enable more simplified connection and integration with machine vision processing solutions.

Pleora is hopeful that the new eBUS Edge software will help engineers streamline their machine vision applications.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin