Real-time Fleet Monitoring Emerges with KUKA’s New Platform

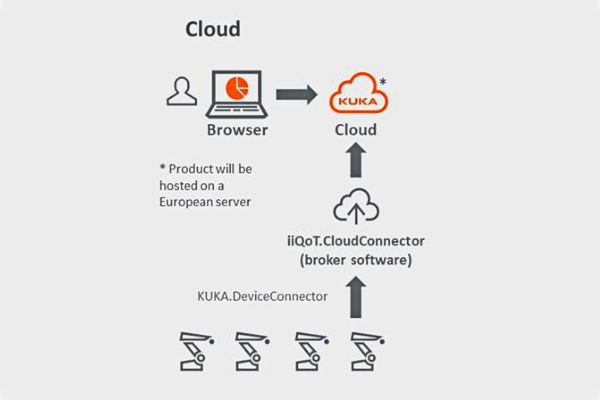

The KUKA iiQoT provides a new cloud-based platform for real-time robot fleet management and optimization.

KUKA AG (KUKA) is a German company specializing in providing factory automation solutions for its global network of customers. The company’s product offering includes industrial robots with varying payload capacities and reaches, production machines, and tailored production systems. Recently, KUKA introduced its new Smart factory-enabling IIoT platform, KUKA iiQoT.

The KUKA iiQoT platform

KUKA’s new software platform allows KUKA customers to implement systems management, maintenance, fault detection, and condition monitoring. It is designed for small and large robot fleets and is initially available as a Software as a Service (SaaS) cloud solution.

A KUKA robot working in the new platform. Image used courtesy of KUKA

Customers can add and remove robots to suit desired operations and access the latest version of KUKA iiQoT without hardware costs.

Customers can use the new platform to bring in robot fleet data into one dashboard in real-time. This allows for remote access at any time and provides a way of minimizing downtime. KUKA iiQoT users can expect optimal interaction modules including “Condition Monitoring,” “Fault Diagnosis,” and “Changelog.”

In a recent news release, the Portfolio Manager at KUKA, Dr. John Flemmer, said, “The modules provide transparency and clarity across the entire fleet.” Flemmer added, “This provides you with valuable functions according to your industrial application needs.”

The interface of the new KUKA iiQoT platform. Image used courtesy of KUKA

Fault finding and troubleshooting provide customers with notifications concerning any problems. This means that time can be saved during fault finding, the meantime to repair can be reduced, and production losses can be minimized. Operators and manufacturing or warehouse facility managers can use data insights through IIoT to keep an eye on fleet status to maintain productivity or even improve processes and take targeted action to do so.

Predictive Maintenance

KUKA iiQoT’s Asset Manager module provides users with an overview of relevant information on hardware, software, and controller. Robots can be located and classified with user-defined attributes such as the specific application they are being used for.

KUKA iiQoT, customers can add or remove robots to their fleet. Image used courtesy of KUKA

The maintenance manager module can help identify present and future maintenance requirements of all systems and machines. Users can gather current and historical data for robots to search for any trends and irregularities with KUKA iiQoT’s Conditioning Monitoring module.

Additionally, control and mechanical data can be captured and visualized. Other modules, including messages, notifications, and more, help users predict any maintenance required and jump to any system faults as quickly as possible to maintain fleet performance.

KUKA plans to expand KUKA iiQoT to cover other areas of predictive maintenance, including information concerning the wear of gear units and motors, as well as workload. Functions concerning energy consumption and cycle time are also planned to be added in the future. KUKA also wishes to integrate digital services such as KUKA Xpert into KUKA iiQoT to enhance the platform.

KUKA is hopeful that this new system will bring IIoT and robots together through one platform.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin